Mineral sorting device and mineral processing system

A mineral sorting and sorting device technology, which is applied in the direction of solid separation, separating solids from solids with airflow, and filtering, etc., which can solve the problems of increasing mineral processing costs, limited dust removal effect, and unsatisfactory mineral quality, etc. problems, to achieve good dust removal effect, improve dust removal effect, and significant effect of dust raising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

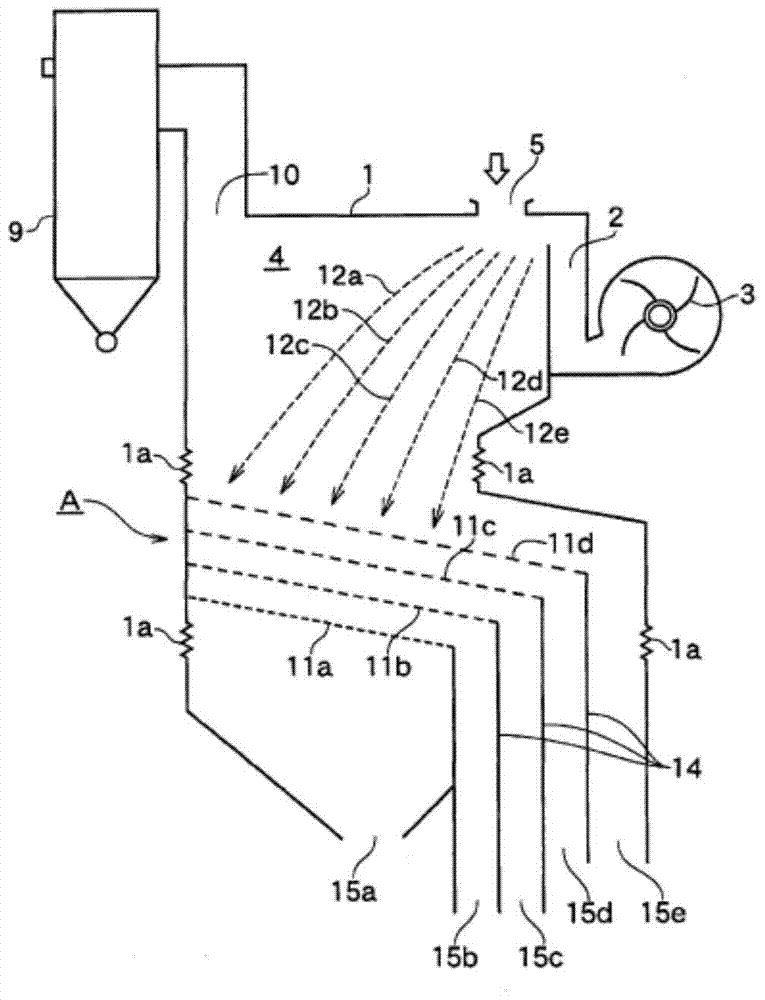

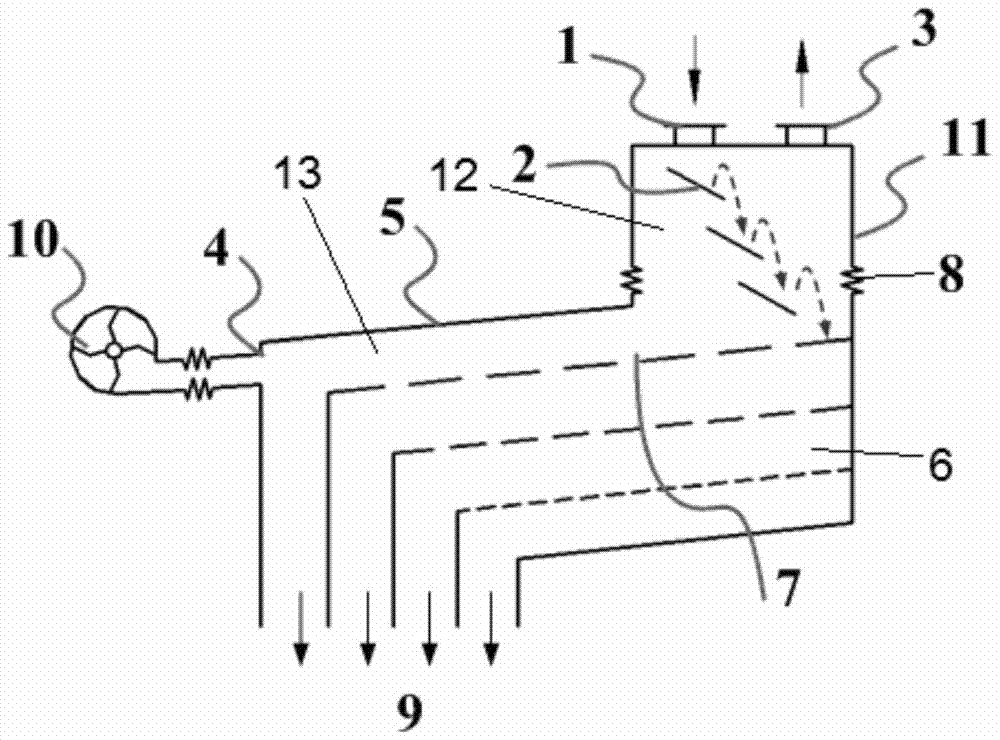

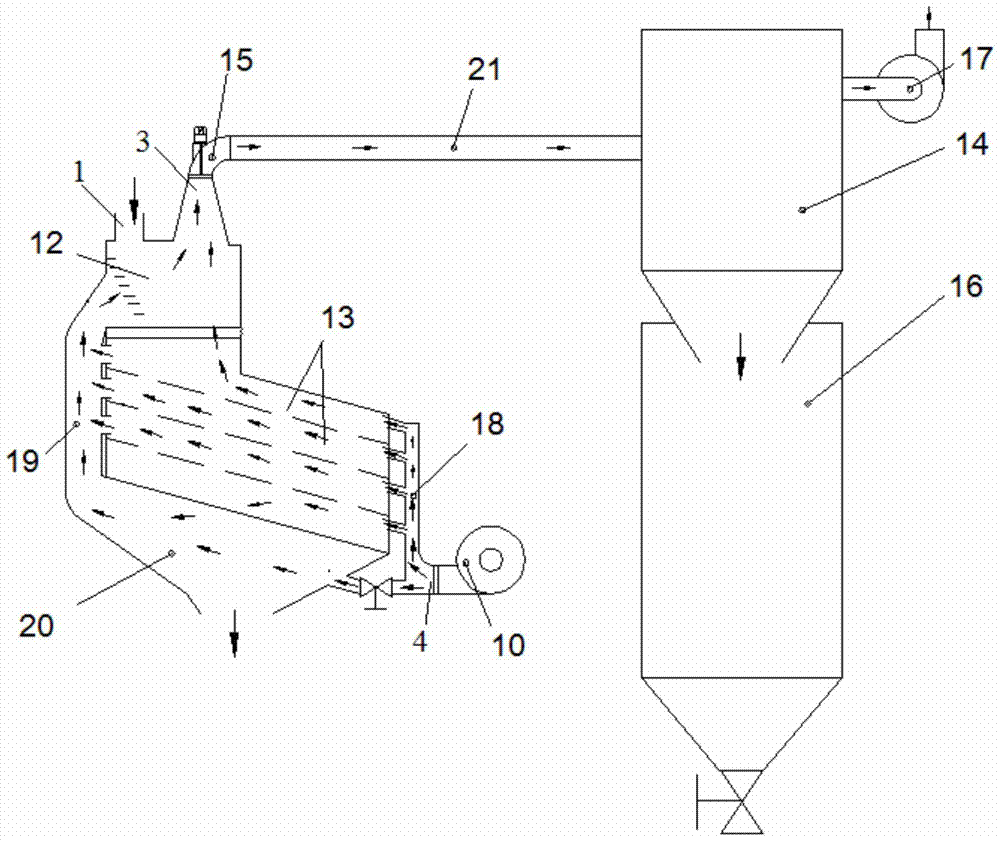

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0040] In the following description, in order to more clearly describe some orientation words involved in the technical solution of the present invention or technical features containing orientation, such as "falling", "uppermost", "upper", "bottom", "lowermost" " etc. are all technical meanings according to the orientation of the mineral sorting device of the present invention during use. No matter how the orientation of the mineral sorting device is placed during production and transportation, as long as it is equivalent to the technical features of the present invention according to the installation ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com