Intelligent dust removal system for spinning workshop

A technology of dust removal system and intelligent spinning, which is applied in the fields of removing smoke and dust, air conditioning systems, textiles and papermaking, etc., can solve the problems of high dust removal power consumption, easy slipping of workers, human health hazards, etc., to improve the dust removal rate and dust removal efficiency. , The effect of improving the utilization rate of raw materials and reducing the dust content of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

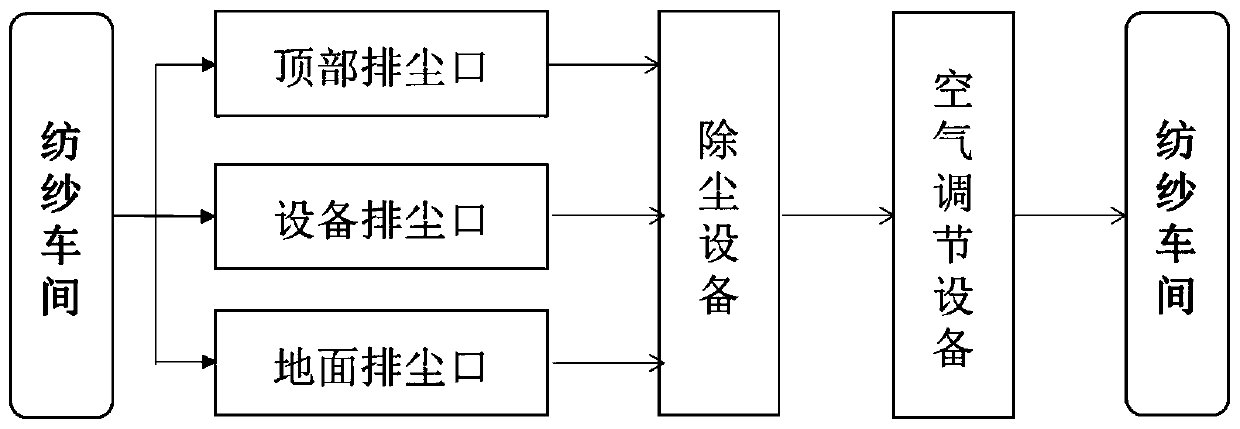

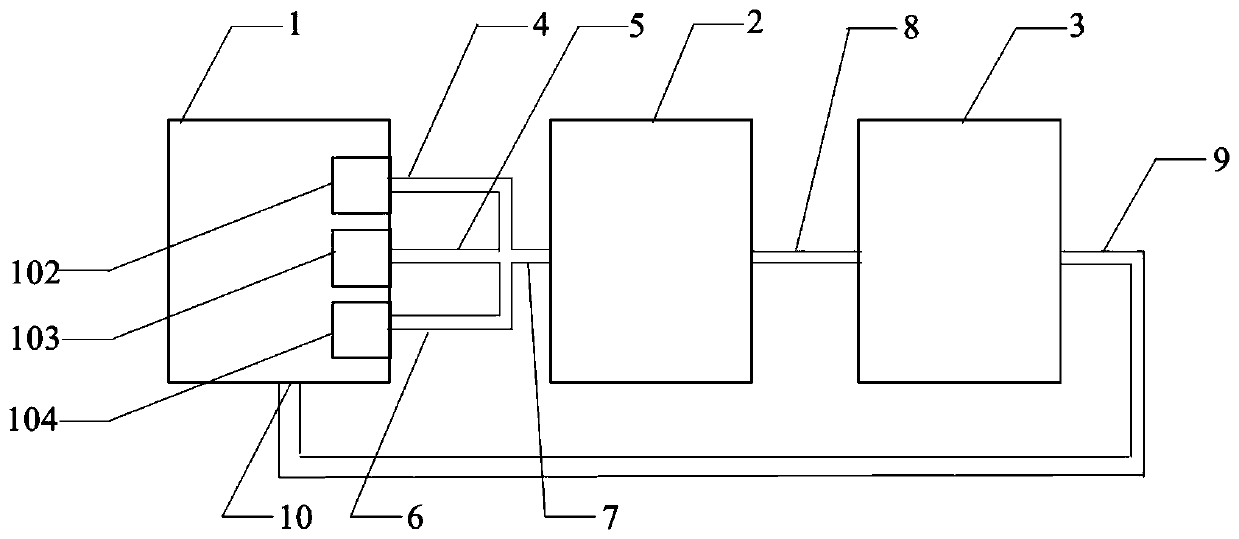

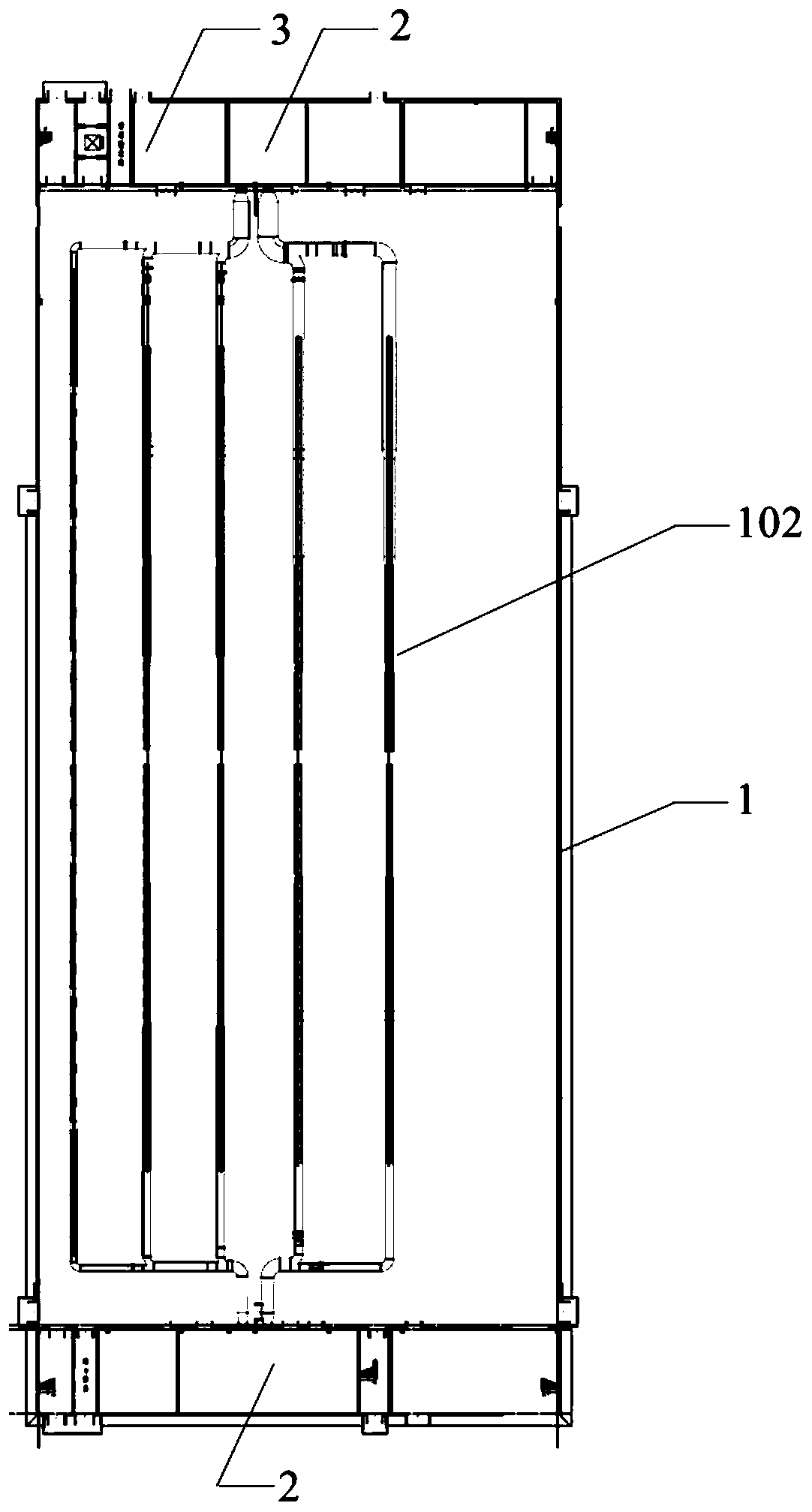

[0041] An intelligent spinning workshop dust removal system, such as Figure 1-5 As shown, it includes a spinning workshop 1, a dust removal room 2 and an air-conditioning room 3. The spinning workshop 1 includes a spinning equipment area and a pedestrian aisle area. The pedestrian aisle area is evenly distributed with ground dust outlets 101. Below the ground dust outlet It is an underground dust collection pipeline 102, and the top of the workshop is equipped with a top dust outlet 104, and the spinning equipment is provided with an equipment dust outlet 103; The fan is connected to blow air into the spinning workshop 1; the underground dust collection pipe 102, the equipment dust discharge port 103 and the top dust discharge port 104 are connected with the first dust discharge pipe 4, the second dust discharge pipe 5 and the third dust discharge pipe respectively. The pipes 6 are connected, and the three groups of dust discharge pipes are connected with the dust removal roo...

Embodiment 2

[0046] As an improved solution of the present invention, Embodiment 2 provides a dust removal system for an intelligent spinning workshop, such as Figure 3-6 As shown, it includes a spinning workshop 1, a dust removal room 2 and an air-conditioning room 3. The spinning workshop 1 includes a spinning equipment area and a pedestrian aisle area. The pedestrian aisle area is evenly distributed with ground dust outlets 101. Below the ground dust outlet It is an underground dust collection pipeline 102, and the top of the workshop is equipped with a top dust outlet 104, and the spinning equipment is provided with an equipment dust outlet 103; The fan is connected to blow air into the spinning workshop 1; the underground dust collection pipe 102, the equipment dust discharge port 103 and the top dust discharge port 104 are connected with the first dust discharge pipe 4, the second dust discharge pipe 5 and the third dust discharge pipe respectively. Pipeline 6 links to each other; D...

Embodiment 3

[0052] As a further preferred solution, embodiment 3 provides an intelligent spinning workshop dust removal system, the composition of the spinning workshop 1 and dust removal room 2 of the dust removal system is the same as that of embodiment 2, the difference is that the air conditioning equipment is a spray axial flow In order to cooperate with the operation of the spraying axial flow fan, the air-conditioning room is also equipped with a pool and a water pump. The spraying axial flow fan purifies the air by spraying, and then passes it into the spinning workshop 1 for recycling.

[0053] The beneficial effects of Embodiment 3 are: the spraying axial flow fan has a spraying function, which can adjust the humidity in the workshop; it can also wet the fibers or dust, thereby accelerating its fall. The recycled air after purification can maintain the temperature and humidity in the spinning workshop to a certain extent, reduce energy consumption, and thus save production costs....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com