A drying process for paper and cardboard

A drying process and insulating cardboard technology, which is applied in the direction of dryers, papermaking, paper machines, etc., can solve the problems of affecting the appearance quality of products, affecting the internal quality of products, and uneven drying of products, so as to achieve uniform and stable drying, improve internal quality, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

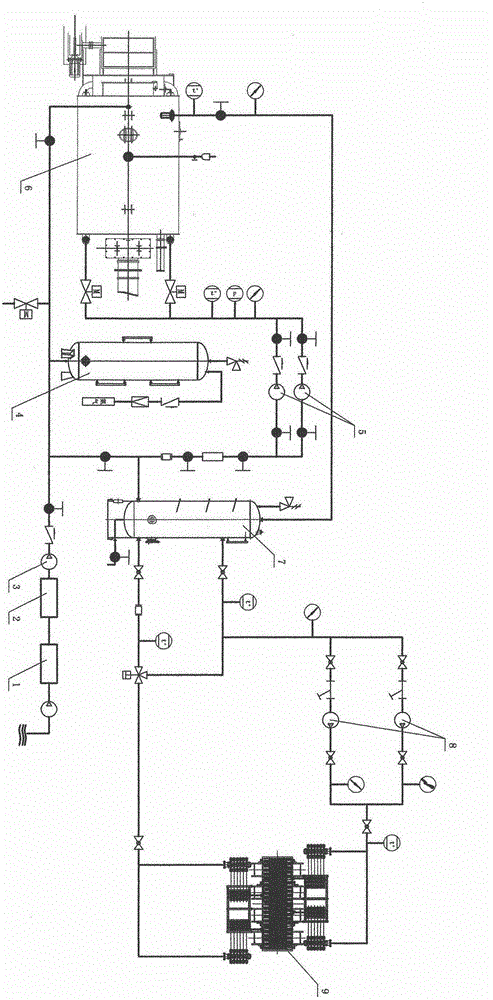

Image

Examples

Embodiment Construction

[0019] The water used for ultra-high voltage insulating paperboard production is to pretreat water (river water, mine water, lake water or ground water) through the integrated device 1, and then pass through the reverse osmosis device 2, so that the hardness of the water is less than 0.03m mol / L, and the conductivity becomes smaller. 4~6μs / M; the soft water used in the pressurized hot water system is directly taken from the production water, and sent to the special boiler 6 (pressurized hot water boiler) and high temperature tower 7 by the boiler water pump 5; the pressurized hot water boiler 6 and Other steam boilers are basically similar, their bearing pressure is greater than 2.5MPa, there is a safety valve and two automatic exhaust valves on the furnace top, but there is no liquid level gauge, and the pressurized hot water boiler must be full of water to run. Generally, boilers take water from the top, and pressurized hot water boilers such as figure 1 As shown, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com