Supergravity waste gas treatment device, waste gas treatment circulating system and desulphurization and dust removal method

The technology of a waste gas treatment device and a circulation system is applied in the field of flue gas purification to achieve the effect of improving the effect of dust removal and desulfurization, improving the promotion value and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

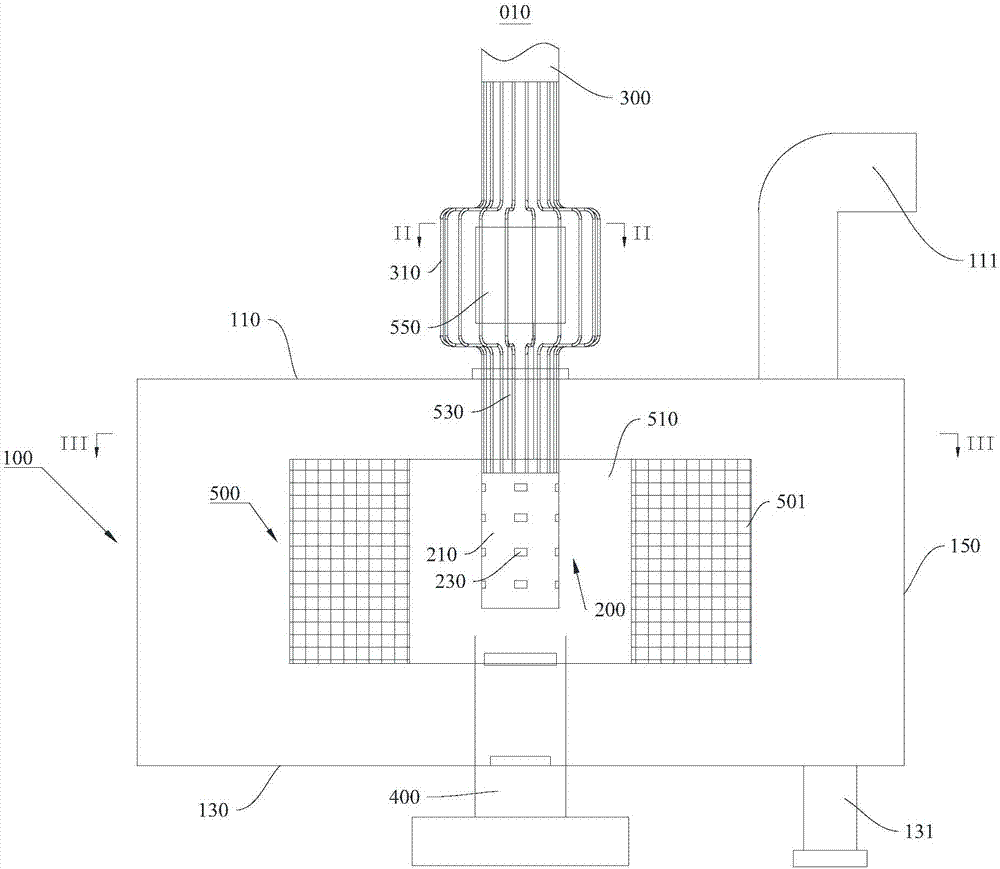

[0041] This embodiment provides a high-gravity exhaust gas treatment device, please refer to figure 1, this high-gravity waste gas treatment device includes a housing 100 , a spraying device 200 , a lye delivery pipe 300 and a waste gas pipe 400 .

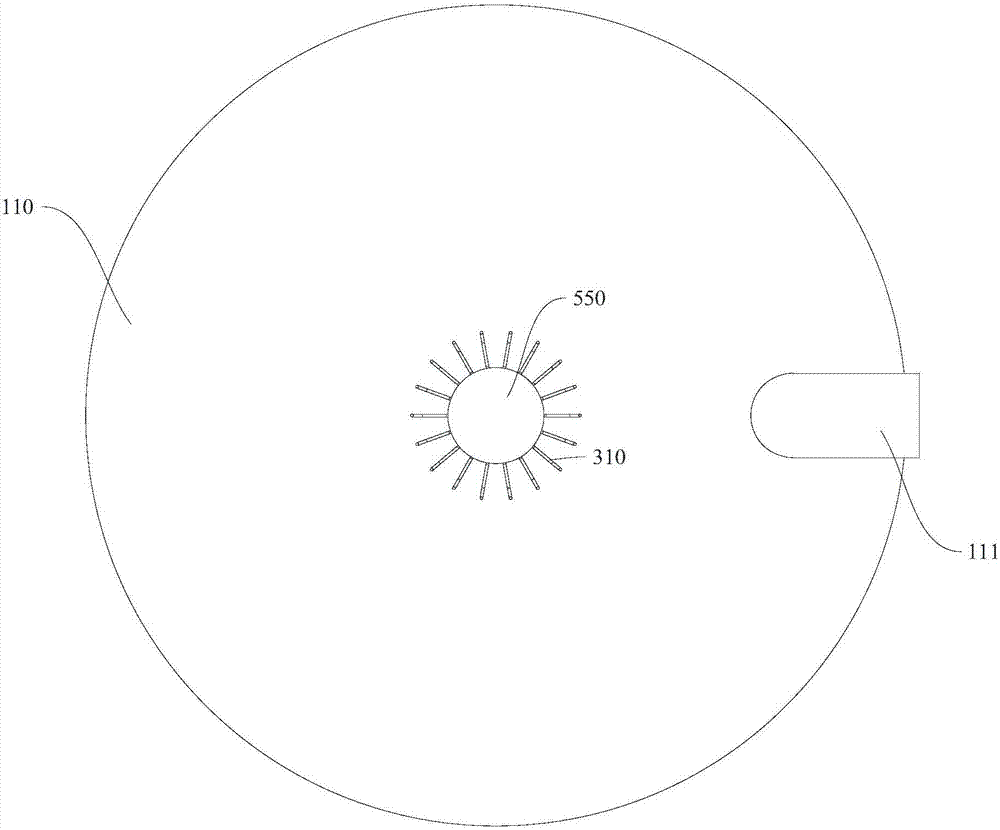

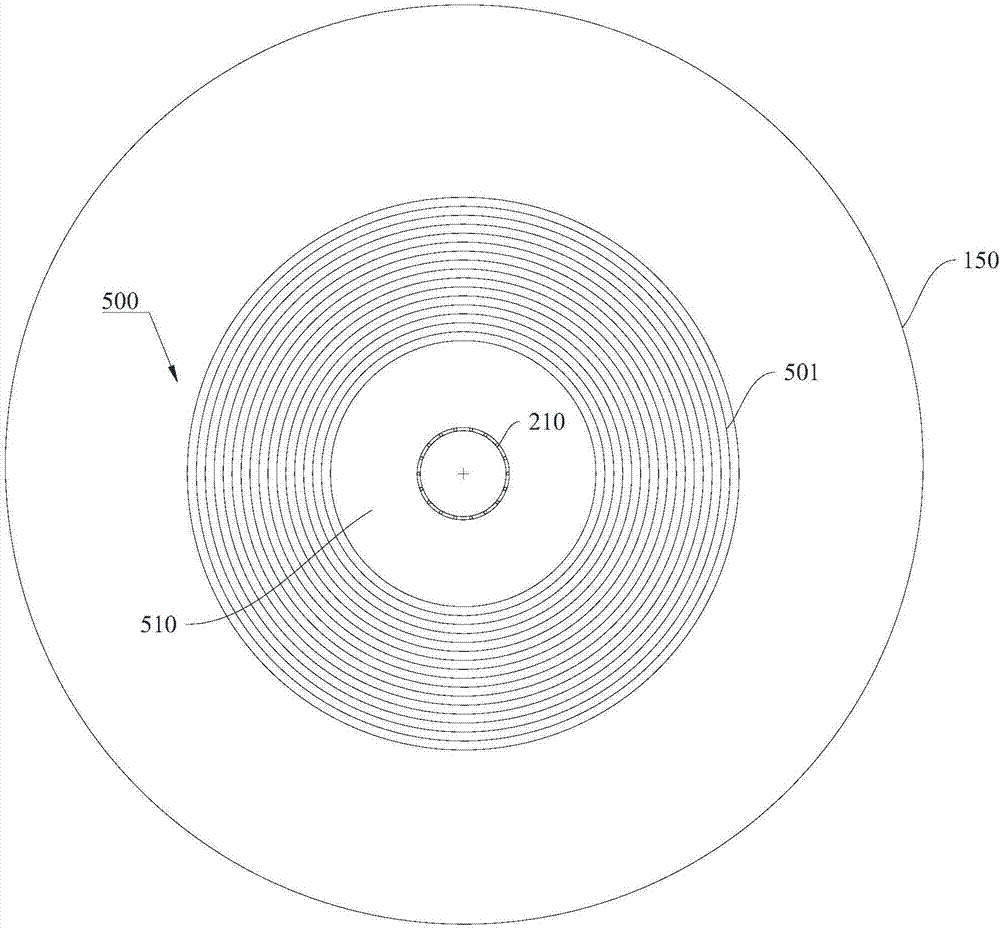

[0042] see figure 1 with figure 2 , the casing 100 is a cylindrical sealed casing, and the casing 100 includes a first surface 110 , a second surface 130 , and a side surface 150 that are oppositely arranged. The lye delivery pipe 300 passes through the center of the first surface 110 and is sealed and connected with the housing 100 , through which the lye delivery pipe 300 can deliver lye into the housing 100 . One end of the lye delivery pipe 300 close to the housing 100 is divided into a plurality of sub-pipes 310 , and the middle of the sub-pipes 310 forms a rotating accommodating space, and the rotating accommodating space can accommodate rotating components for the packing layer 500 to rotate. A lye spraying device 200 is...

Embodiment 2

[0051] This embodiment provides a waste gas treatment circulation system 001, please refer to Figure 4 , this exhaust gas treatment circulation system 001 includes a lye circulation unit 020 and the high-gravity exhaust gas treatment device in Embodiment 1.

[0052] The lye used in this embodiment is NaOH solution. The desulfurization reaction of lye in the supergravity waste gas treatment device is as follows:

[0053] 2NaOH+SO 2 →Na 2 SO 3 +H 2 o

[0054] Na 2 SO 3 +SO 2 +H 2 O→2NaHSO 3

[0055] After the lye is desulfurized, it forms a large amount of Na 2 SO 3 and NaHSO 3 The waste lye, and the waste lye can be reused through the lye circulation unit 020, and the lye is formed after reuse for the desulfurization and dust removal of the supergravity waste gas treatment device.

[0056] The lye circulation unit 020 includes a regeneration pool 021 , which is connected to the supergravity waste gas treatment device and can accept the waste lye discharged from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com