Liquid alkali decomposition method of high-grade mixed rare earth ore concentrate

A mixed rare earth, high-grade technology, applied in the direction of chemical instruments and methods, phosphorus compounds, process efficiency improvement, etc., can solve the problems of shortened process flow, short reaction time, high reaction temperature, etc., to achieve good fluidity of the system and long reaction time The effect of short and small change of alkali concentration in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

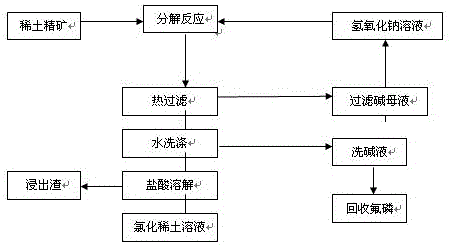

Image

Examples

Embodiment 1

[0017] Take 500g of sodium hydroxide to make a 65wt% solution, add 100g of mixed rare earth ore (REO 65wt%), heat it to 150°C in the reactor after mixing, keep it warm for the reaction, stop the reaction, cool down to the temperature of 110°C, filter while it is hot, and then Rinse with a small amount of hot water to ensure that the temperature of the system after filtration is greater than 80°C. The filtrate was recycled after adding consumed sodium hydroxide and water, and 100g of mixed rare earth ore (REO 65wt%) was added for the second test. Wash the alkali cake to neutrality, measure the decomposition rate of rare earth minerals, and then dissolve it with 9M hydrochloric acid, and control the pH of the solution to 4~5 to obtain a rare earth chloride solution. The results of the 5-cycle test are shown in Table 1.

[0018] .

Embodiment 2

[0020] Take 400g of sodium hydroxide to make a 65wt% solution, add 100g of mixed rare earth ore (REO 65wt%), heat it in a beaker to 150°C after mixing, keep it warm for reaction, then stop the reaction and cool down to 110°C, filter while it is hot, and then use Rinse with a small amount of hot water to ensure that the temperature of the system after filtration is greater than 80°C. The filtrate was recycled after adding consumed sodium hydroxide and water, and 100g of mixed rare earth ore (REO 65wt%) was added for the second test. Wash the alkali cake with water to neutrality, measure the decomposition rate of rare earth minerals, and then dissolve it with 10M hydrochloric acid, and control the pH of the solution to 4~5 to obtain a rare earth chloride solution.

[0021] The results of the 3 cycle tests are shown in Table 2:

[0022] Cycles 1 2 3 Response time (min) 20 30 40 Decomposition rate (%) 97.5 98.6 99.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com