Electric dust remover with inlet airflow distribution plate

A technology of airflow distribution plate and electrostatic precipitator, which is applied in steam flow control, external electrostatic separator, solid separation, etc., can solve problems such as affecting the physical and mental health of operators, wasting energy, and obsolete dust removal effect of dust removal equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

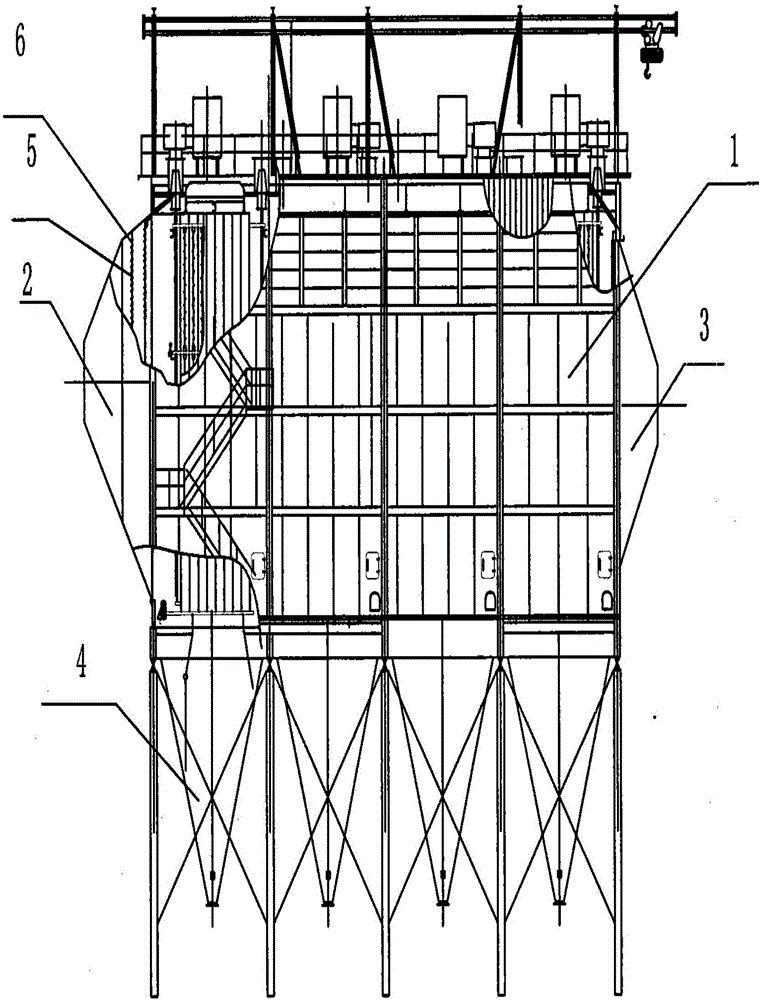

[0012] Example: such as figure 1 As shown, an electrostatic precipitator with an inlet airflow distribution plate includes a casing 1, one end of the casing 1 is an airflow inlet 2, the other end of the casing 1 is an airflow outlet 3, and the bottom of the casing 1 is provided with an outlet The ash hopper 4, the airflow inlet 2 is provided with an inlet airflow distribution plate 5, the inlet airflow distribution plate 5 is provided with a guide layer 6 evenly distributed, and the airflow inlet 2 is arranged at the head of the housing 1 part, the inlet air distribution plate 5 is arranged on the head of the housing 1, the guide layer 6 is inclined, and the head of the housing 1 is provided with two layers of inlet air distribution plate 5, the inlet The air flow distribution plate 5 is distributed in the housing 1 in a trapezoidal shape, and the inlet air distribution plate 5 is matched and fixed with the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com