A high-memory microfiber armor coating anti-corrosion method

A technology of memory fiber and armor, which is applied in the field of anti-corrosion coating of high-memory microfiber armor, which can solve the problems of serious safety hazards, prone to pores in the FRP coating layer, and inconvenient construction, so as to block the intrusion of corrosive media and prevent corrosion Excellent protective effect and excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0057] The steel pipe pile protection of the offshore wharf with a diameter of 1.2 meters has a protection length of 3.5 meters.

[0058] The steps are as follows:

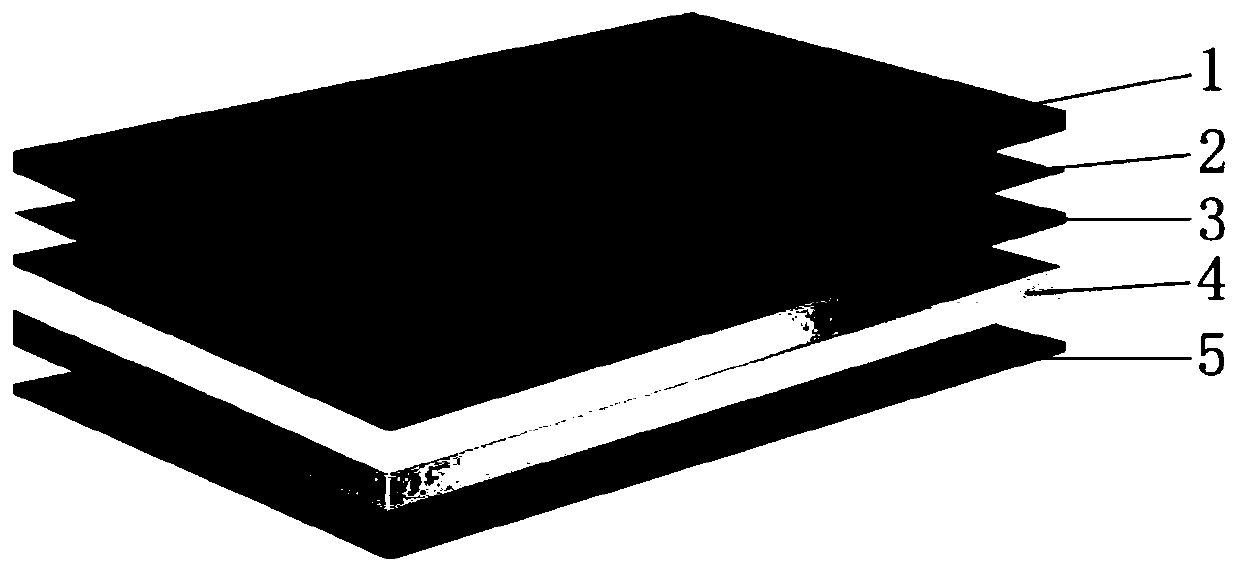

[0059] S1: The cut microfiber armor has a length of 3.5 meters and a width of 3.5 meters. The microfiber armor includes: a high-strength protective outer layer 1, a high-memory fiber layer 2, a buffer protective layer 3, and a solid oil layer 4.

[0060] The high-strength protective outer layer 1 is set as one layer, the high-memory fiber layer 2 is set as one layer, the slow protective layer 3 is set as one layer, and the solid oil layer 4 is set as one layer.

[0061] S2: Use a shovel to remove sea creatures, old coatings and rust layers on the surface of the steel pipe piles.

[0062] S3: Unfold the microfiber armor, wrap it in the steel pipe pile protection area, and fix it with 12 high-strength polymer self-locking lashing straps 7. The distance between every two self-locking straps 7 is 30cm.

specific Embodiment approach 2

[0064] The 5m diameter offshore wind power foundation steel pile is anticorrosive, and the protection length is 6m.

[0065] The steps are as follows:

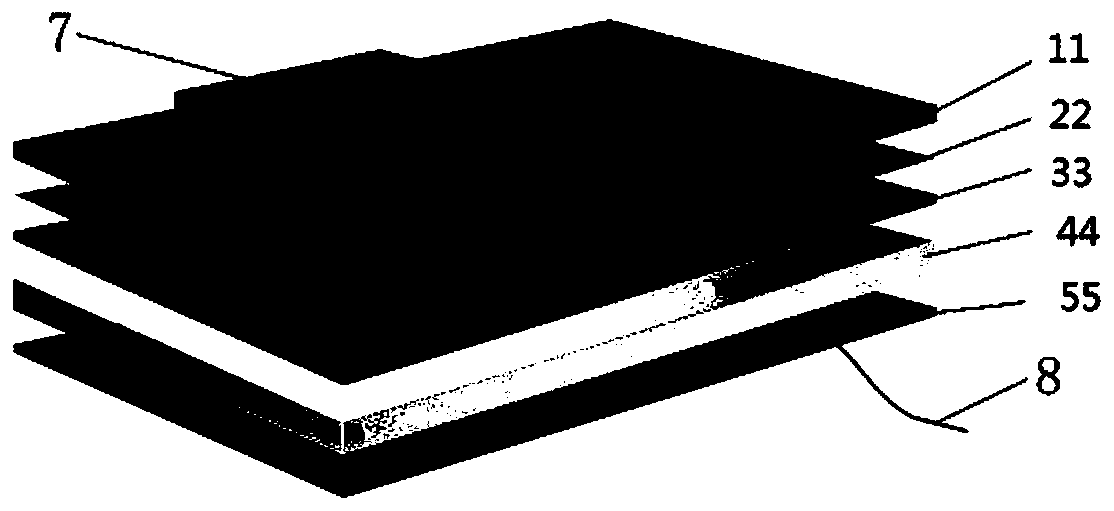

[0066] S1: The cut microfiber armor has a length of 14.5 meters. There are 8 microfiber armors, 4 of which are 3.2 meters wide and 4 are 3.0 meters wide. Both ends are stitched with equal-length flanges.

[0067] The microfiber armor is set as a double layer, and the structure includes: a high-strength protective outer layer 1, a double-layer high-memory fiber layer 2, a double-layer cushioning protective layer 3, and a solid oil layer 4.

[0068] The high-strength protective outer layer 4 is set as one layer, the high-memory fiber layer is set as two layers, the buffer protective layer 1 is set as two layers, and the solid oil layer is set as one layer. The solid oil layer 4 is completely saturated with anticorrosive petrolatum.

[0069] S2: Use a high-pressure water gun to remove sea creatures, weakly attached old coatings, and rust l...

specific Embodiment approach 3

[0072] It is protected by rectangular offshore reinforced concrete piles with a side length of 0.5 meters, and the protection length is 3.5 meters.

[0073] The steps are as follows:

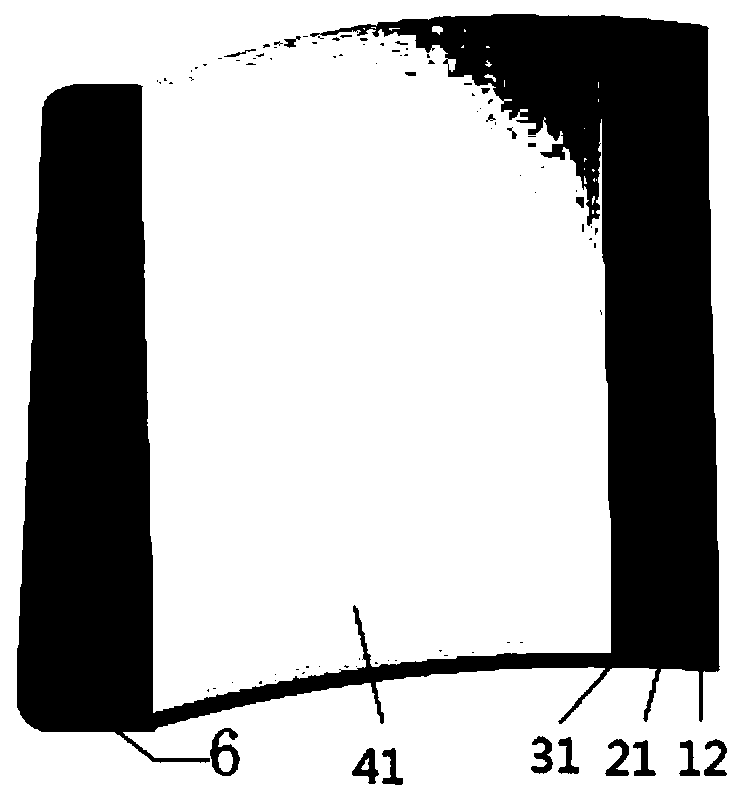

[0074] S1: The cut microfiber armor has a length of 1.85 meters and a width of 3.5 meters. The microfiber armor includes: a high-strength protective outer layer 1, a high memory enhancement layer 2, a buffer protective layer 3, a solid oil layer 4, and a sacrificial anode layer 5.

[0075] The high-strength protective outer layer 1 is set to 1 layer, the high memory enhancement layer 2 is set to 1 layer, the buffer protective layer 3 is set to 1 layer, the solid oil layer 4 is set to 1 layer, and the aluminum alloy sacrificial anode layer 5 is set to 1 layer. Armor two-section suture flange 6

[0076] S2: Use high-pressure water to remove the attachments and loose concrete layers on the pile surface.

[0077] S3: Unfold the microfiber armor, wrap it in the pile protection area, and fix it with high-stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com