Total heat exchanger

A technology of total heat exchanger and total heat exchange, which is applied in household heating, heating methods, household heating, etc., can solve the problem of loud fan noise, large overall volume of total heat exchanger, and insufficient heat exchange efficiency of the total heat exchange core. Full play and other issues, to achieve uniform heat exchange, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

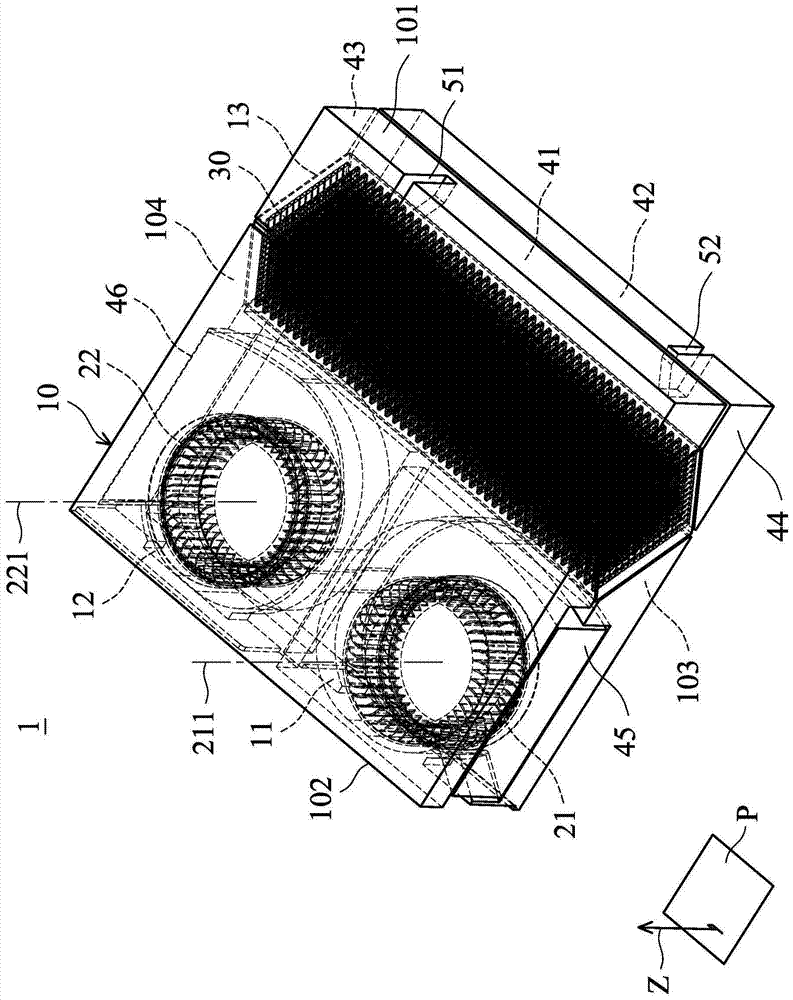

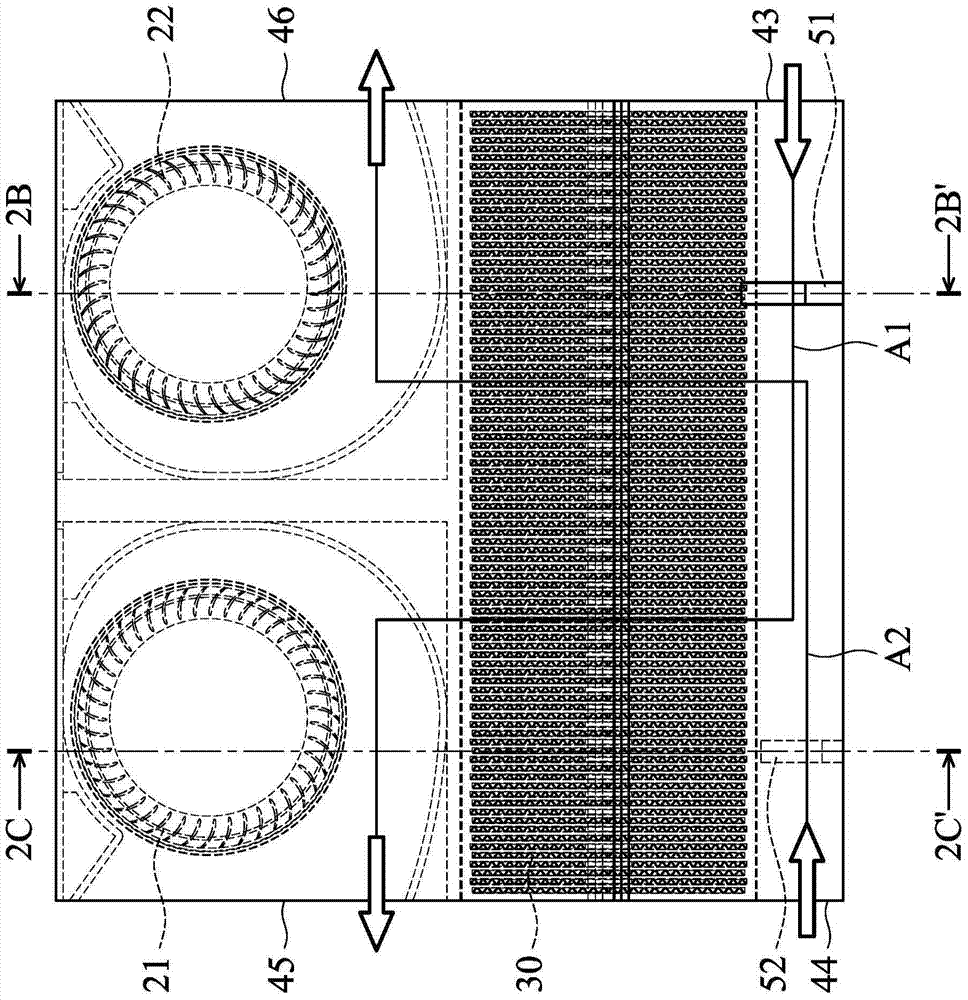

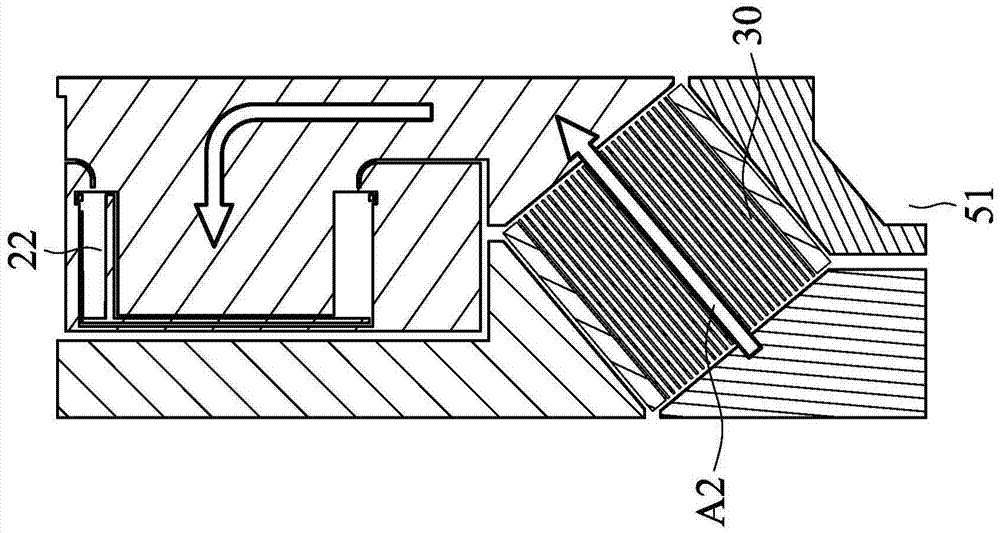

[0061] refer to figure 1 , which shows the total heat exchanger 1 of the embodiment of the present invention, including a casing 10 , a first fan 21 , a second fan 22 and a total heat exchange core 30 . The casing 10 includes a first sidewall 101 , a first accommodating space 11 , a second accommodating space 12 and a third accommodating space 13 , and the third accommodating space 13 is adjacent to the first sidewall 101 . The first fan 21 is disposed in the first accommodating space 11 and communicates with the total heat exchange core 30 . The first fan 21 includes a first rotating shaft 211 . The second fan 22 is disposed in the second accommodating space 12 and communicates with the total heat exchange core 30 . The second fan 22 includes a second rotating shaft 221 . The total heat exchange core 30 is disposed in the third accommodating space 13 . Wherein, the first fan 21, the second fan 22 and the total heat exchange core 30 are arranged on an installation plane P, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com