Waste heat recovery system, waste heat recovery method and boiler system

A waste heat recovery system and hot end technology, applied in heating systems, heating methods, preheating, etc., can solve problems such as rust, blocked air duct smoke exhaust, and easy corrosion of heat exchangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

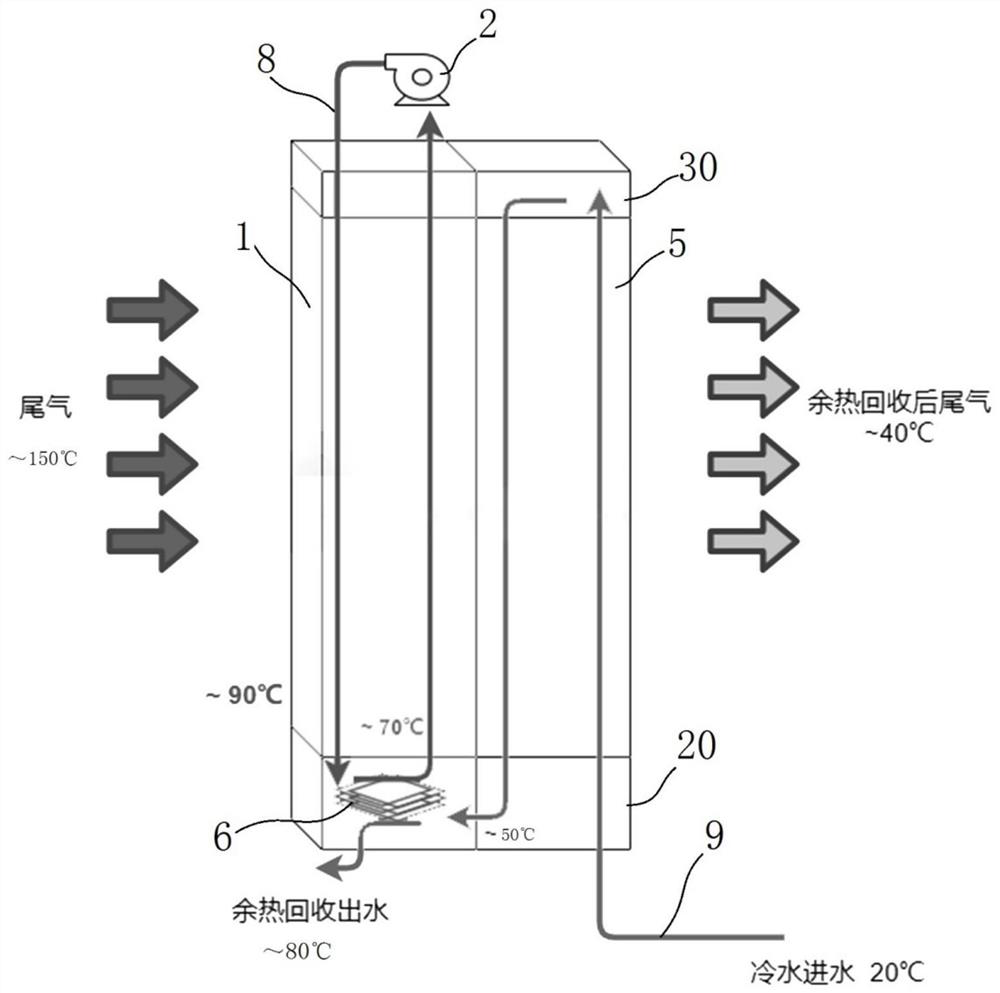

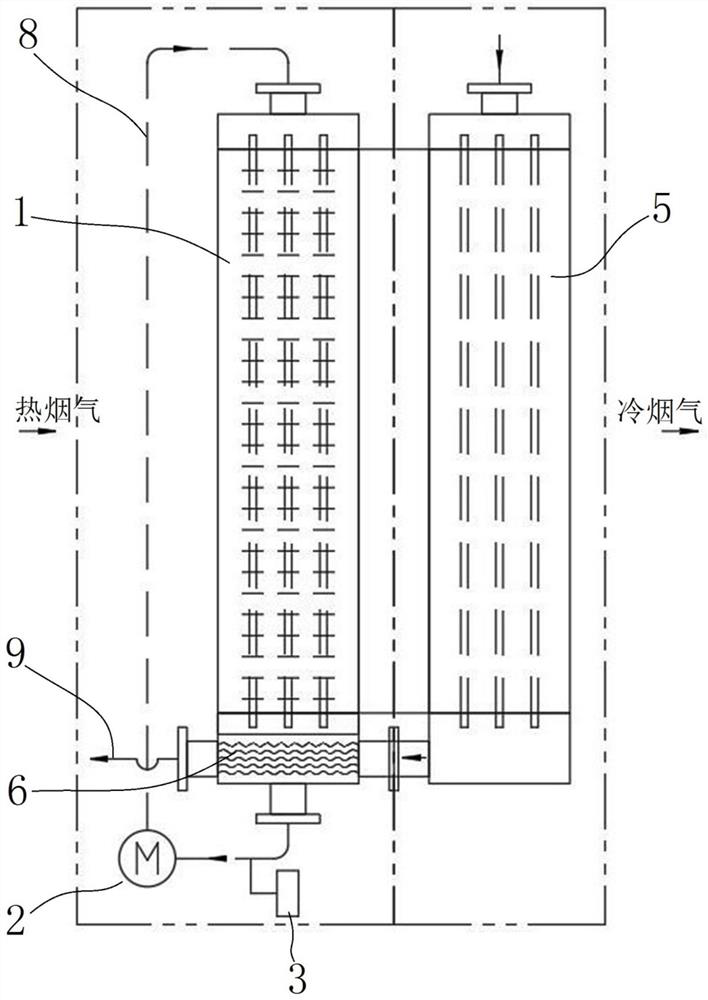

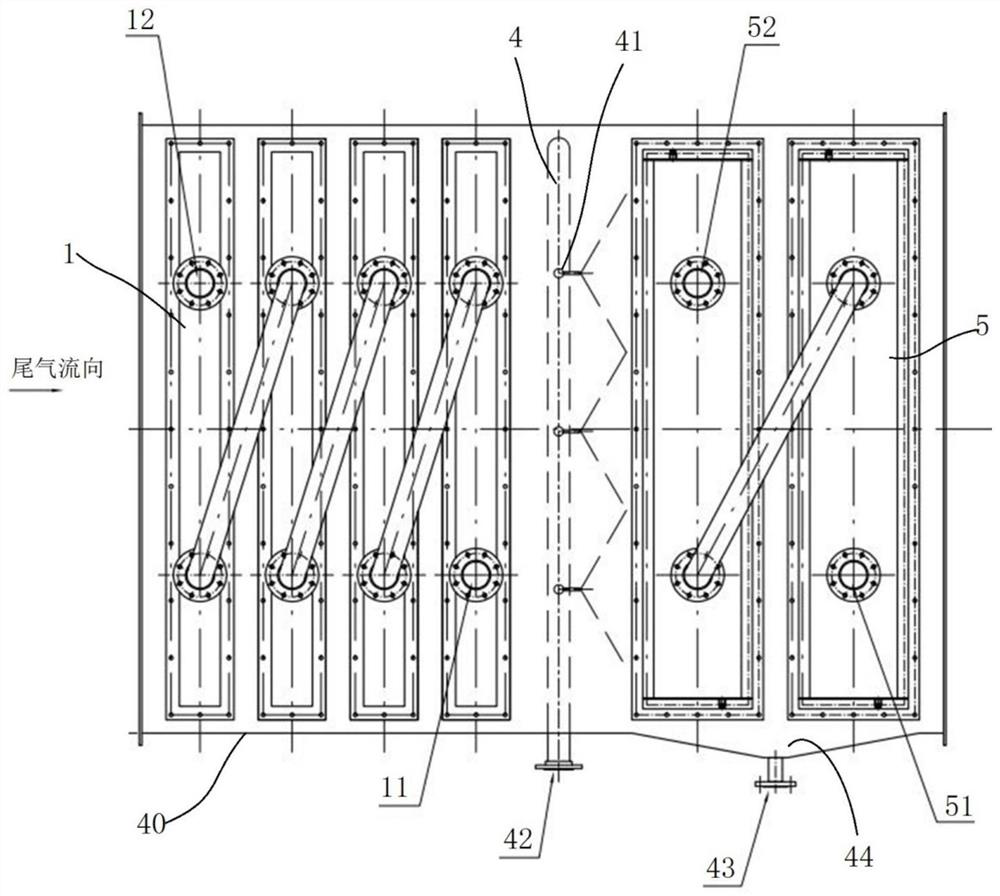

[0051] The waste heat recovery system is used to recover waste heat from the exhaust gas of gas-fired boilers or coal-fired boilers. It has a shell 40, which is pipe-shaped and connected in series in the exhaust gas pipeline, that is, the two ends are respectively sealed and docked with the exhaust gas pipe, so that the boiler The exhaust gas can pass through the waste heat recovery system. After heat exchange, the exhaust gas is discharged. The heat in the exhaust gas is transferred to the heat transfer medium of the waste heat recovery system, and the heat of the heat transfer medium is used for heating, etc., to realize the secondary use of heat.

[0052]The waste heat recovery system includes: a first heat exchanger, which is arranged in the flue, and has a first internal pipeline, and the first internal pipeline is filled with a first heat exchange medium, and the temperature of the first heat exchange medium is higher than that of the water in the flue gas The dew point t...

Embodiment 2

[0080] Embodiment 2 of the waste heat recovery system of the present invention: as Figure 5 As shown, the difference from Example 1 is that a fourth heat exchanger 7 is also provided after the second heat exchanger 5 to solve the whitening problem, specifically: the fourth heat exchanger 7 is an empty water exchange Heater, since there is basically no condensation here, it is also possible to use a heat exchanger made of ordinary carbon steel + galvanized to reduce costs. The heat exchange medium in the fourth heat exchanger 7 is the second heat exchange medium 9, That is, part of the second heat exchange medium 9 is introduced into the fourth heat exchanger 7 after heat exchange in the third heat exchanger 6, so as to realize the reverse heating of the exhaust gas, referred to as recuperation, and the exhaust gas can be reheated after reheating Whitening effect.

[0081] The working principle of whitening here is as follows: After passing through the second heat exchanger 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com