Bag-type dust remover

A bag dust collector and filter bag technology, which is applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low strength and lengthening, and achieve reliable operation, large processing air volume, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

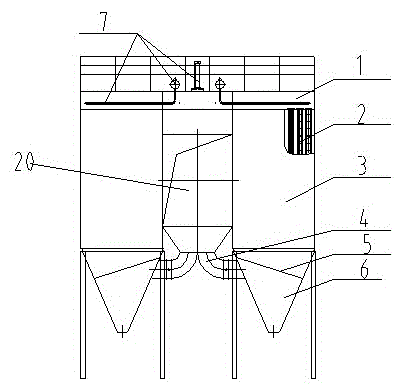

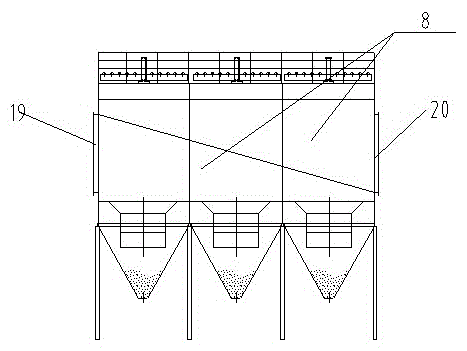

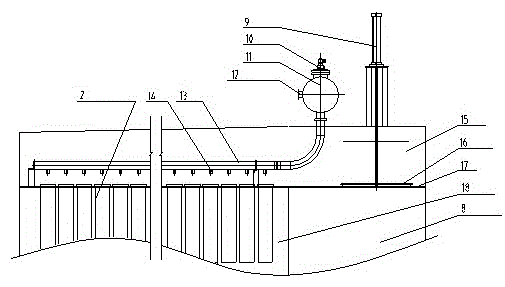

[0012] A bag filter, which consists of an upper box 1, a filter bag cage assembly 2, a middle box 3, an ash hopper air inlet system 4, an air distribution system 5, an ash hopper 6, a pulse injection system 7, and a flue gas inlet and outlet air Channel 8, cylinder 9, pulse valve 10, air distribution bag 11, compressed air inlet 12, blowing pipe 13, nozzle 14, clean air chamber 15, off-line valve plate 16, flower plate 17, filter bag chamber 18, air inlet 19 , 20 composition of gas outlet. Its working principle is: the dust-laden gas enters the filter chamber of each unit evenly from the airflow uniform distribution device at the inlet. The air flow passes through the proper flow diversion and natural flow distribution of the flow resistance plus flow diversion air distribution device, and enters the bag chamber evenly from the side and the bottom in all directions, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com