Integrated control system and integrated control method for mining dry dust remover

A technology of integrated control system and dry dust collector, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of manual operation, time-consuming and labor-intensive, and no specific instructions, and avoid cumbersome operation, improve dust removal rate and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

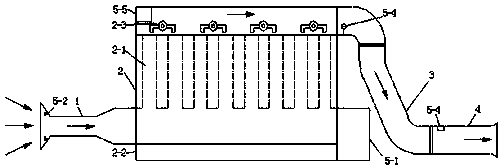

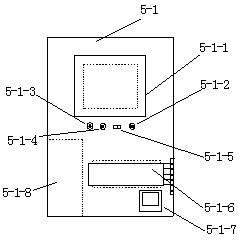

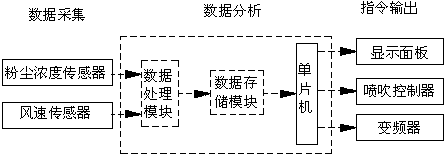

[0021] Embodiment 1: integrated control system of mine dry dust collector, including: air inlet device 1, dry dust removal box 2, filter cartridge 2-1, ash unloading box 2-2 pulse valve 2-3, connecting cylinder 3, Fan 4, integrated controller 5-1, wind speed sensor 5-2, wind speed sensor 5-3 and frequency converter 5-4; there is an air inlet device 1 on one side of the dry dust removal box 2, and a sequential connection on the other side There are connecting cylinder 3, blower fan 4 and integrated controller 5-1, there is a dust discharge box 2-2 at the bottom of the dry dust removal box 2, there is a filter cartridge 2-1 in the dry dust removal box 2, and there is a filter cartridge 2-1 in the dry dust removal box 2. The upper part of the filter cartridge 2-1 in the box 2 is connected with a pulse valve 2-3, and the upper end of the pulse valve 2-3 is connected with an injection controller 5-5; the dust concentration sensor 5-2 is set at the inlet of the air inlet device 1, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com