Waste gas dedusting device and method for tunnel kiln

A technology of a dust removal device and a tunnel kiln, which is applied in the chemical industry, can solve the problems of poor dust removal and filtering effect, poor particle removal ability, and difficulty in cleaning, etc., and achieves the effect of reducing water loss, simple installation and good dust removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

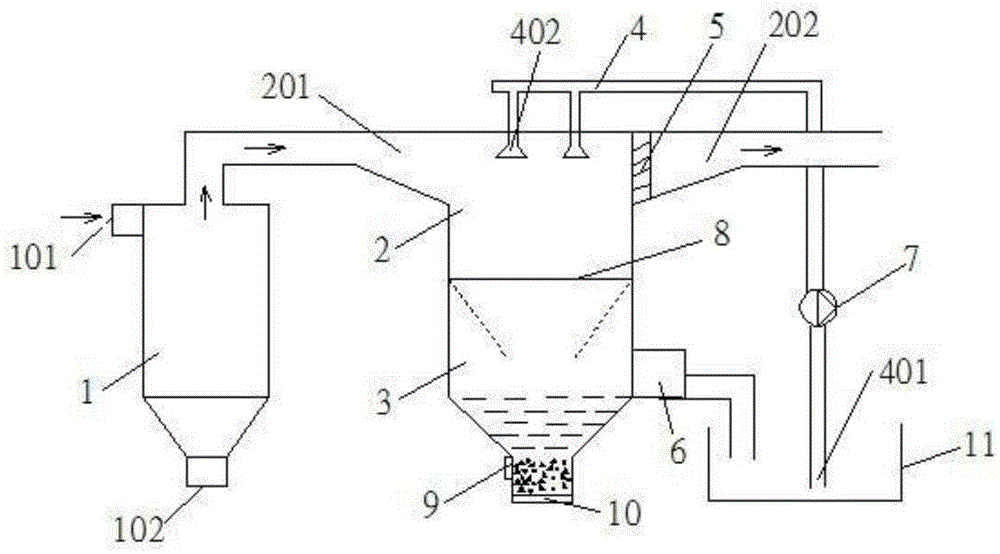

Embodiment 1

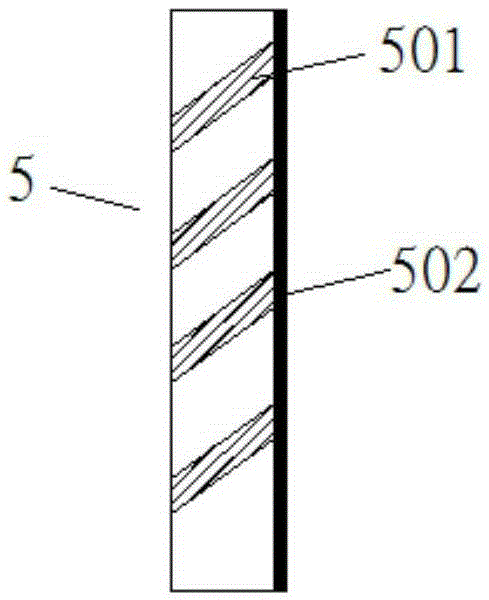

[0032] Open the atomizing shower 4, the switchable partition 8 at the entrance of the dust collection chamber 3 and the switch at the outlet of the purifier 6. The dust concentration passed into the exhaust gas inlet 101 of the cyclone separator 1 is 2483 mg / m 3 The simulated tunnel kiln exhaust gas, the average particle size of the dust in the exhaust gas is 0.8um, the exhaust gas enters the entrance channel 201 of the spray chamber 2 after the first-stage dust removal of the cyclone separator 1; the first-stage dust removal exhaust gas fills the spray chamber 2, and is atomized The sprinkler 4 performs secondary dust removal, the spray water pressure is 140kPa, and the waste gas from the secondary dust removal flows to the outlet channel 202 through the ventilation baffle 5 . The measured dust concentration at the outlet is 317mg / m 3 . The dust removal rate is 87.2%.

[0033] Most of the water produced by atomization spraying flows into the dust collection chamber 3 throu...

Embodiment 2

[0036] Open the atomizing shower 4, the switchable partition 8 at the entrance of the dust collection chamber 3 and the switch at the outlet of the purifier 6. The dust concentration of the cyclone separator 1 inlet 101 is 3822mg / m 3 The simulated tunnel kiln exhaust gas, the average particle size of the dust in the exhaust gas is 18.0um, the exhaust gas enters the entrance channel 201 of the spray chamber 2 after passing through the cyclone separator 1 first-stage dust removal; the first-stage dust removal exhaust gas fills the spray chamber 2, and is atomized The sprinkler 4 performs secondary dust removal, the spray water pressure is 160kPa, and the waste gas from the secondary dust removal flows to the outlet channel 202 through the ventilation baffle 5 . The measured dust concentration at the outlet is 563mg / m 3 . The dust removal rate is 85.2%.

[0037] Most of the water produced by the atomization spray flows into the dust collection chamber 3 through the switchable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com