Efficient cyclone dust collector with double-layer side wall

A cyclone dust collection, high-efficiency technology, applied in the direction of the cyclone device, the device in which the axial direction of the cyclone can be reversed, etc., can solve the problems of increased energy consumption and reduced dust collection efficiency, and achieves low production and maintenance costs. The effect of reducing pressure loss and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

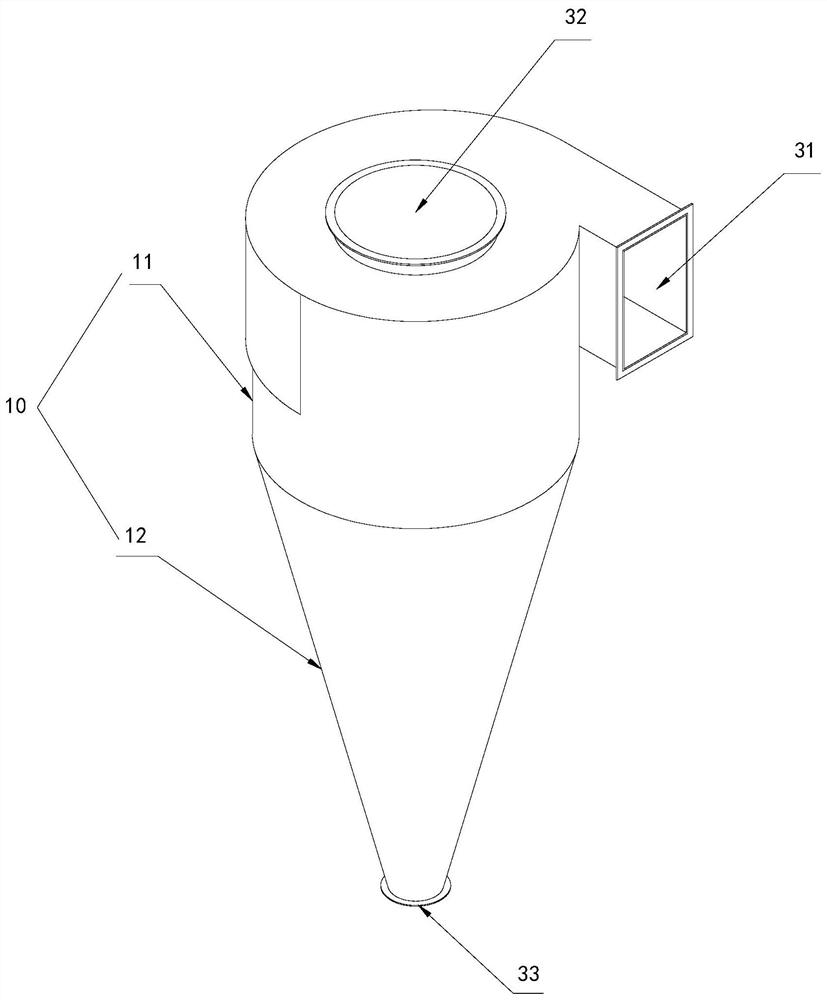

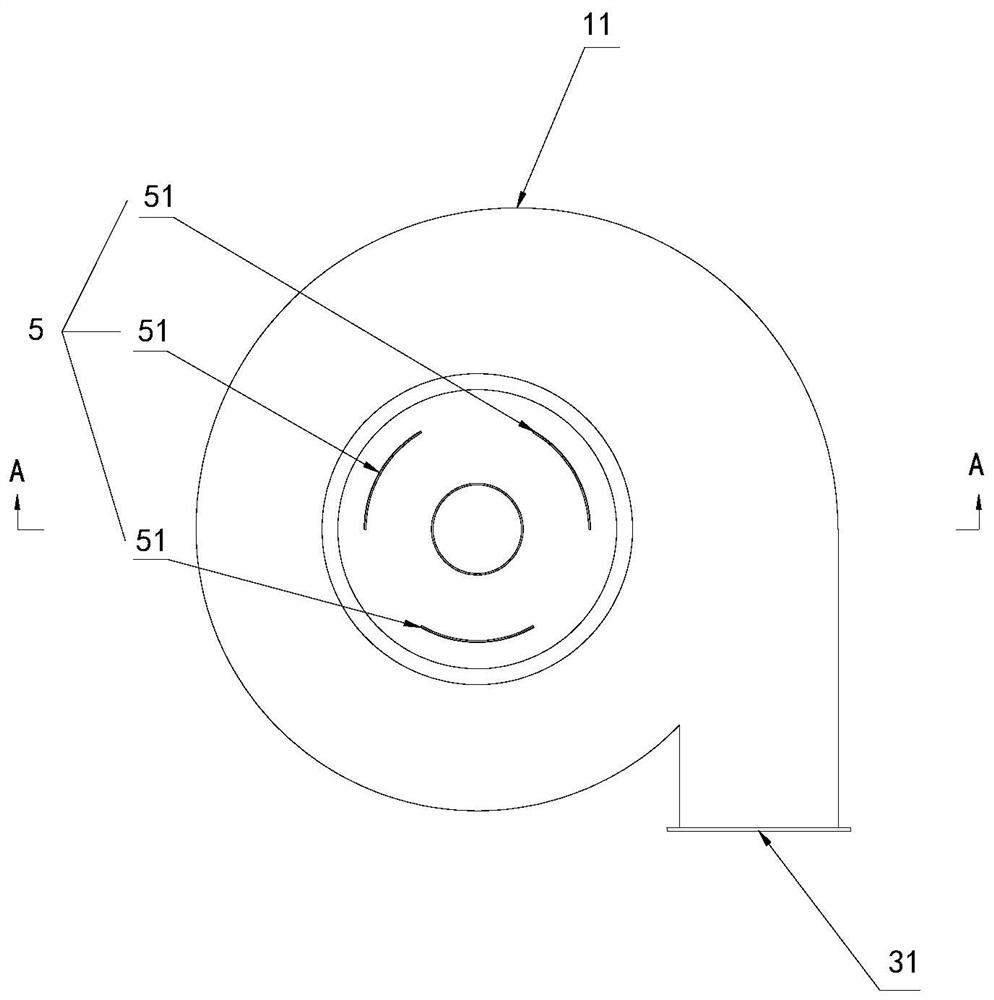

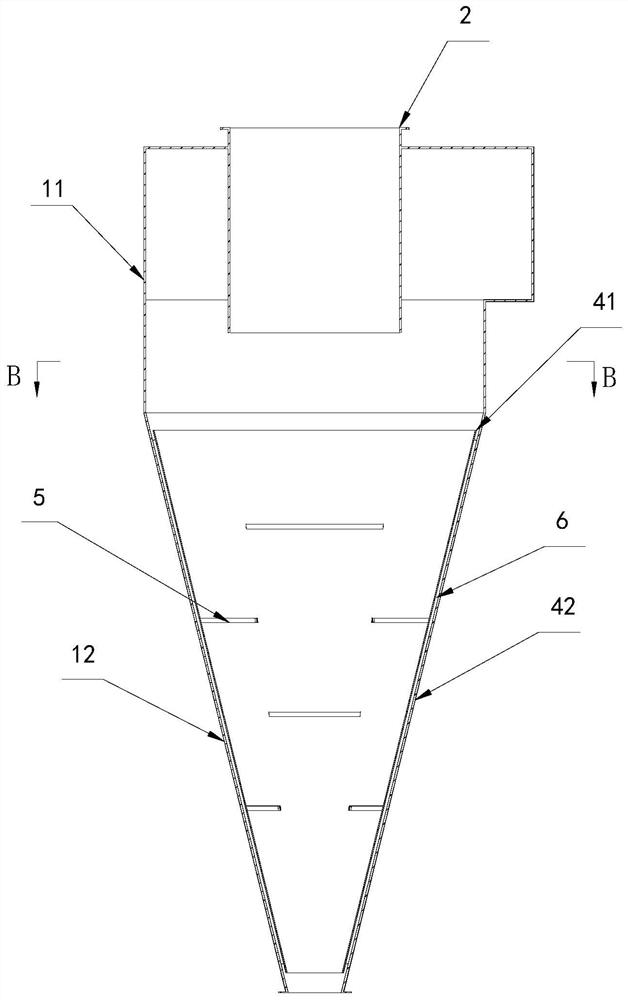

[0051] see Figure 1-Figure 5, this embodiment proposes a double-layer side wall high-efficiency cyclone dust collector, including a housing 10, the housing 10 includes a cylindrical portion 11 and a cone 12, and the cylindrical portion 11 is located at the end of the cone 12 above, and the cylindrical portion 11 communicates with the cone 12, the cone 12 is a cone, the cylindrical portion 11 is compatible with the cone 12, and the cylindrical portion 11 The outer diameter is equal to the maximum outer diameter of the cone 12 . Described cylindrical part 11 is provided with hollow inner tube 2, and described inner tube 2 is arranged vertically, and one end of described inner tube 2 stretches out the top surface of described cylindrical part 11; A gas inlet 31 is provided on the side, and a pellet outlet 33 is provided below the cone 12. The cone 12 includes an inner side wall 41 and an outer side wall 42, and the interlayer between the inner side wall 41 and the outer side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com