Automatic spraying production line of automobile lamp PC mask hardening paint

An automatic spraying and production line technology, which is applied to the surface coating liquid device, coating, spray booth, etc., can solve the problems of unfavorable ultraviolet drying, large human injury, high energy consumption, etc., to ensure the filtering effect and heat drying Effect, reduce safety hazards, improve the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and specific embodiments.

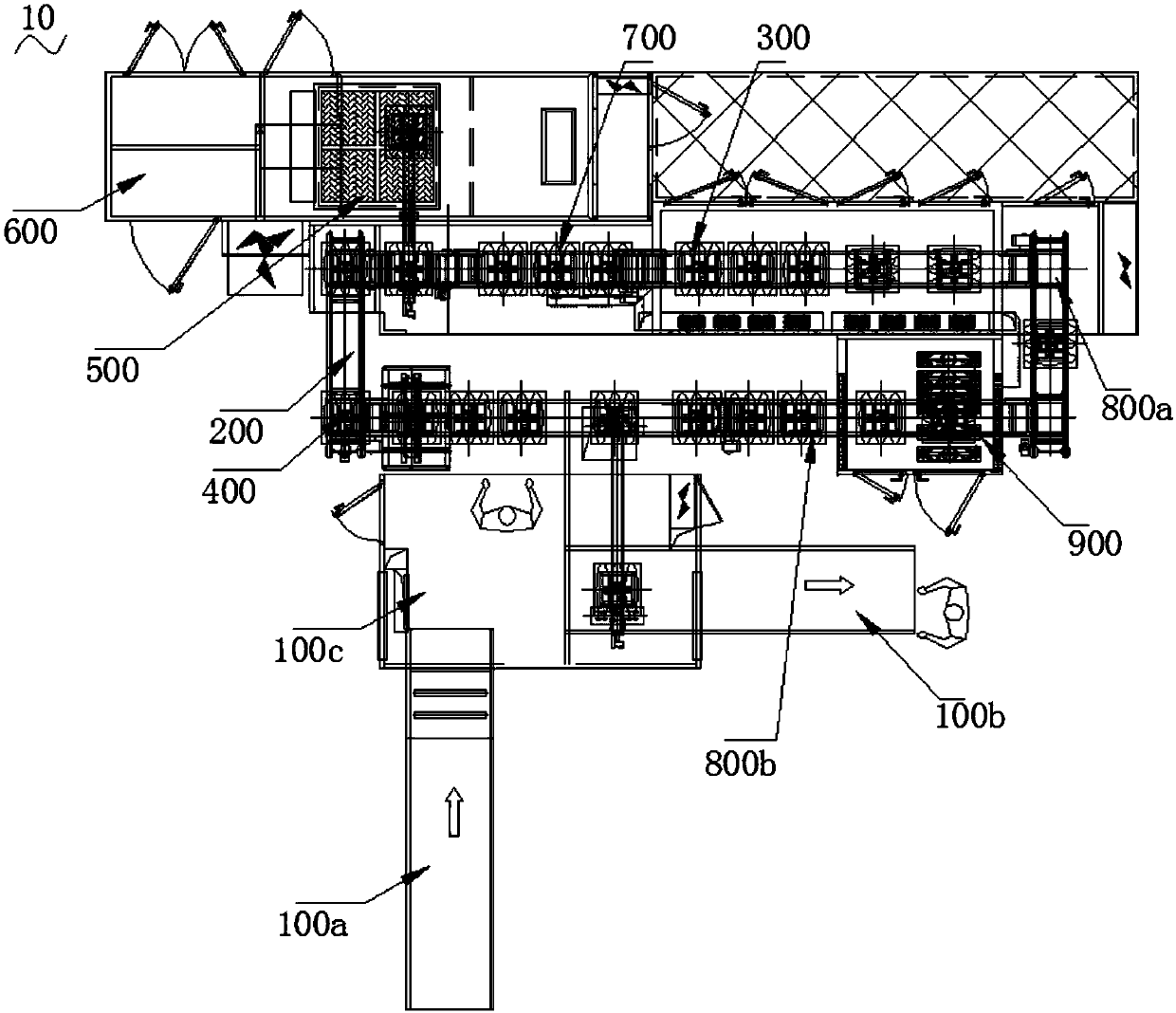

[0046] Such as figure 1 Shown is a schematic diagram of the structure of the present invention.

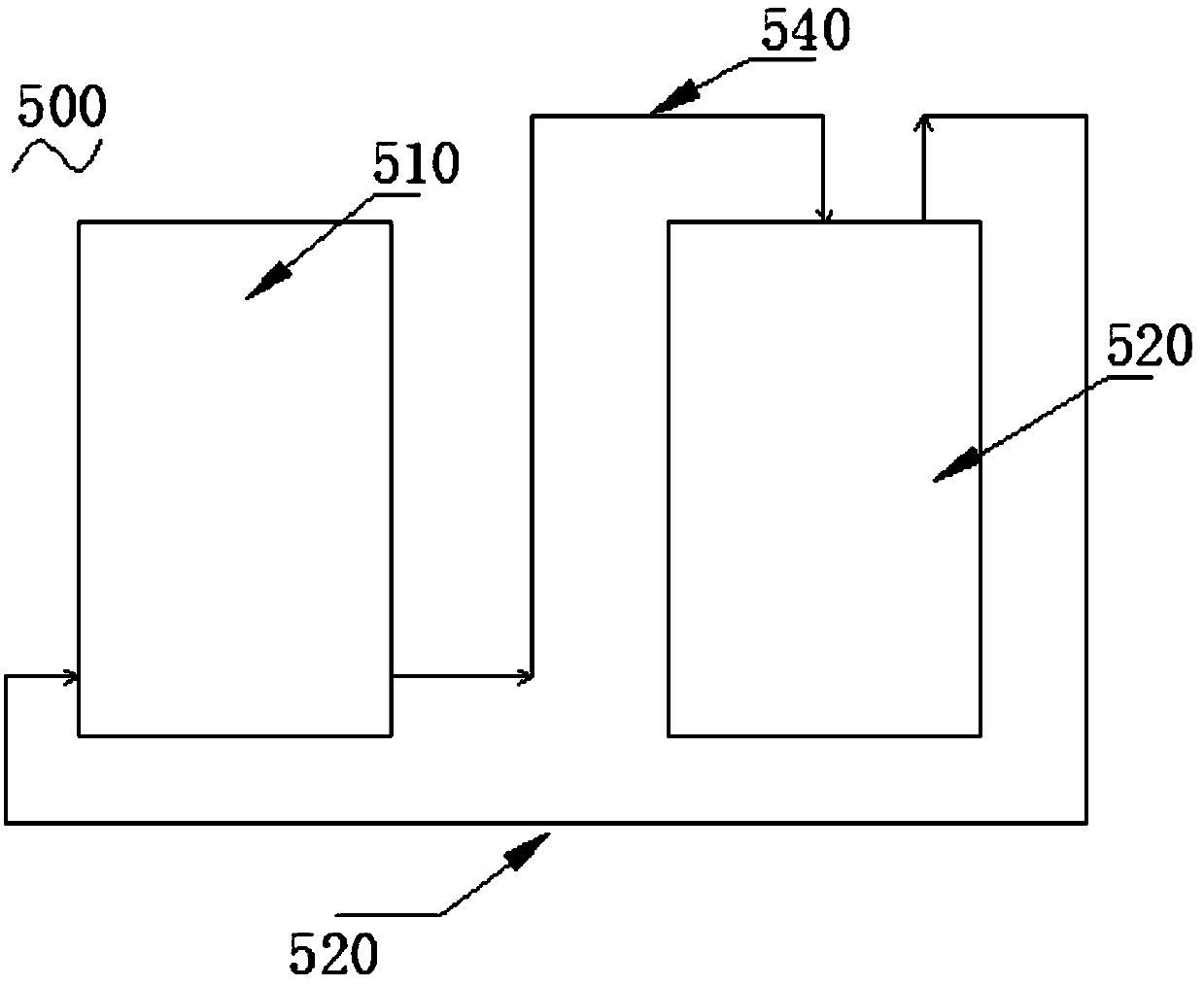

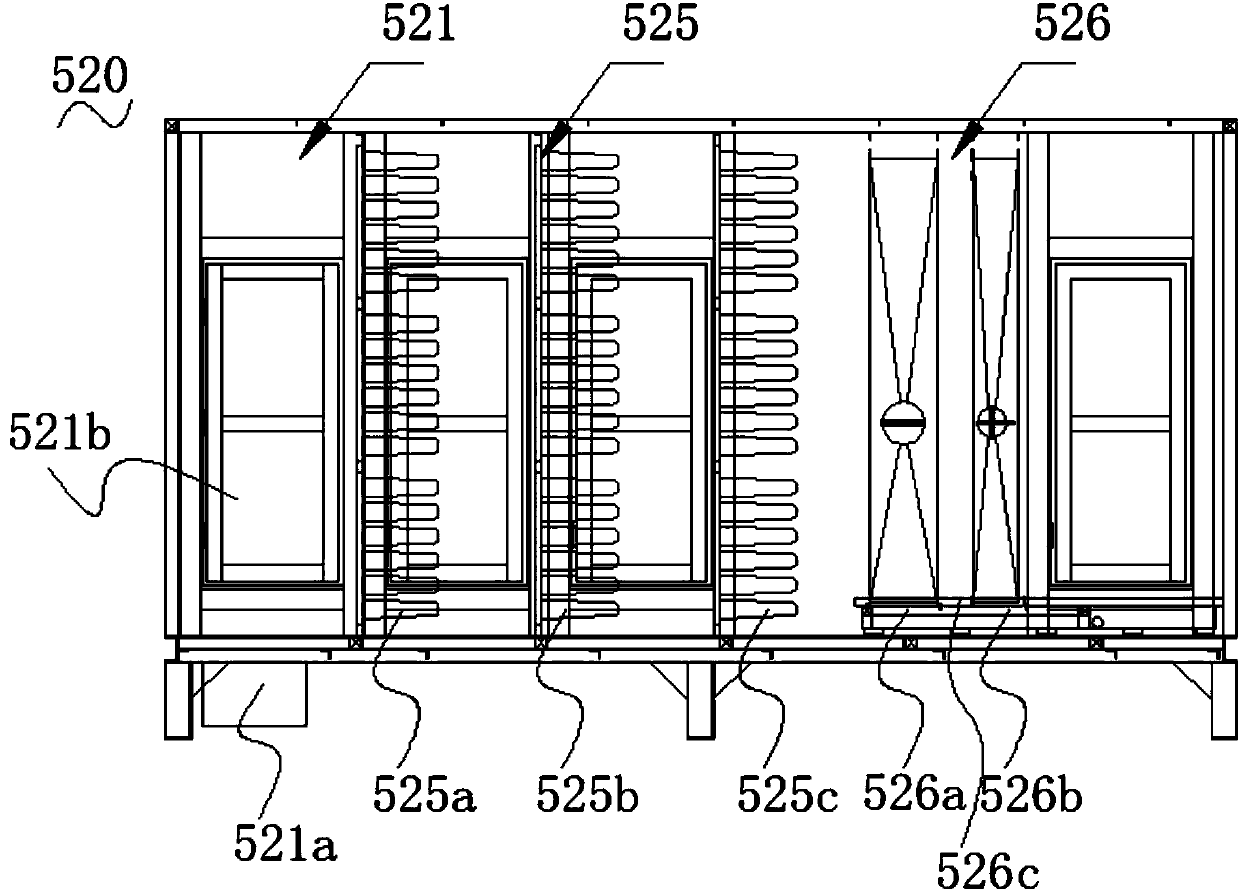

[0047] Auto lamp PC face mask hardening paint spraying production line 10, including upper part conveyor belt 100a, clean room 100c at the end of upper part conveyor belt 100a, dust removal station 400 on the side of clean room 100c, and painting station connected to dust removal station 400 500. The paint supply station 600 connected to the side of the spraying station 500, the leveling station 700 connected to the spraying station 500 on the side away from the paint supply station 600, and the infrared drying station set on the side of the leveling station 700 300. The first cooling station 800a connected to the infrared drying station 300, the ultraviolet drying station 900 connected to the side of the first cooling station 800a, and the second cooling station 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com