Comprehensive treatment system and method for three wastes of copper-containing industrial sludge

A technology for comprehensive treatment of industrial sludge, applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., to reduce manpower burden and improve smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

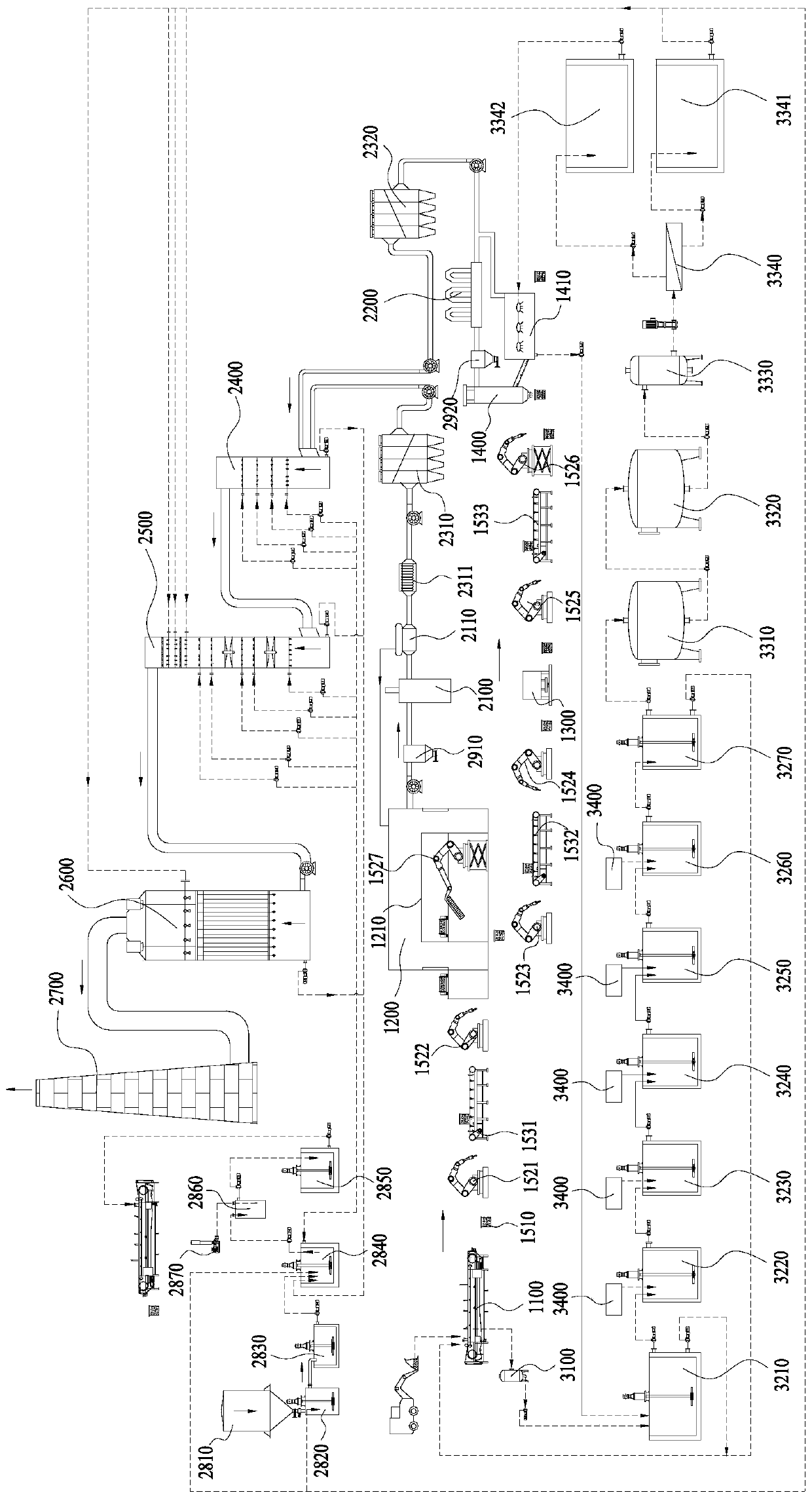

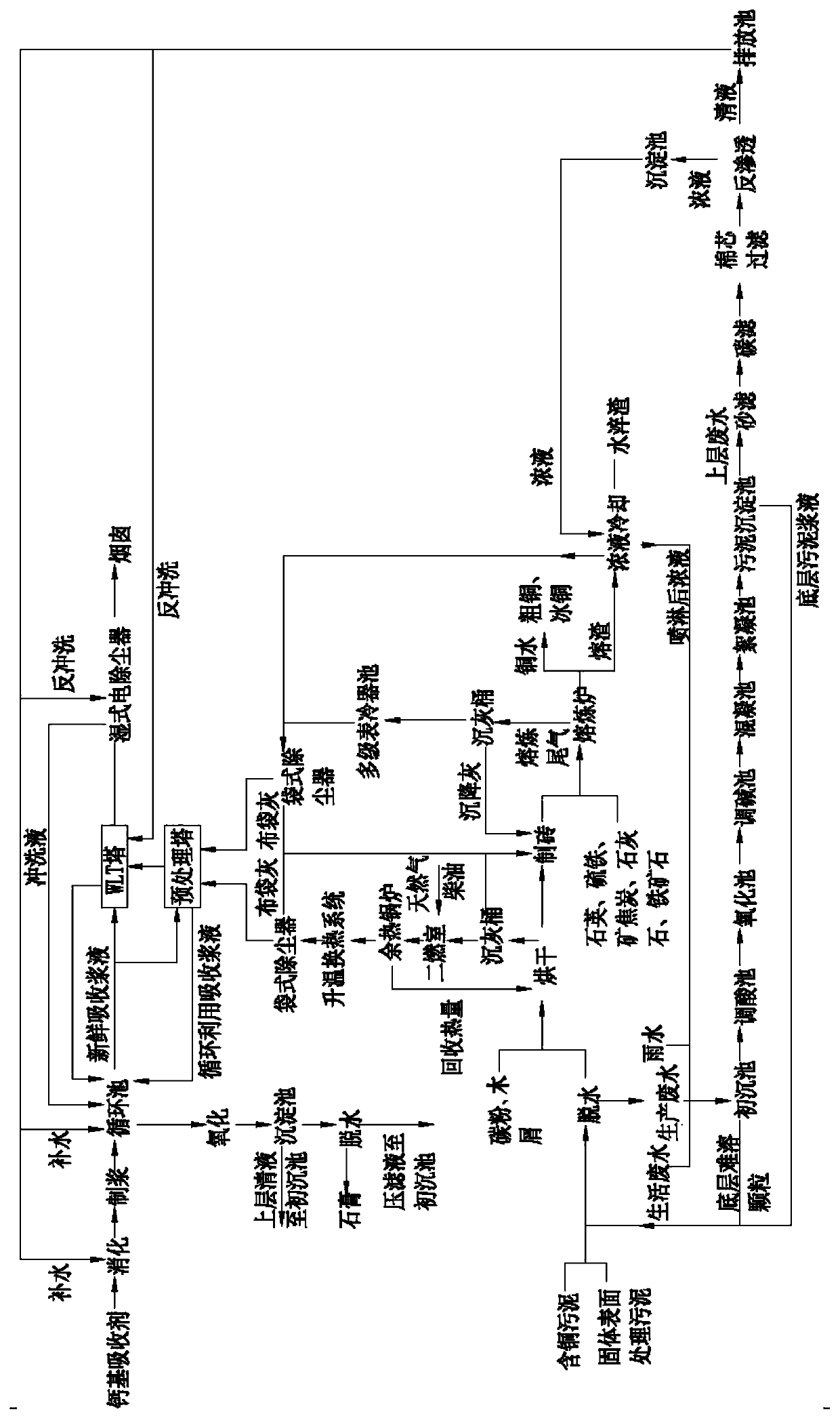

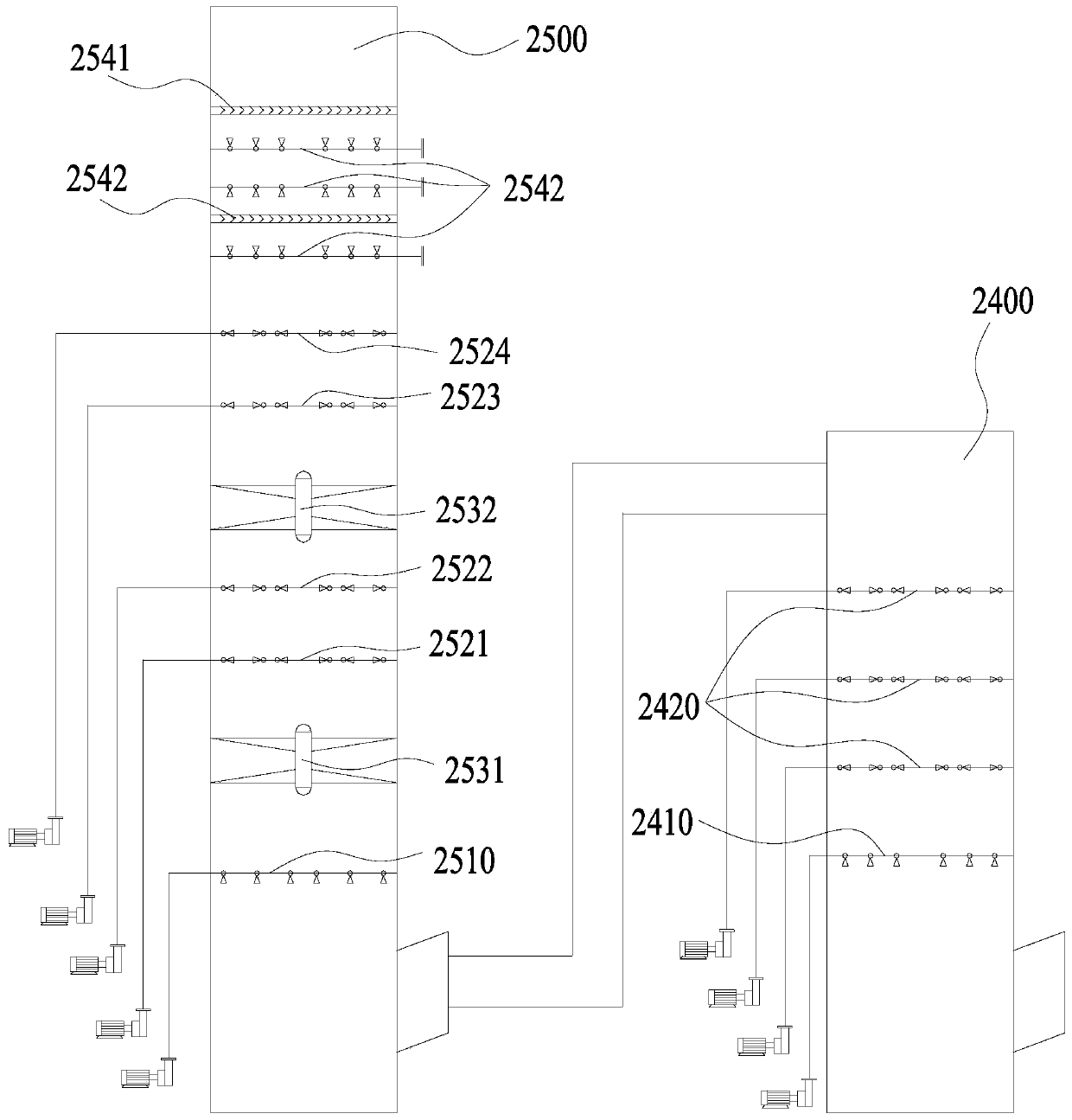

[0105] A method for comprehensive treatment of copper-containing industrial sludge three wastes, using the treatment equipment of the present invention, such as figure 1 As shown, it includes three modules: solid waste treatment equipment, waste gas treatment equipment and sewage treatment equipment; the above treatment methods are as follows figure 2 As shown, it includes three major processes: solid waste treatment process, exhaust gas treatment process and sewage treatment process; the specific description is as follows.

[0106] 1. Solid waste treatment.

[0107] The solid waste treatment equipment includes a filter press 1100, a drying assembly 1200, a brick making machine 1300, and a melting furnace 1400. The filter press, drying assembly, brick making machine, and melting furnace are arranged in sequence according to the process flow.

[0108] The solid waste treatment equipment in this embodiment also includes an automatic feeding system, which includes a movable col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com