Method and device for fixing salt core for piston casting

A technology for fixing devices and fixing methods, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of easy adsorption of water vapor, long exposure time, low efficiency, etc., and achieve manufacturing cost saving, convenient operation, and simple positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

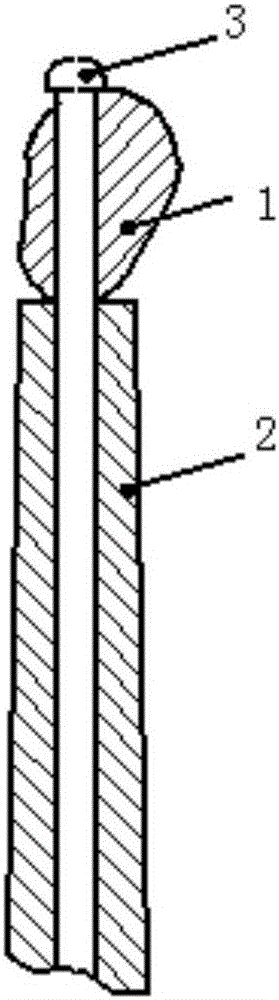

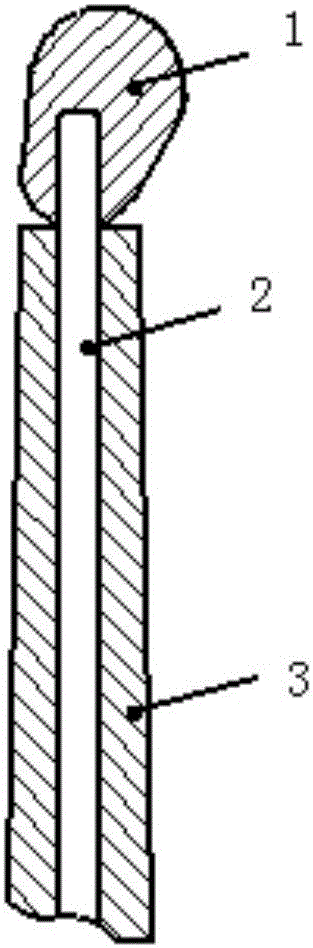

[0023] This specific embodiment provides a method for fixing the salt core of piston casting, which can quickly and conveniently install the salt core on the mold, and avoid adverse effects on the structure of the cast-formed part due to fixing the salt core. The specific embodiment also provides a piston casting salt core fixing device.

[0024] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

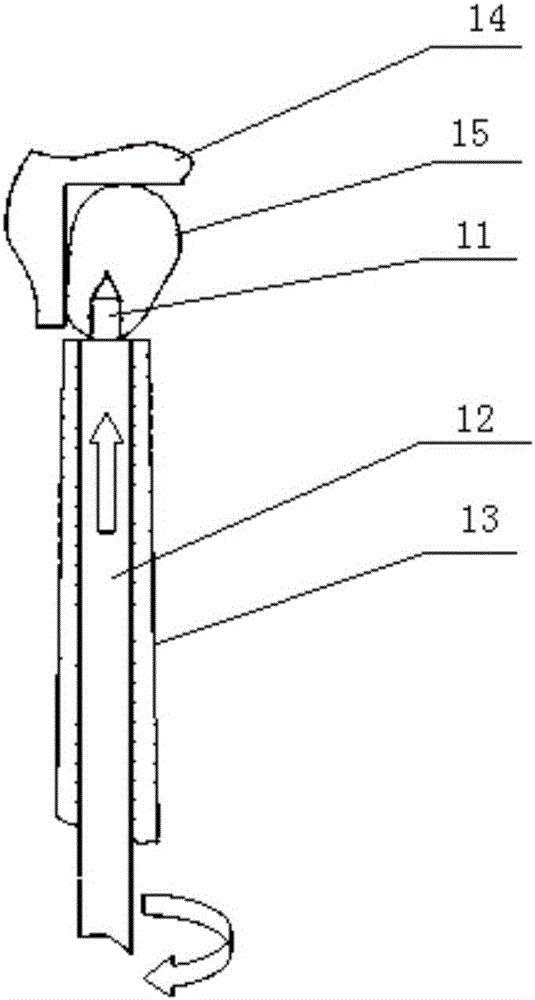

[0025] Please refer to image 3 , the piston casting salt core fixing method provided by the present embodiment comprises the steps of:

[0026] Position the connecting nail 12 with the top 11 and self-tapping thread at the top in the positioning hole of the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com