No-air-source foam plug dust removing system applied to underground coal mine

A technology of dust removal system and foam, applied in the fields of dust prevention, mining equipment, safety devices, etc., can solve the problems of polluted working environment, complex structure, low dust reduction rate, etc., and achieve the effect of easy disassembly, convenient assembly, and isolation of foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

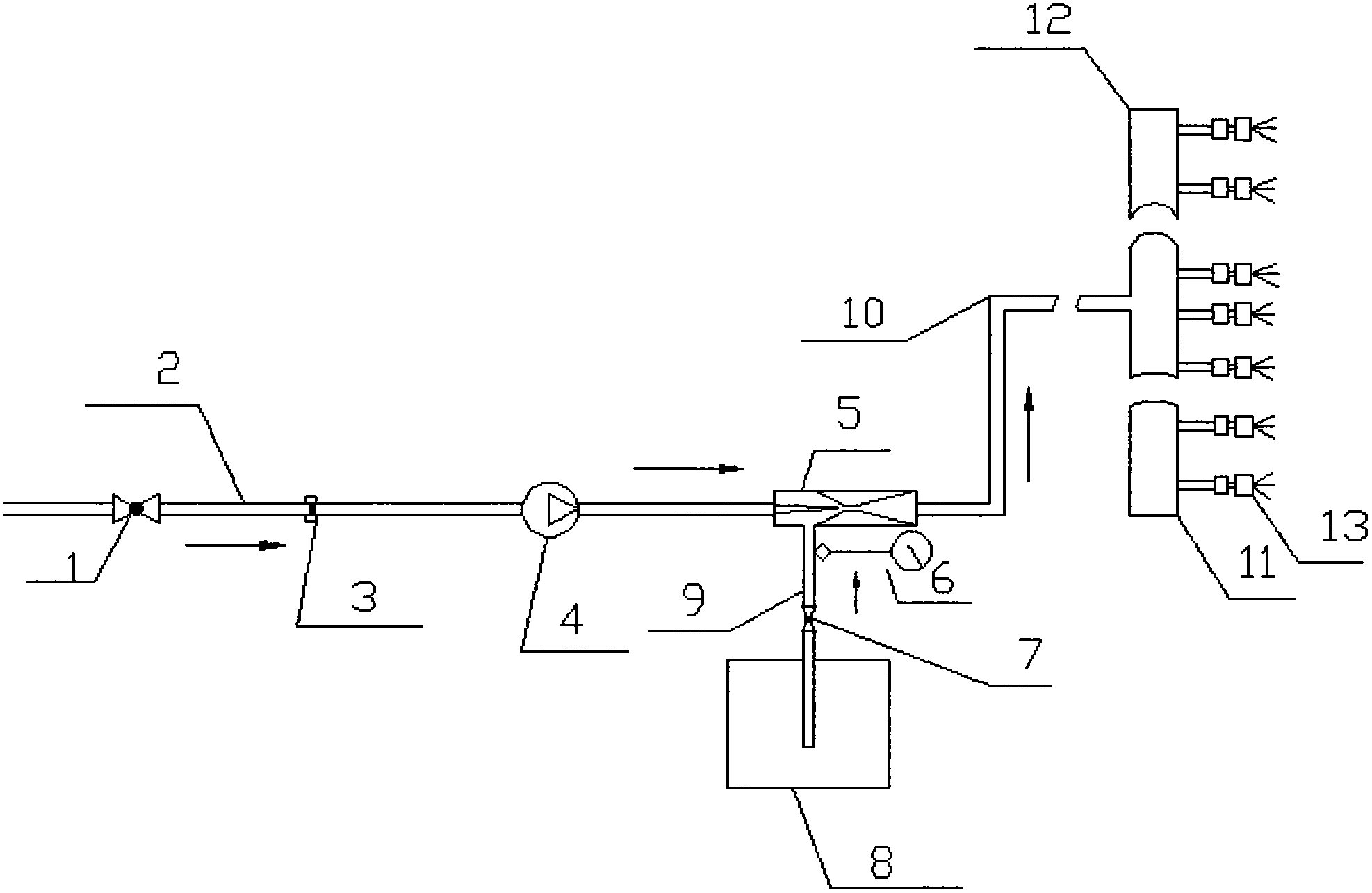

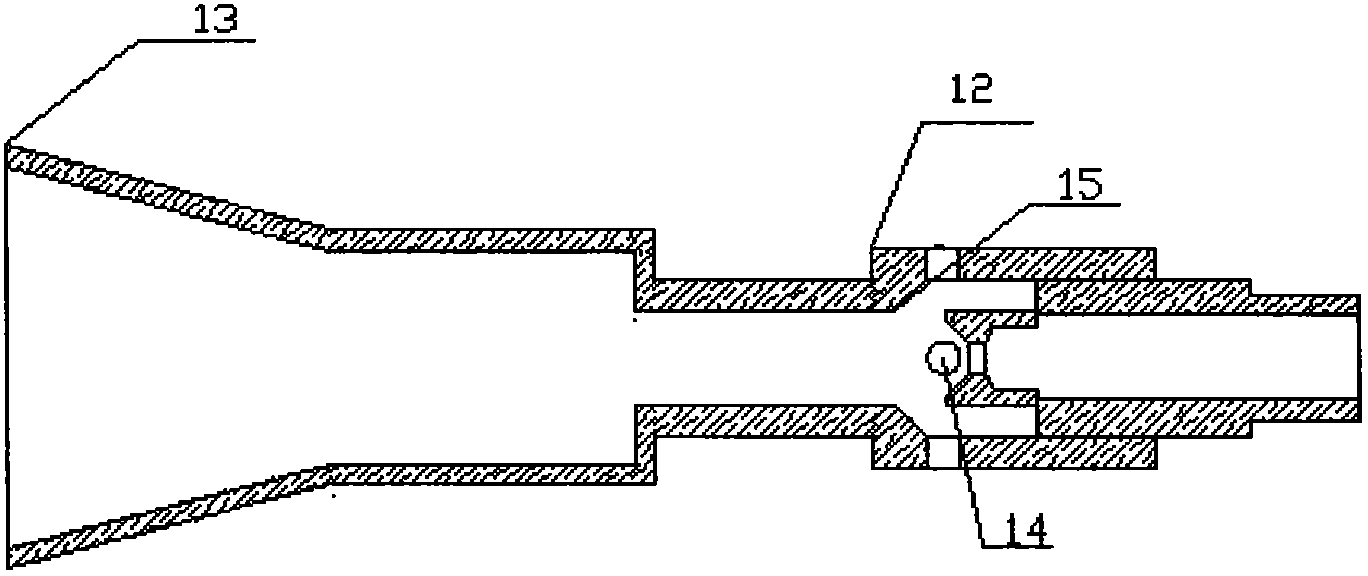

[0009] Attached below figure 1 and attached figure 2 An embodiment of the present invention is further described:

[0010] figure 1 As shown, the system is mainly composed of mine explosion-proof pressurized pump 4, foam agent liquid storage tank 8, proportional mixer 5, foam liquid distribution device 11, foam generator 12 and foam nozzle 13; The explosion booster pump 4 is connected with the clean water pipeline 2 and the proportional mixer 5, and the clean water pipeline 2 is provided with a regulating valve 1 and a filter screen 3 in turn; the foam agent liquid storage tank 8 is connected to the proportional mixer 5 through the foam agent pipeline 9 The foam agent pipeline 9 is provided with a regulating valve 7 and a flow meter 6 in sequence; the foam liquid pipeline 10 is connected with the outlet of the proportional mixer 5, and the other end is connected with the foam liquid distribution device 11; and the foam generator 12 and the foam spray head 13 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com