Plasma catalysis air purification device

An air purification device and plasma technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as unavoidable plasma and difficult to solve high power consumption of plasma, so as to improve air purification effect and solve The problem of high power consumption and the effect of small air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

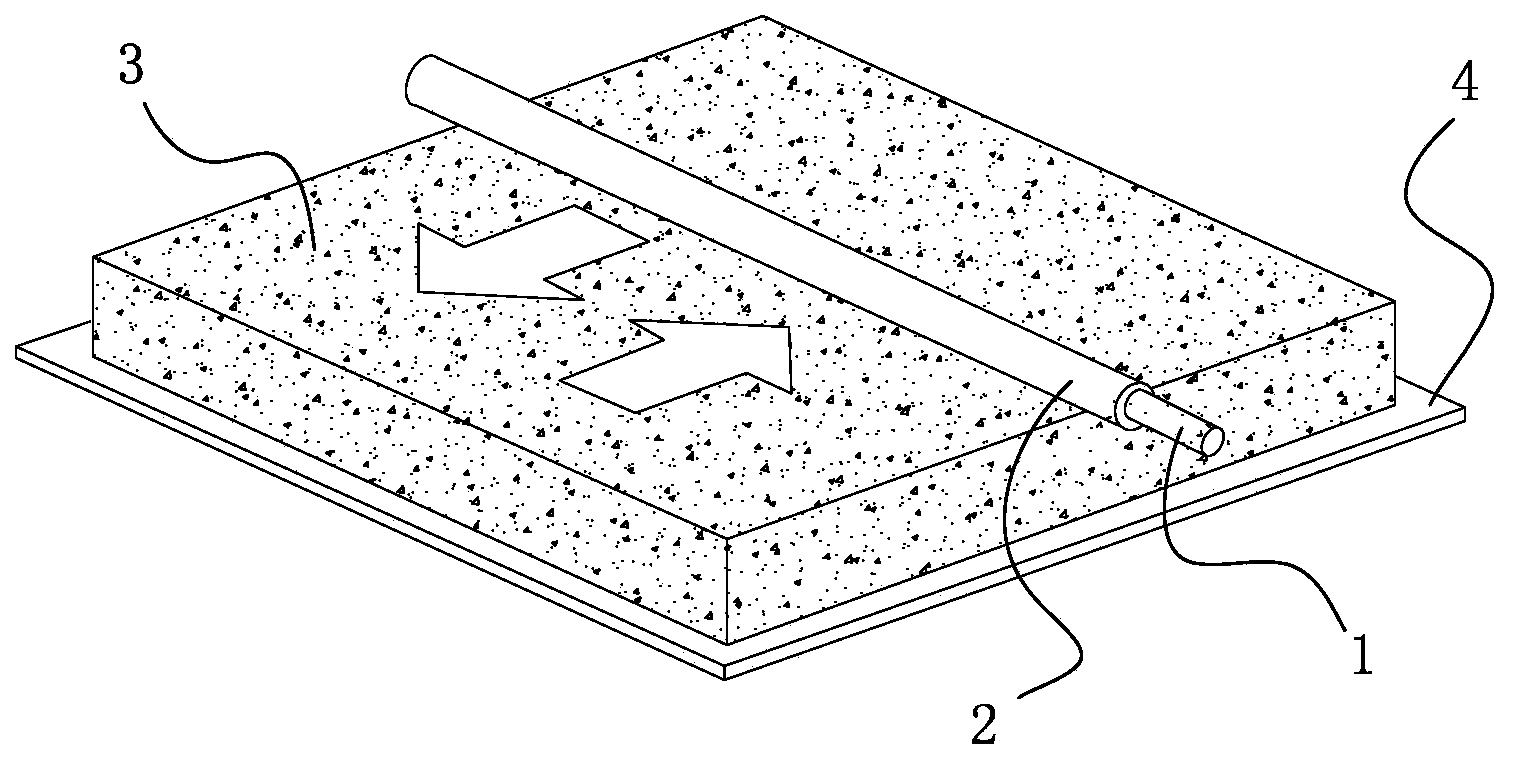

[0028] Such as figure 1 As shown, the plasma catalytic air purification device of this embodiment includes a first electrode 1 , an insulating medium 2 , a catalyst bed 3 and a second electrode 4 . Wherein, the first electrode 1 is a stainless steel rod with a diameter of 3 mm; the insulating medium 2 is a quartz tube with an inner diameter of 3 mm and a thickness of 1 mm; the catalyst bed 3 is a bed of noble metal catalyst pellets with a bed thickness of 10 mm; The second electrode 4 is an 80-mesh metal mesh.

[0029] The simulated air with a toluene concentration of 150mg / m3 is passed into the plasma catalytic purification device, and the AC high voltage of 2kHz is applied to the first electrode 1 and the second electrode 4, then the gas between the first electrode 1 and the second electrode 4 It will be broken down to form a dielectric barrier discharge plasma; the driving mechanism (such as a motor) drives the first electrode 1 to move horizontally in the direction of the...

Embodiment 2

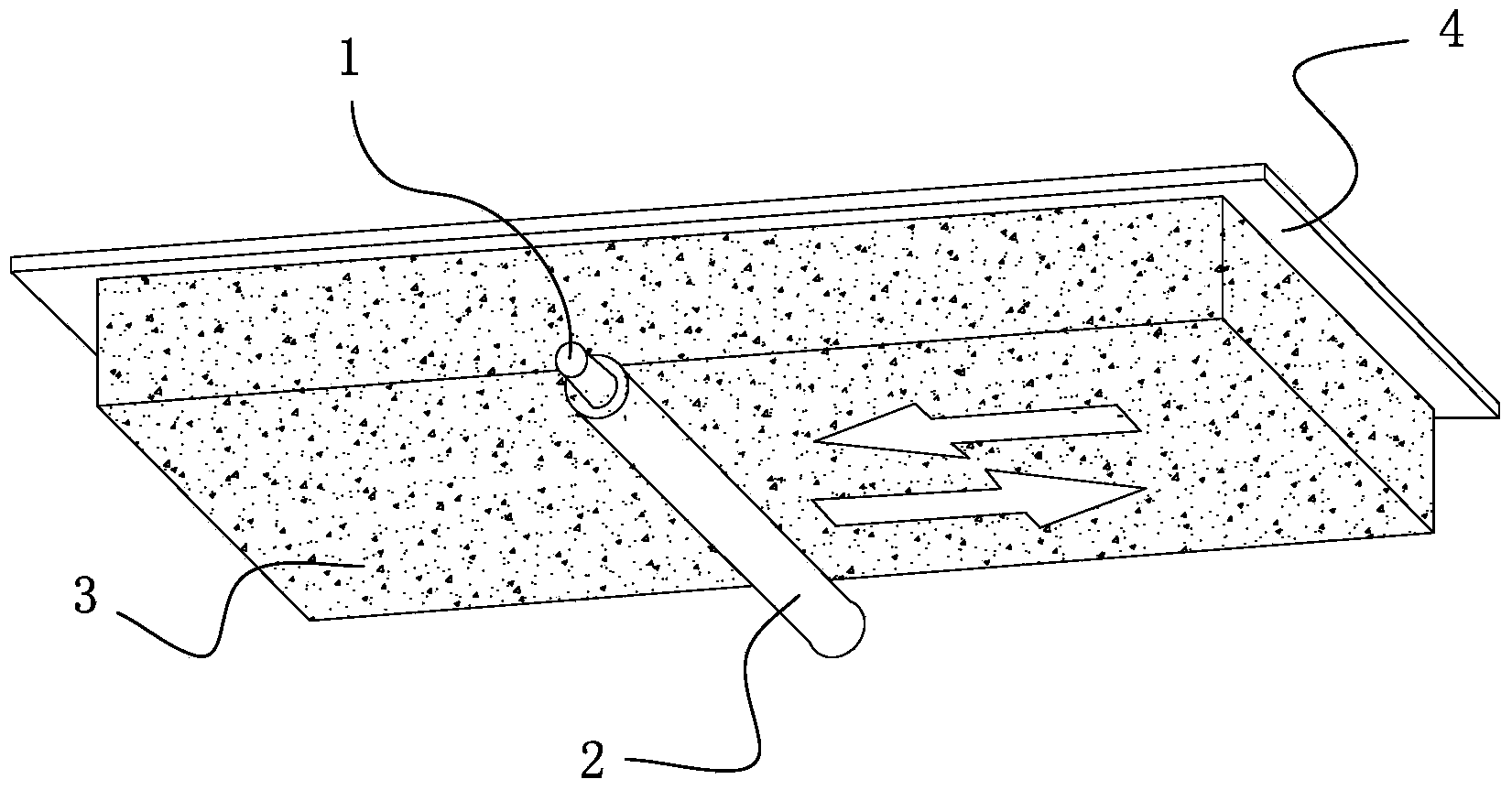

[0031] Such as figure 2 As shown, the difference from Example 1 is that the first electrode 1 in this example is placed below the catalyst bed 3 , the second electrode 4 is placed above the catalyst bed 3 , and the rest of the conditions are the same as in Example 1.

Embodiment 3

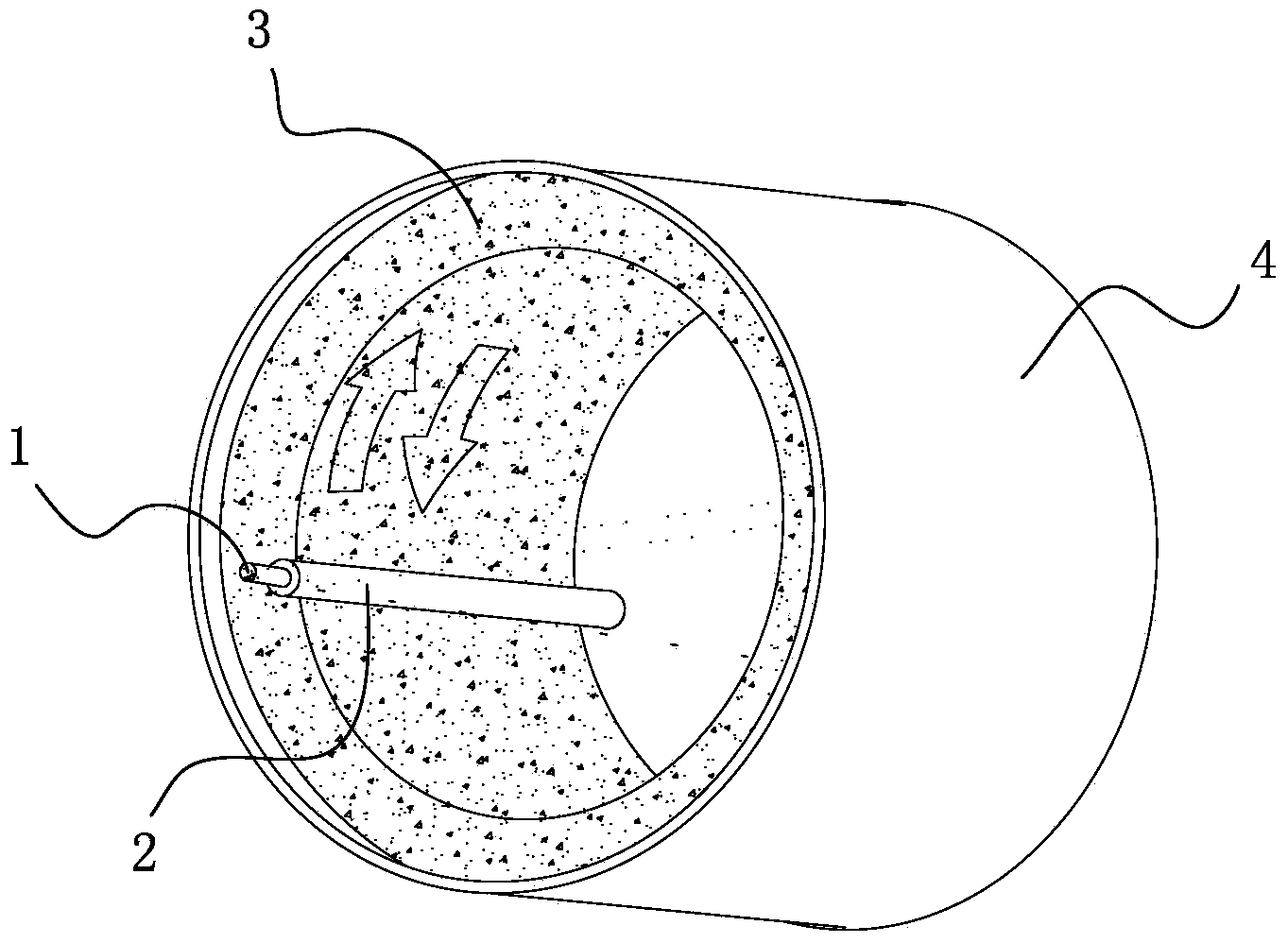

[0033] Such as image 3 As shown, the difference from Embodiment 1 is that the second electrode 4 in this embodiment is changed to a cylindrical shape, and the movement mode of the first electrode 1 is rotated around the axis at 2 r / min. The rest of the conditions are the same as in Embodiment 1. It is also possible to completely oxidize toluene to carbon dioxide and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com