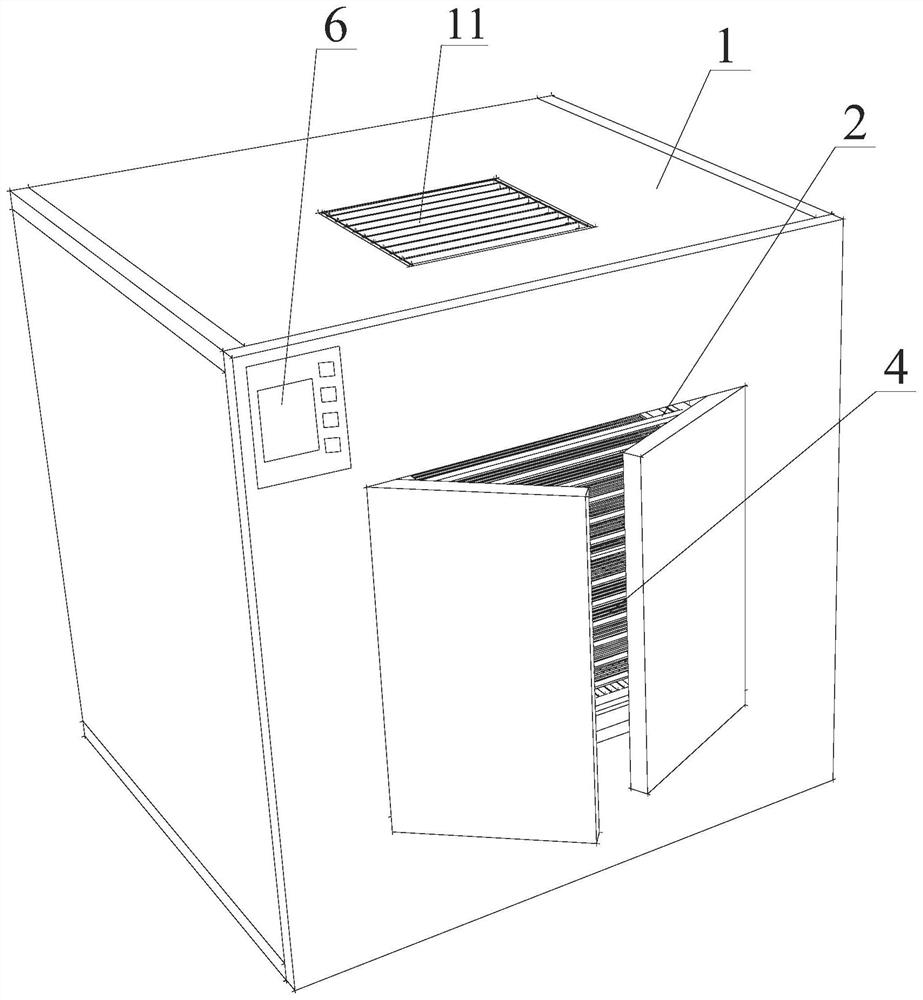

Tremella drying process and tremella drying device

A drying process and drying device technology, applied in drying gas arrangement, heating device, drying of solid materials, etc., can solve the problems of inability to adjust the air volume in the drying process, poor quality of Tremella fungus, inaccurate timing control, etc. The effect of drying, high efficiency and energy saving, good shaping, and optimizing the shape of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

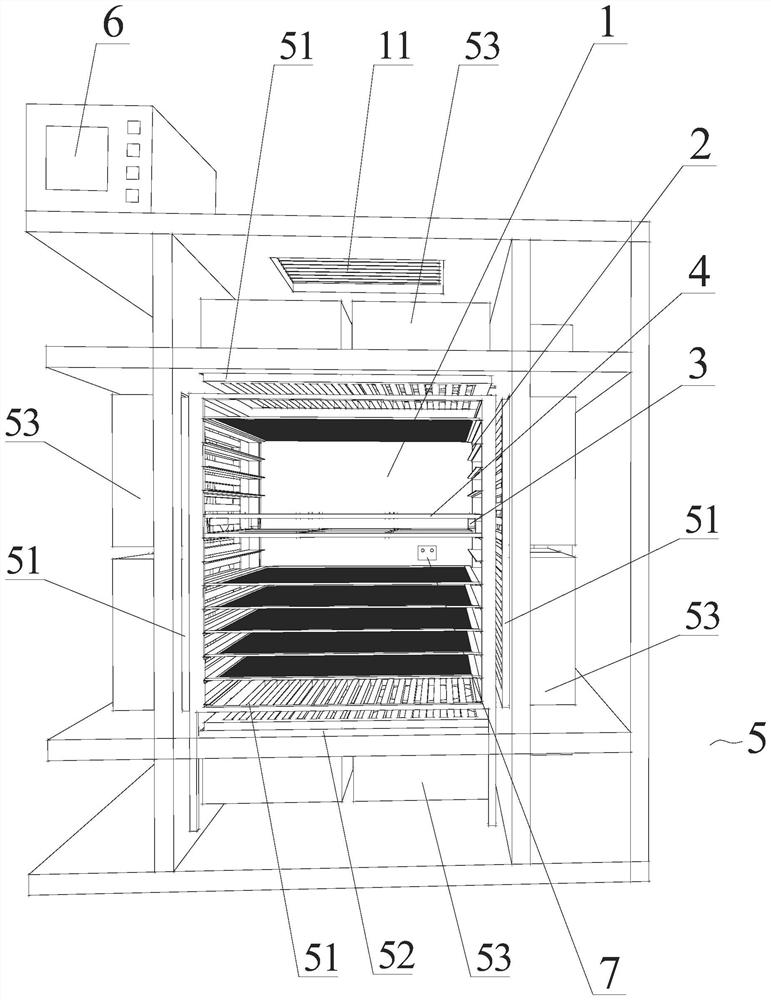

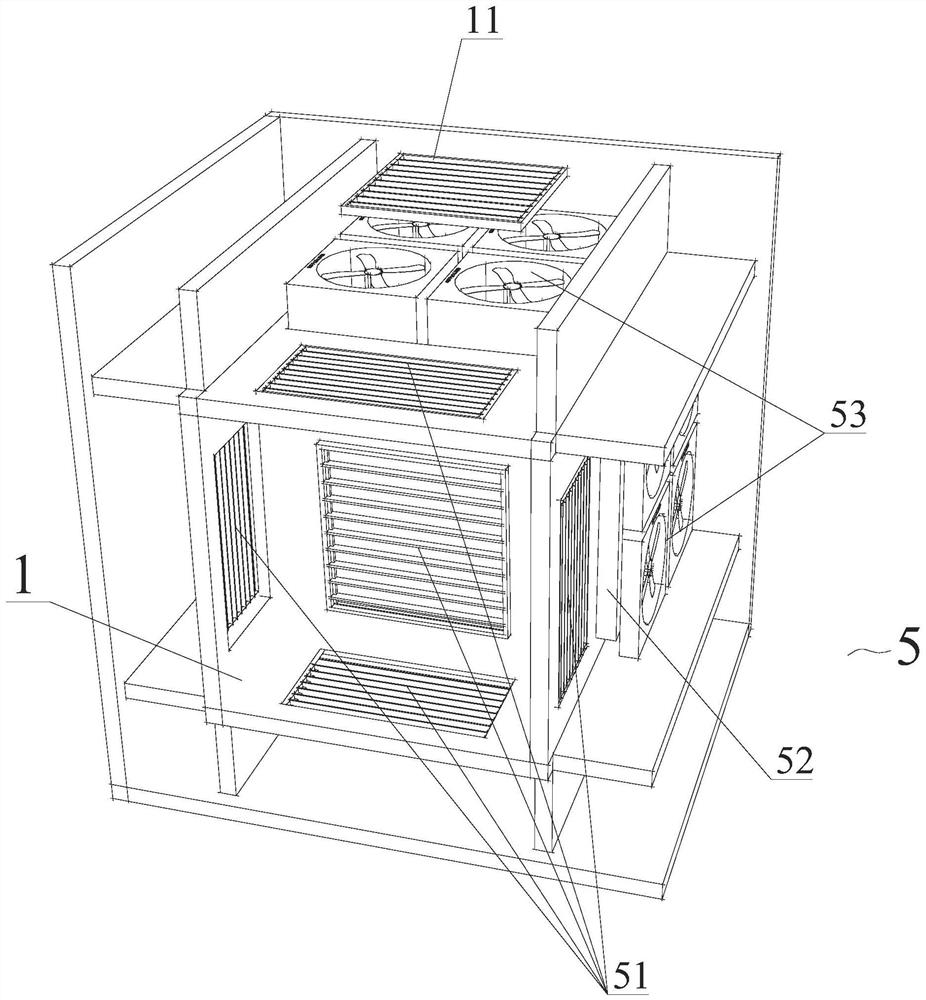

[0044] Example 1: The moisture outlet 11, the top, rear and bottom electric louvers 51 are opened, the top axial flow fan 53 is turned on for reverse rotation, the bottom axial flow fan 53 is turned on for forward rotation, the bottom electric auxiliary heating plate 52 is energized, and the external air passes through the bottom The electric louvers 51 enter, generate hot air through the electric auxiliary heating plate 52 at the bottom, and blow it into the drying room 1 through the bottom axial flow fan 53 to exchange heat and humidity with the material, then pass through the top axial flow fan 53, the top electric louver 51 and the moisture outlet 11 It is discharged out of the drying room 1 to form a convective dehumidification of the downwind; the main purpose of this process is to strengthen the dehumidification during drying.

example 2

[0045] Example 2: The top and bottom electric louvers 51 are opened, the top axial flow fan 53 is turned on for forward rotation, the bottom axial flow fan 53 is turned on for reverse rotation, the top electric auxiliary heating plate 52 is energized, the air enters through the top electric louvers 51, and passes through the top electric auxiliary heating The plate 52 generates hot air, which is blown by the top axial fan 53 into the hot air and brought into the drying room 1 to exchange heat and humidity with the material, and then continue to circulate through the bottom axial fan 53 and the bottom electric shutter 51; the top axial fan can be adjusted as required 53 and the forward and reverse direction of the bottom axial flow fan 53, and connecting the corresponding electric auxiliary heating plate 52, so as to form a convective internal circulation of upwind or downwind. The main purpose of this process is to heat quickly during drying.

example 3

[0046] Example 3: The left electric louver 51 and the right electric louver 51 are opened, the right axial flow fan 53 is turned on and rotates forward, the left axial flow fan 53 is turned on and reversed, the right electric auxiliary heating plate 52 is energized, and the air passes through the right electric The shutter 51 enters, generates hot air through the electric auxiliary heating plate 52 on the right side, blows it into the hot air through the axial flow fan 53 on the right side, and brings it into the drying room 1 to exchange heat and humidity with the material. 53 to continue the circulation, as required, the reverse direction of the left and right axial flow fans 53 can be adjusted, and the corresponding electric auxiliary heating plate 52 can be connected to form a convective internal circulation of the left and right wind or the right and left wind; the bottom can also be opened at the same time Axial flow fan 53 and electric shutter 51 at the bottom realize in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com