Bacteriostatic building concrete manufacturing process

A production process and concrete technology, applied in the field of building materials, can solve the problems affecting concrete performance, moldy concrete body, green appearance, etc., and achieve the effects of good water absorption, excellent antibacterial performance, and excellent air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

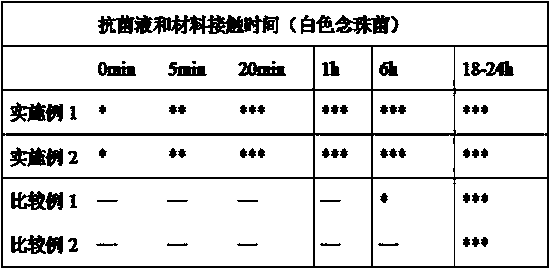

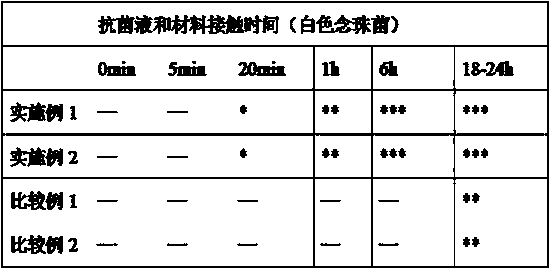

Examples

Embodiment 1

[0030] Step 1. Preparation of antibacterial solution

[0031] The first step, the preparation mass percentage concentration is respectively the methyl cellulose aqueous solution of 5% and the copper sulfate solution that mass percentage concentration is 8%, for subsequent use;

[0032] In the second step, under microwave vibration or high-speed stirring, slowly add chitosan to the above-mentioned copper salt solution, and keep microwave vibration or high-speed stirring for 30-120min to obtain mixed solution A; wherein, chitosan is mixed in mixed solution A The mass fraction in is 10%;

[0033] In the third step, under ultrasonic vibration or high-speed stirring, the above-mentioned mixed solution A is slowly added to the above-mentioned methyl cellulose aqueous solution in a volume ratio of 7:4;

[0034] Then, at 40°C, ascorbic acid was added to react for 45 minutes according to the molar ratio of copper ions to 1:1.2, and then 2-3% pectin and 5-8% sodium alginate were added ...

Embodiment 2

[0042] Step 1. Preparation of antibacterial solution

[0043] The first step, prepare the methyl cellulose aqueous solution that mass percentage concentration is 10% and the copper sulfate solution that mass percentage concentration is 11% respectively, for subsequent use;

[0044] In the second step, under microwave vibration or high-speed stirring, chitosan is slowly added to the above-mentioned copper salt solution, and microwave vibration or high-speed stirring is maintained for 120 minutes to obtain mixed solution A; wherein, the amount of chitosan in mixed solution A The quality score is 10%;

[0045] In the third step, under ultrasonic vibration or high-speed stirring, the above-mentioned mixed solution A is slowly added to the above-mentioned methyl cellulose aqueous solution in a volume ratio of 7:4;

[0046] Then, at 40°C, ascorbic acid was added to react for 45 minutes according to the molar ratio of copper ions to 1:1.2, and then 2-3% pectin and 5-8% sodium algina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com