A main and auxiliary cavity type garbage jam prevention device for electric sweeper

A sub-cavity and anti-jamming technology, applied in cleaning methods, road cleaning, construction, etc., can solve the problems of increased instantaneous power of conveying motors, reduced operating efficiency, hidden safety hazards, etc., to reduce quality, improve life, and solve blockage problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

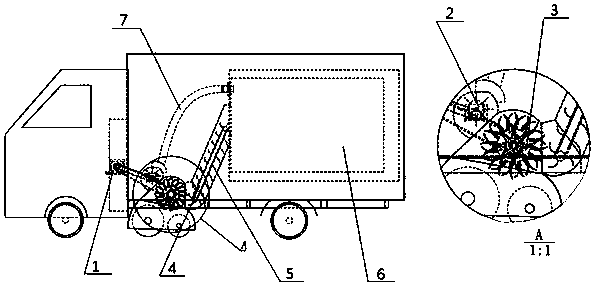

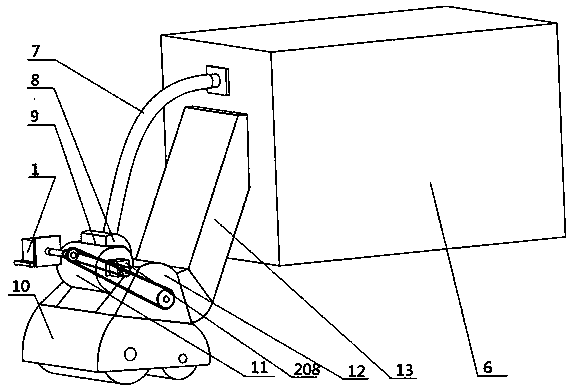

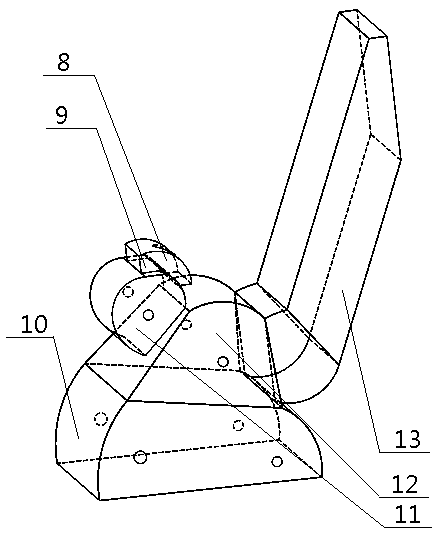

[0016] In the embodiment of the present invention such as figure 2 , 3 , 5. The present invention relates to an anti-jamming device for main and auxiliary chambers of electric cleaning vehicles, which includes a cavity installed on the vehicle frame. The cavity includes a main cavity, and an anti-seize guide wheel 3 is installed in the main cavity. 3 includes three impellers 303 on the left, middle and right, the impeller 303 is installed on the impeller shaft, the impeller shaft 302 of the left end impeller and the impeller shaft 311 of the right end impeller are respectively installed on the main cavity, and the impeller 303 is equipped with conveying blades 305, 308 The opening of the lower cavity 10 of the main cavity is equipped with two roller brushes; the openings at the left and right ends of the main cavity are also connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com