Civil engineering structure and evaporative cooling combined closed evaporative cooling cold water system

A technology for evaporative cooling and cold water systems, which is applied in air conditioning systems, heating methods, household heating, etc., can solve problems such as increasing fan production investment, increasing fan pressure, and uneven secondary air volume, so as to improve condensation efficiency, The effect of reducing wind pressure and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

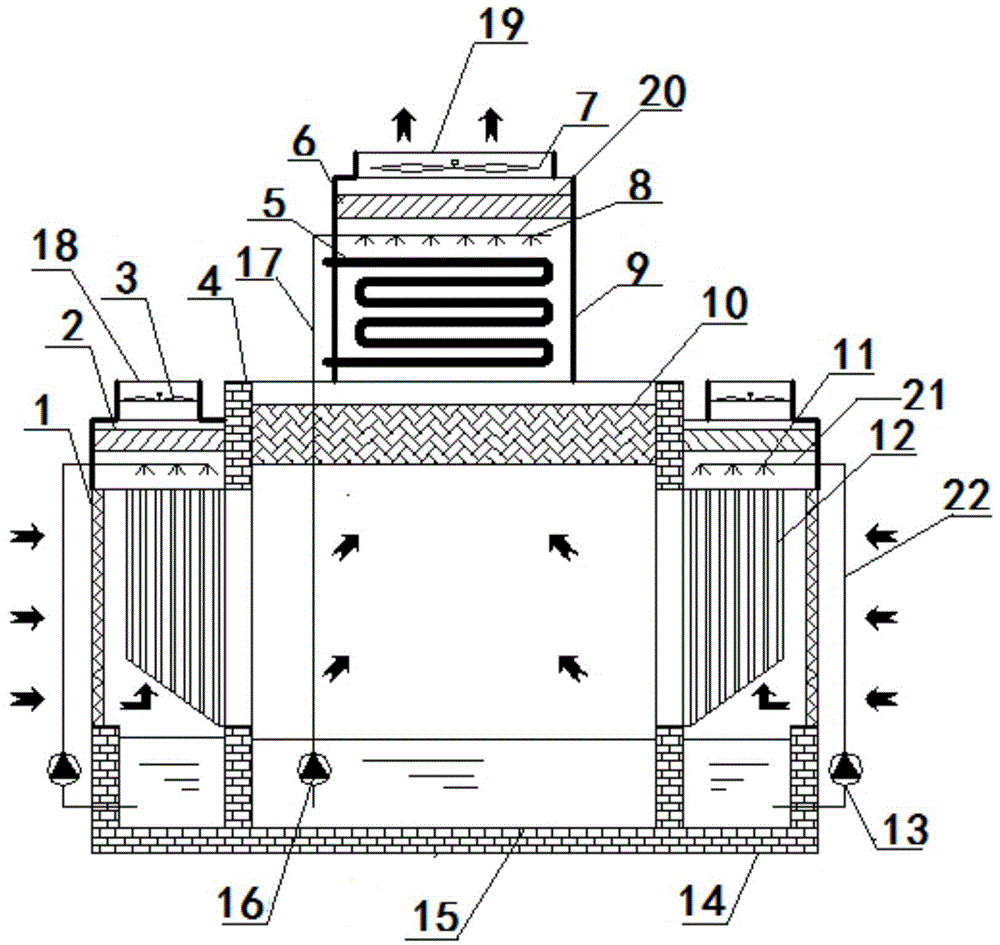

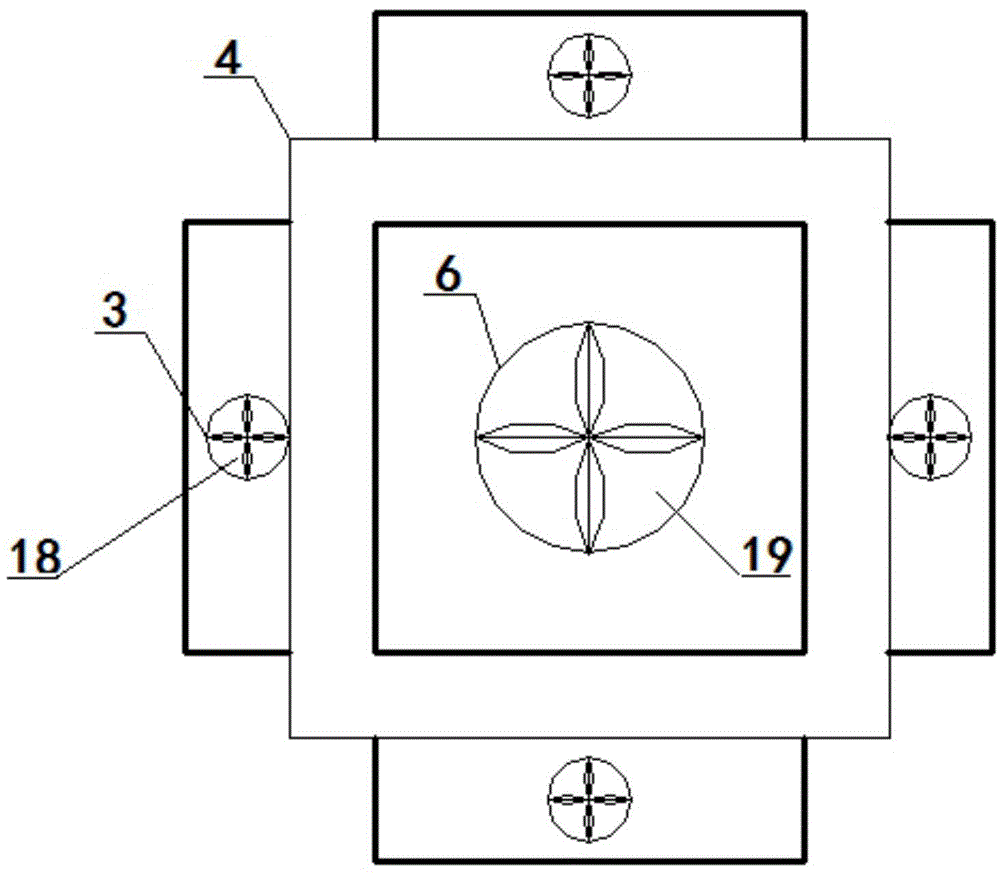

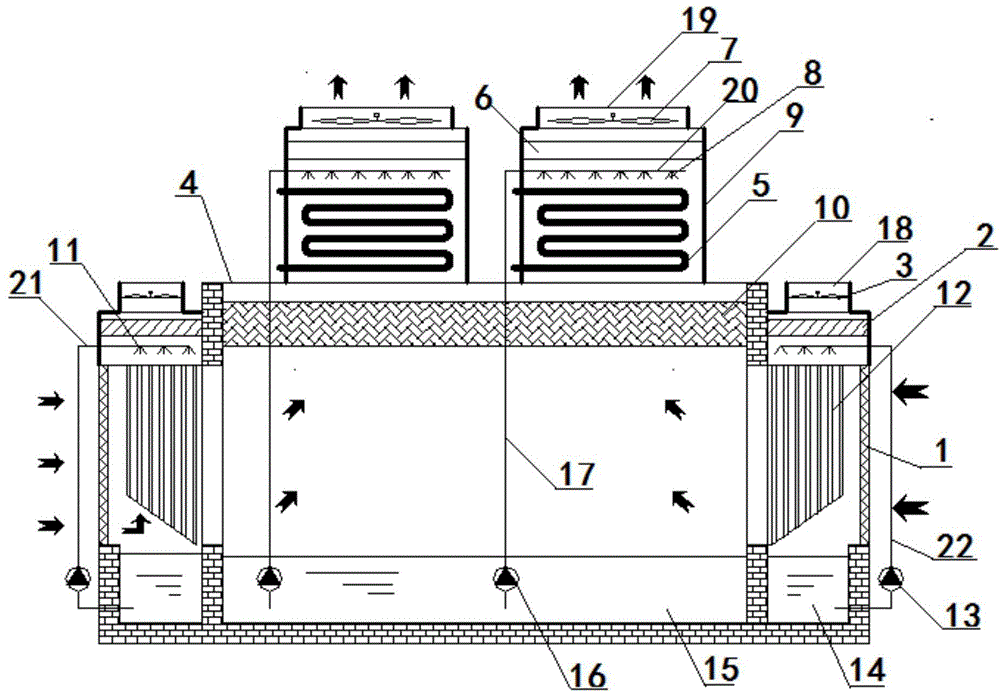

[0028] The closed evaporative cooling cold water system combining the civil structure and evaporative cooling of the present invention has a structure such as figure 1 and figure 2 As shown, it includes a civil shell 4 surrounded by civil structures, a closed heat exchange module 9 is arranged on the upper part of the civil shell 4, a packing cooling unit is arranged inside the civil shell 4, and the packing cooling unit and the closed The heat exchange modules 9 are connected, and vertical tube indirect evaporative coolers are arranged around the packing cooling unit 4 .

[0029] Closed heat exchange module 9 is provided with one or more; figure 1 and figure 2 As shown, if only one closed heat exchange module 9 is provided, the closed heat exchange module 9 is located in the center of the upper part of the civil shell 4; as image 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com