A combustion system based on the combination of electronically controlled electromagnet and nano-fuel

A combustion system and electromagnet technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as insignificant fuel-saving effects and elevated nitrogen oxides, improve combustion efficiency, reduce NOX emissions, and prevent air intake Caton's effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

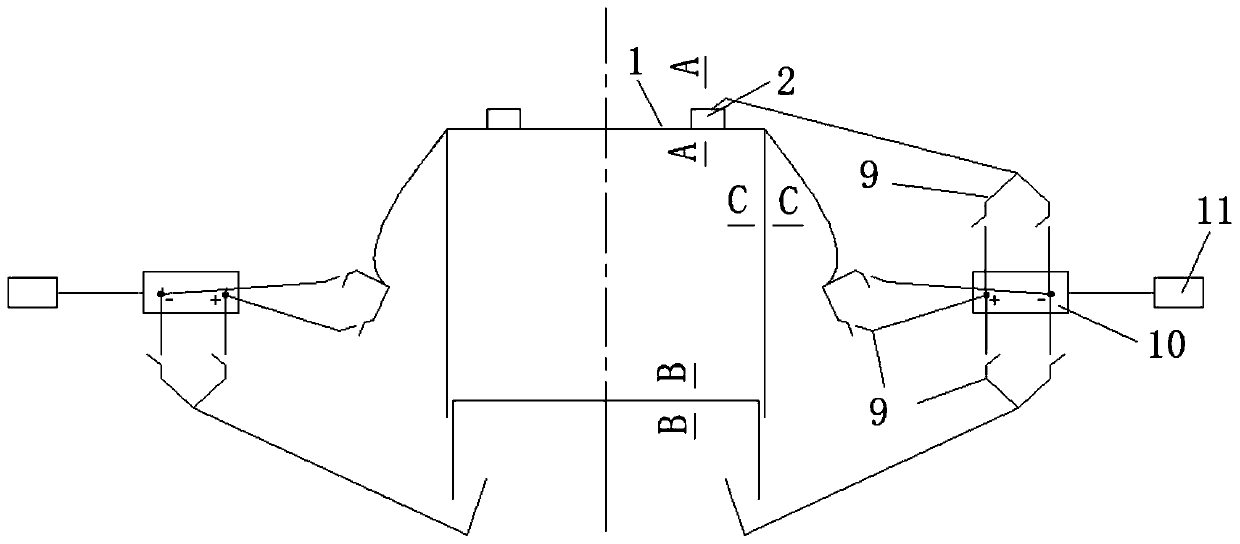

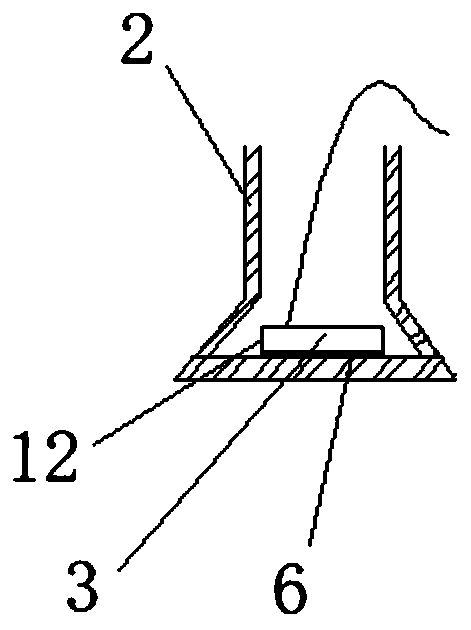

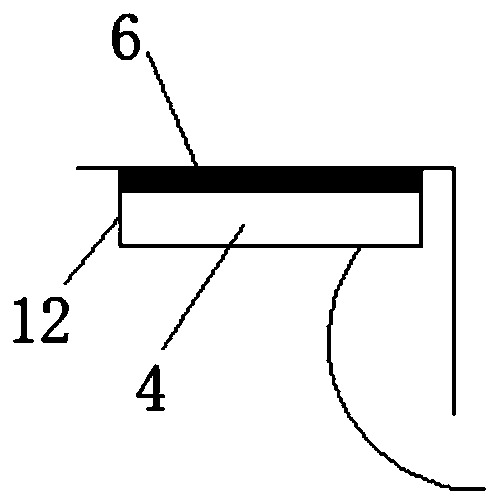

[0025] Such as figure 1 As shown, a combustion system based on the combination of electronically controlled electromagnet and nano-fuel, including cylinder 1, exhaust valve 2, first electromagnet 3, second electromagnet 4, third electromagnet 5, heat insulating block 6, Sealing case 7, water channel 8, switch 9, high voltage DC power supply 10, electronic control unit 11, holder 12; as figure 2 As shown, the exhaust valve 2 is designed to be hollow, and the first electromagnet 3 is installed through the fixer 12, and the heat insulating block 6 is fixed between the first electromagnet 3 and the exhaust valve 2, and the length of the first electromagnet 3 is 6mm; Two electromagnets 4 are symmetrically installed on the bottom of the piston by the fixer 12, such as image 3 As shown, a heat insulating block 6 is fixed between the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com