Dish type gas decontamination device

A disc type, gas technology, applied in the use of liquid separation agents, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of dust accumulation and scaling, small processing air volume, poor stability, etc., to achieve large processing air volume and stability. Strong and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

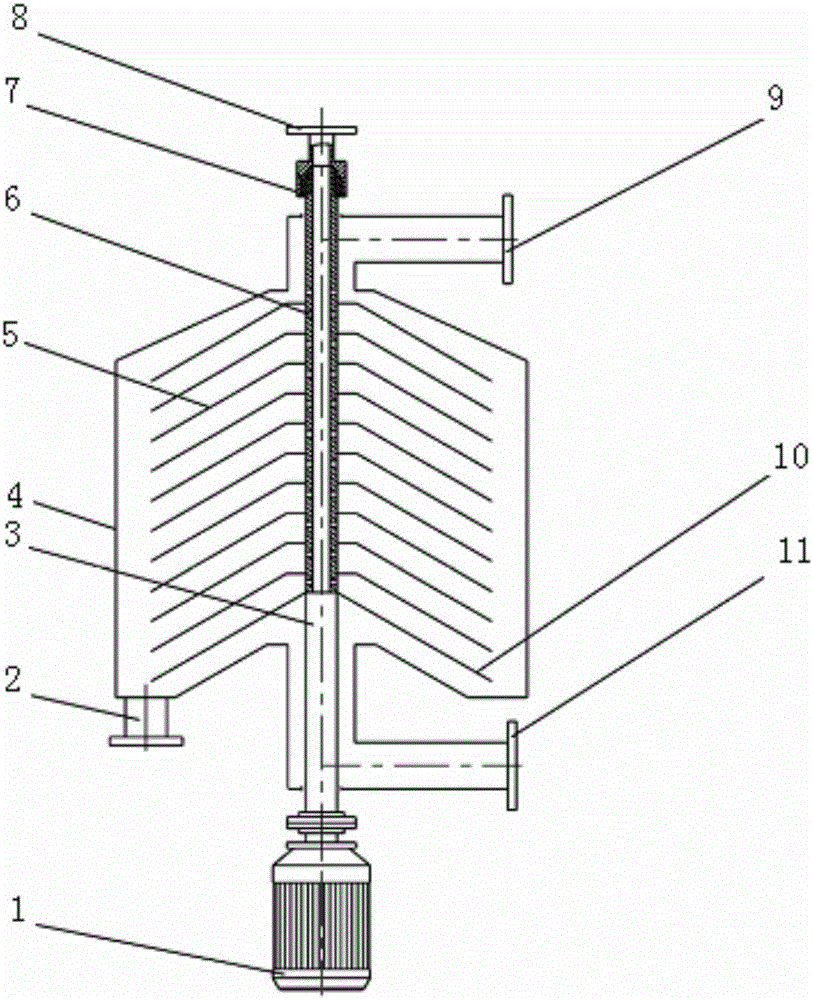

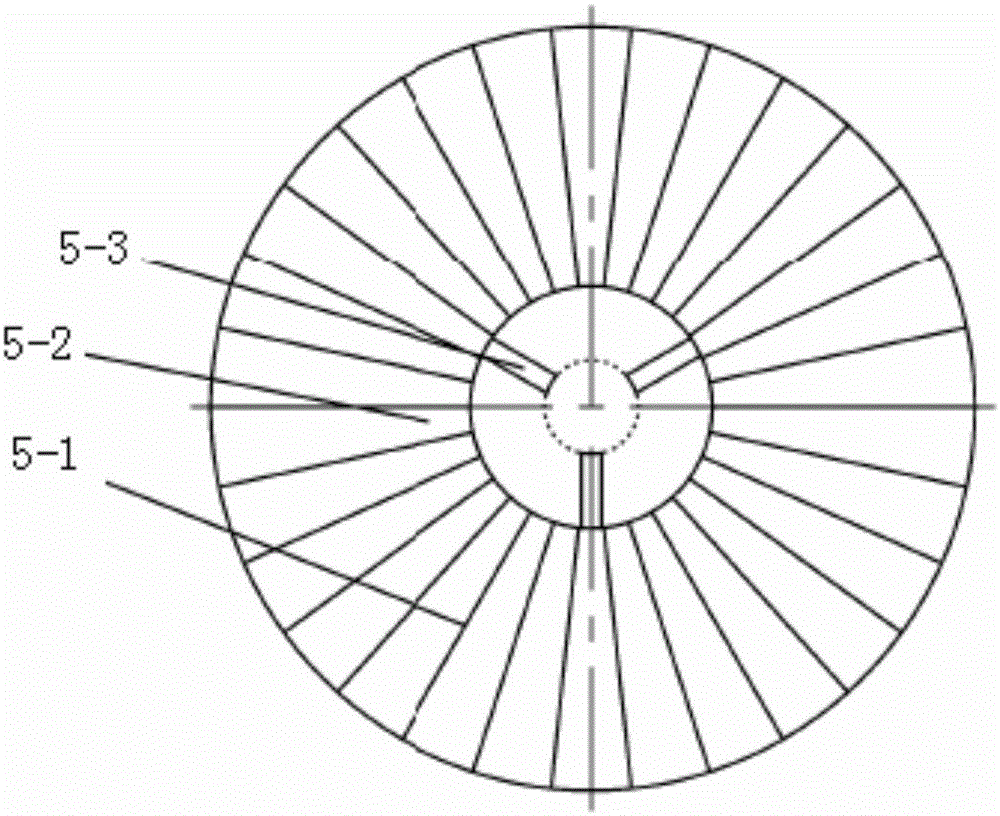

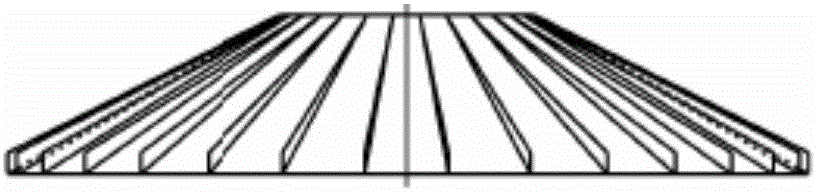

[0023] A disc-type gas decontamination device, which is used for the disposal of toxic and harmful gases containing dust, such as Figure 1 to Figure 5 As shown, it includes a rotating motor 1, a rotating shaft 3, a disc housing 4, a rotating blade 5, a liquid distributor 6, a rotating joint 7, a splitter blade 10, a liquid inlet 8, a liquid outlet 2, a gas inlet 11 and a gas outlet 9. The rotary joint 7 can be set as a single channel rotary joint. The two ends of the disc housing 4 are provided with a gas phase inlet 11 and a gas outlet 9; the rotating motor 1 drives the rotor to rotate through the rotating shaft 3, and the two ends of the rotating shaft 3 are respectively connected and sealed with the shell 4 by bearings, and the upper end of the rotating shaft 3 ( The connection part with the rotating blade 5) is a hollow structure, and a round hole is opened on the shaft wall of the rotating shaft 3 to form a liquid distributor 6. The terminal of the rotating shaft 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com