Fine dust particle convergent resonant cavity based on multiple sensors

A multi-sensor and resonant cavity technology, applied in chemical instruments and methods, solid separation, electrostatic separation, etc., can solve the problems that it is impossible to provide converging electrode plates, and achieve the effect of improving the converging effect, increasing the residence time and improving the dust removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

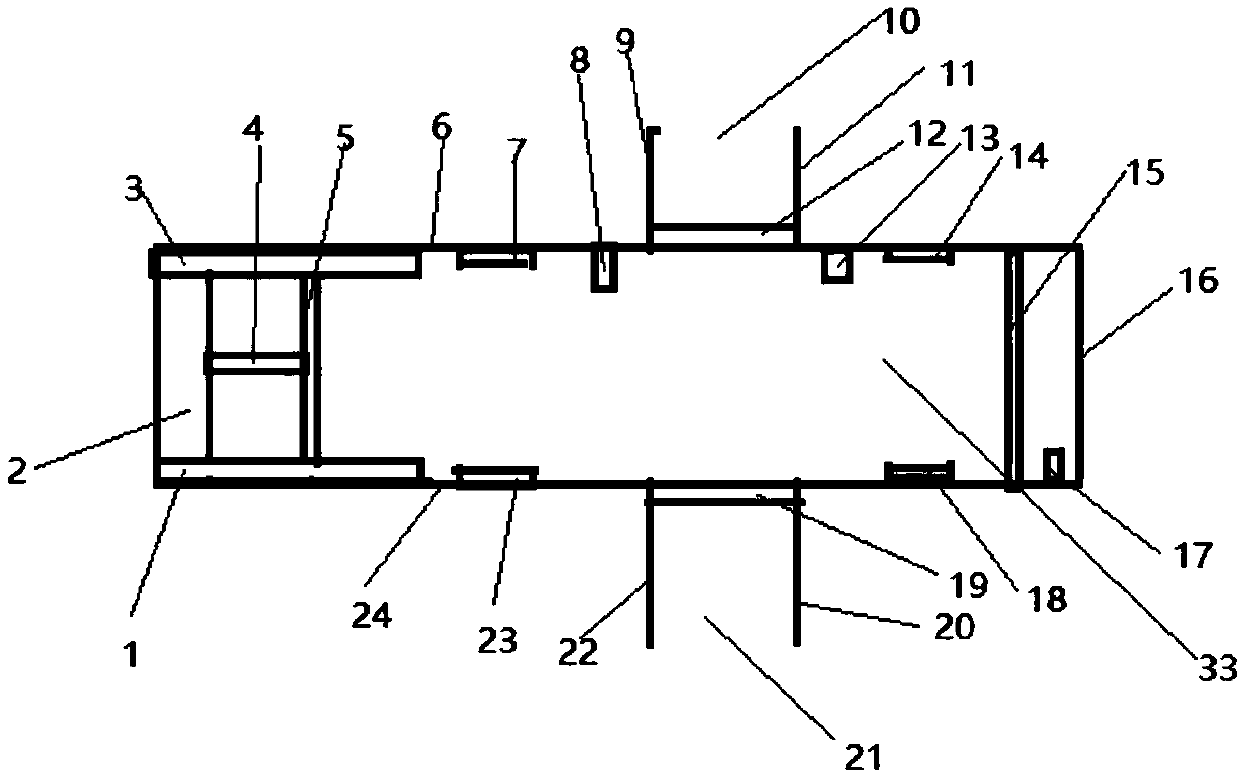

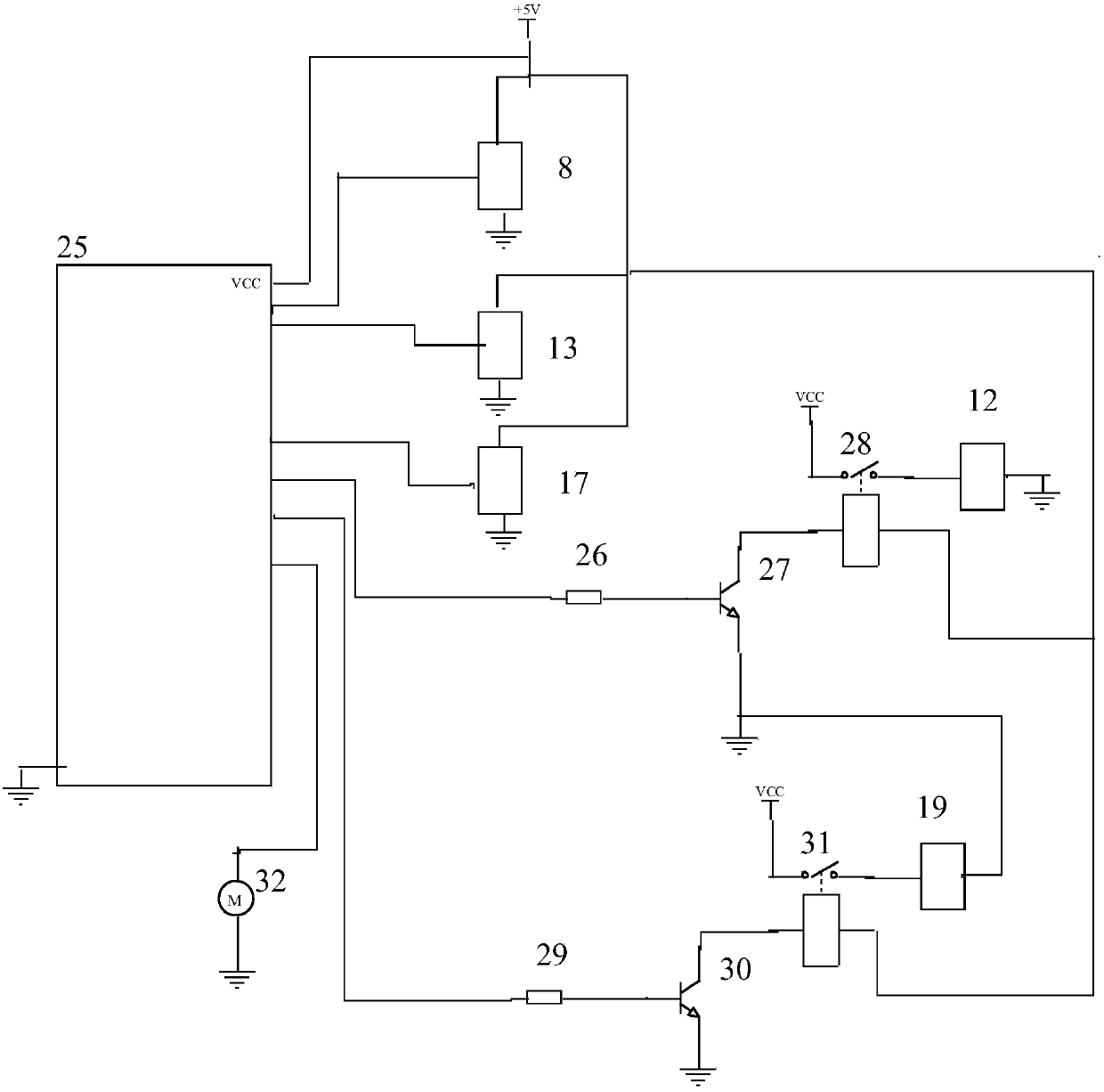

[0011] exist figure 1 Among them, the glideway 1 is connected with the lower cavity wall 24, the tractor 2 is connected with the glideway 1, the upper slideway 3 is connected with the tractor 2, the push-pull rod 4 is connected with the tractor 2, and the pressure plate 5 is connected with the push-pull rod 4, The upper slideway 3 is connected with the upper chamber wall 6, the left positive converging electrode plate 7 is connected with the upper chamber wall 6, the upper pressure sensor 8 is connected with the upper chamber wall 6, the left wall 9 of the branched flue is connected with the upper chamber wall 6, and the branched flue is right The wall 11 is connected with the upper chamber wall 6, the filter cloth 15 is connected with the upper chamber wall 6, the particle distribution sensor 13 is connected with the upper chamber wall 6, the right negative converging electrode plate 14 is connected with the upper chamber wall 6, the right chamber wall 16 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com