Automatic air pressure control safety device

A safety device and air pressure technology, which is applied in the field of automatic control air pressure safety devices, can solve problems such as easy air leakage, inaccurate pressure control, and valve wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]Next, the technical solutions in the embodiments of the present invention will be described in connext of the embodiments of the present invention, which is apparent from the embodiments of the present invention, and is apparent from the embodiments of the present invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

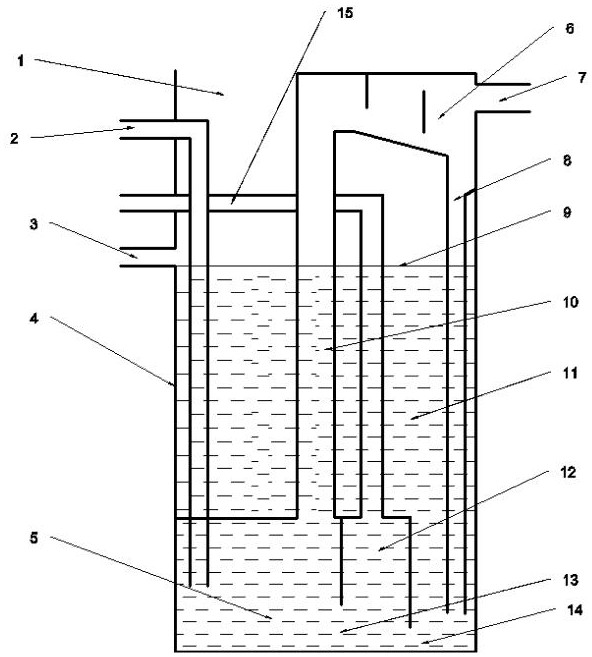

[0017]Such asfigure 1As shown, the present invention provides an automatic control gas liquid separation device, including the left side of the case (4), respectively, an intake pipe (2), a liquid level tube (3), an inlet opening (1) . The casing (4) is provided with a No. 1 gas collection box (5), and the air tube (2) passes through the left side of the case (4) into the 1st gas collection box (5), one gas collection box (5) and Liquid Separation Box (6) communicate through the intermediate inner interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com