Polishing room with high dust removal rate

A technology of grinding room and dust removal rate, applied in the field of grinding room, can solve the problem of low dust removal rate, and achieve the effect of improving dust removal rate, improving air intake suction, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

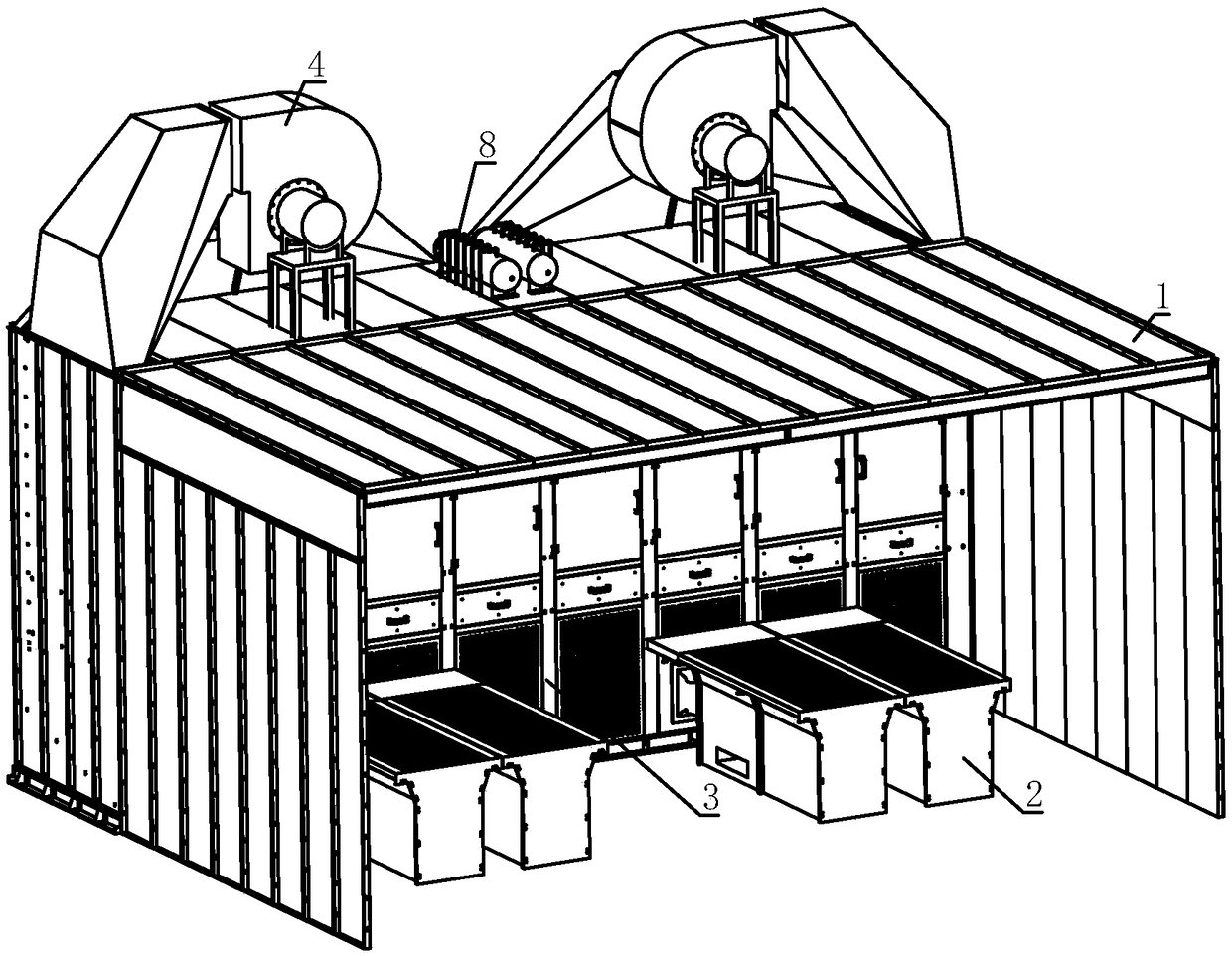

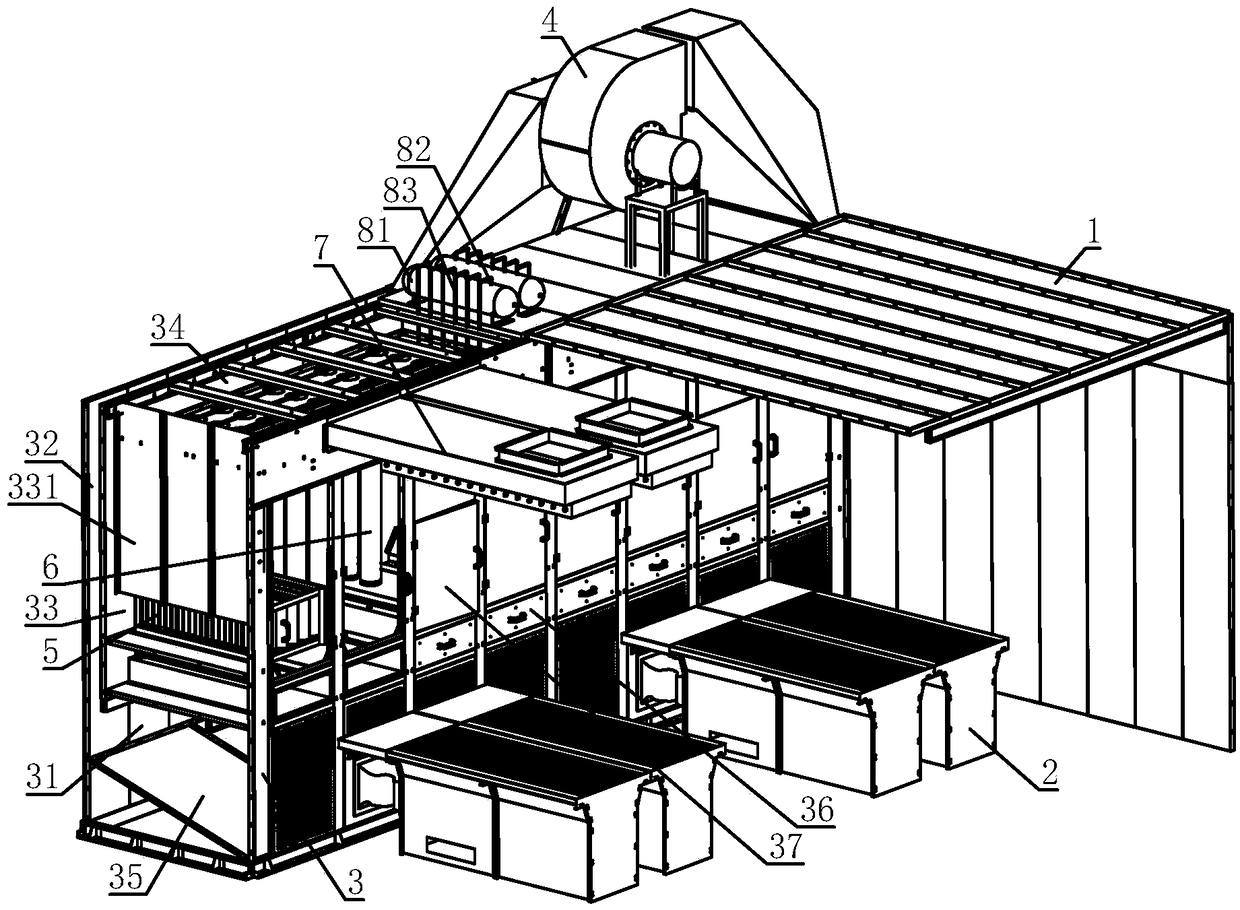

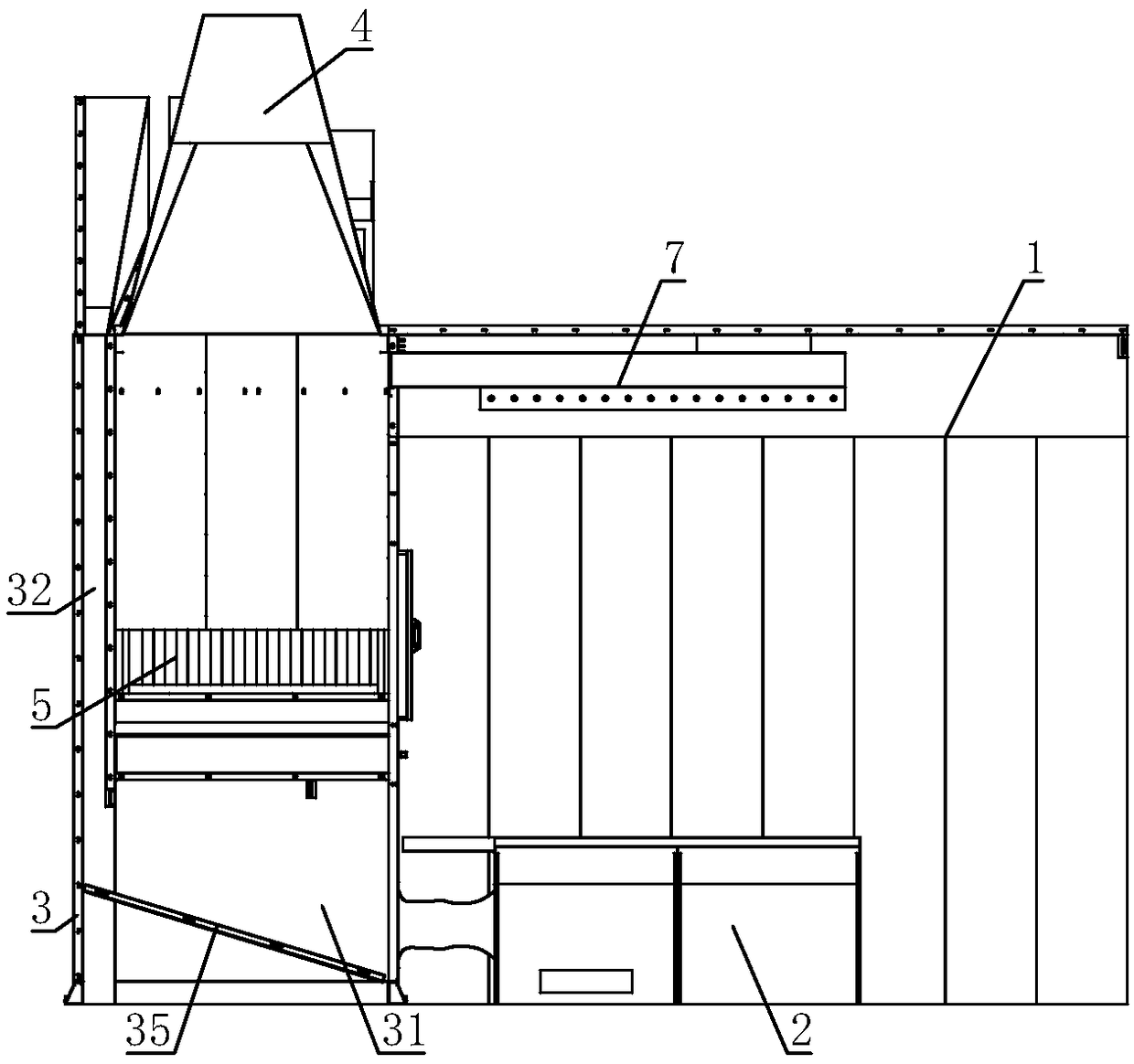

[0038] A grinding room with high dust removal rate, comprising a main body 1 of the grinding room, a grinding table 2 is installed in the main body 1 of the grinding room; a dust removal frame 3 is arranged in the main body 1 of the grinding room, and an air inlet cavity is arranged at the bottom of the dust removal frame 3 31, the air inlet cavity 31 is respectively connected with the interior of the main body of the grinding room 1 and the inner cavity of the grinding table 2, and the dust removal frame body 3 is also provided with an air inlet folder cavity 32, the air inlet cavity 31 communicates with the air inlet folder cavity 32, and the dust removal frame body 3 An exhaust fan 4 is installed on the top, and the air inlet of the exhaust fan 4 communicates with the air inlet folder chamber 32; a filter chamber 33 is arranged in the dust removal frame body 3, and the filter chamber 33 communicates with the air outlet of the exhaust fan 4, and the inside of the filter chambe...

Embodiment 2

[0043] On the basis of the first embodiment, a sloping plate 35 for partitioning and reducing the volume of the air inlet cavity is fixed inside the dust removal rack body 3 .

[0044] The setting of the sloping plate 35 further reduces the space size of the air inlet chamber 31, correspondingly increases the size of the negative pressure in the air inlet chamber 31, can further increase the inlet wind speed, and correspondingly improves the dust removal rate.

Embodiment 3

[0046] On the basis of Embodiment 1 or Embodiment 2, a dust collection drawer 36 is provided under the baffle plate 5 and the filter cloth bag 6 , and the dust collection drawer 36 is installed on the dust removal frame body 3 .

[0047] The dust falling on the baffle plate 5 and the filter cloth bag 6 can be collected by the dust collection drawer 36, so that when the exhaust fan 4 is closed, the dust collection drawer 36 can be opened to remove the dust, avoiding the need to disassemble the dust removal frame body 3 during the process. The trouble of removing dust in the wind chamber 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com