A vacuum cleaner and a control method thereof

A control method and technology for vacuum cleaners, applied in the installation of vacuum cleaners, suction filters, electrical equipment, etc., can solve the problems of insufficient dust removal effect, troublesome cleaning of dust collectors, poor liquid separation effect, etc., to improve user experience and compact structure. , Improve the effect of vacuuming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

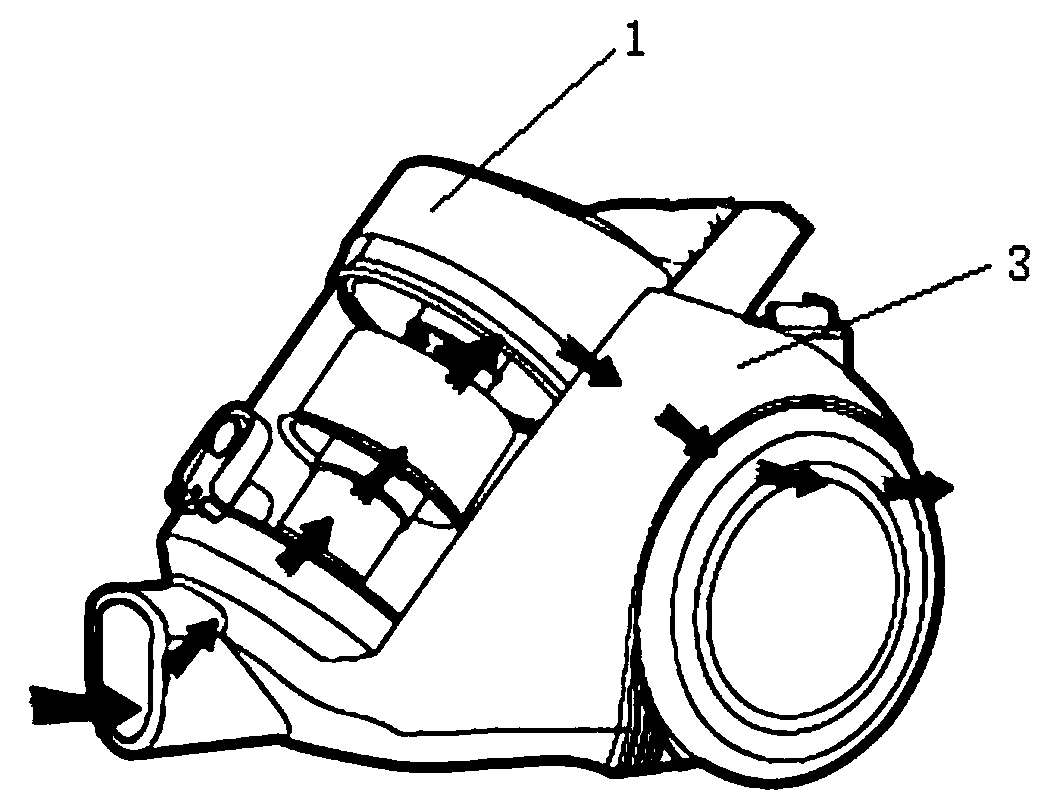

[0041] In order to solve the problems existing in the prior art, this embodiment provides a structure of the vacuum cleaner, specifically, refer to Figure 1 to Figure 4, the vacuum cleaner includes a dust collection device 1 and a main body 3, the dust collection device 1 is detachably installed on the main body 3, the dust collection device 1 is used to separate and collect garbage; the main body 3 is provided with Suction motor and fan, the suction motor starts behind the drive motor 15 and stops earlier than the drive motor 15, the suction motor drives the fan to rotate to generate suction, and the dusty air is sucked to the In the main body 3 of the vacuum cleaner.

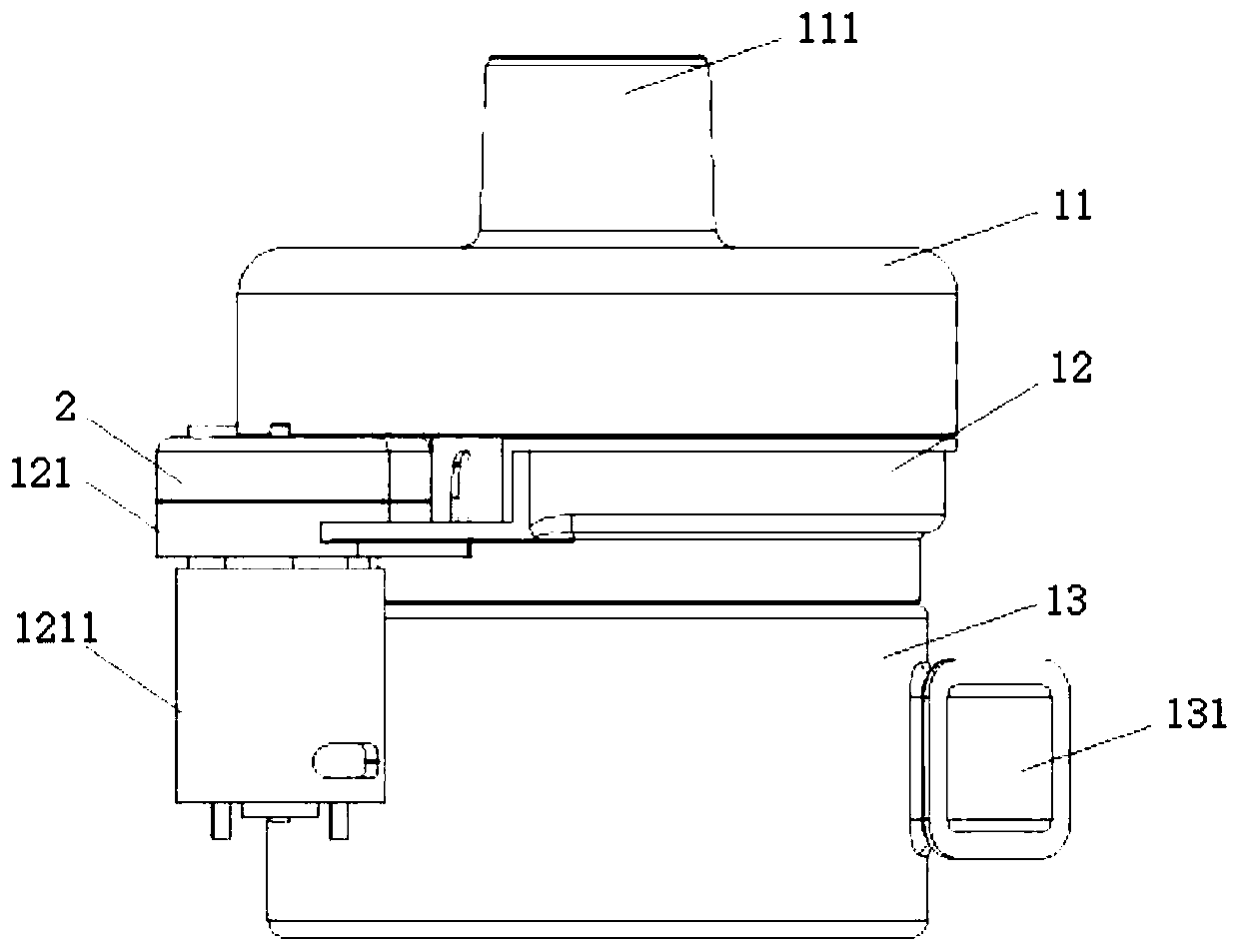

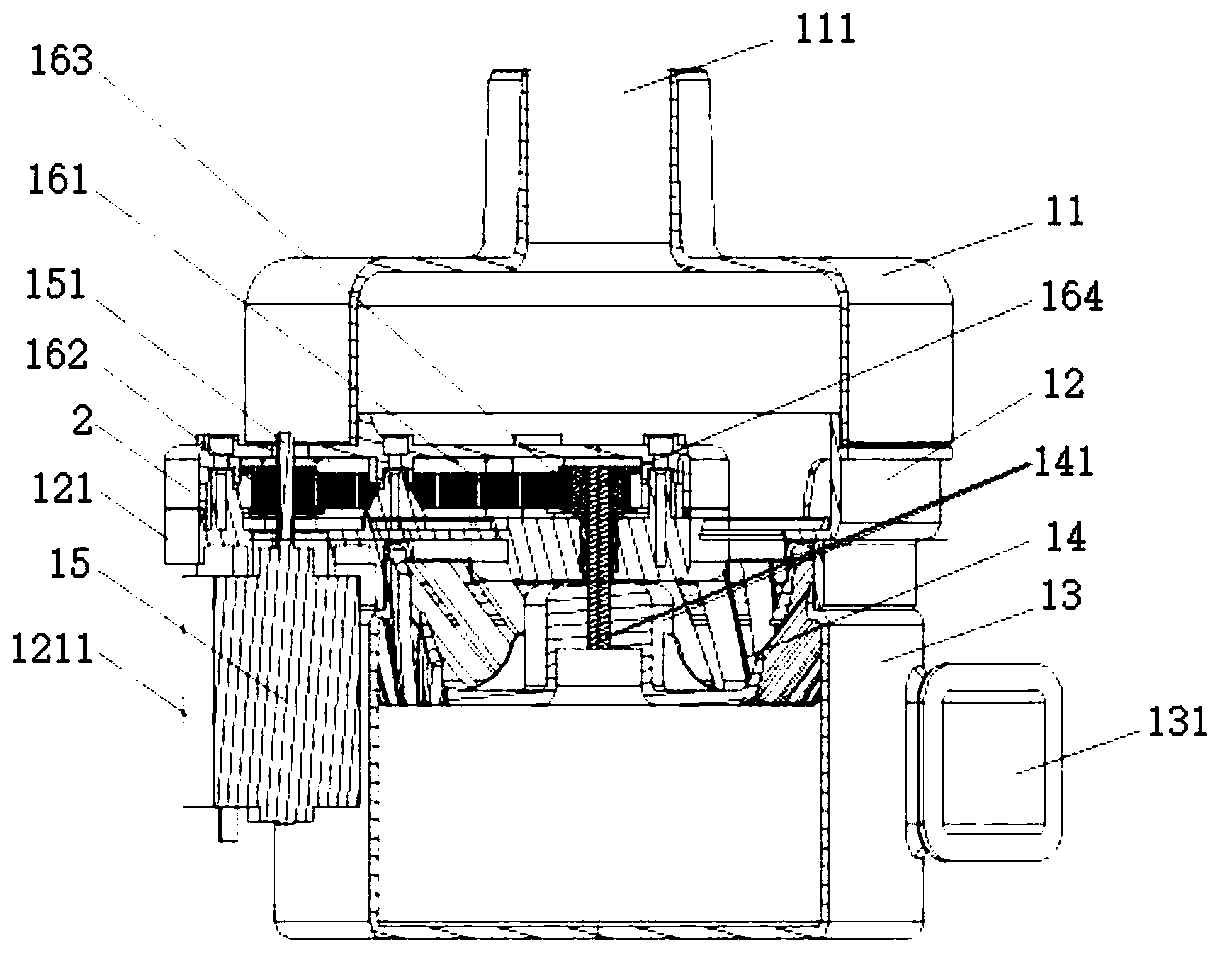

[0042] In an implementable solution, the dust collecting device 1 includes a driving motor 15, a separator 14, a separator driving device 16, a housing 11, a partition support 12 and a dust cup 13, and the driving motor 15 passes through the The separator driving device 16 drives the separator 14 to rotate, ...

Embodiment approach

[0053] As an embodiment, the dust collecting device 1 further includes a sealing cover 2, and the sealing cover 2 is closed and connected with the partition bracket 12 to form a cavity.

[0054] The support part 121 has a first through hole, the output shaft 151 of the driving device 15 enters the cavity through the first through hole, and is connected with the first transmission wheel 162; 12 has a second through hole, the rotating shaft 164 enters the cavity through the second through hole, and is connected with the second transmission wheel 163 . The supporting part 121 further includes a box body 1211 for accommodating the driving motor 15 .

[0055] As an embodiment, a plurality of positioning parts are arranged in the cavity, which are used to limit the movement track of the transmission belt, fix the position of the transmission belt, and prevent the transmission belt from coming out. In a possible implementation manner, the positioning member is a positioning column, ...

Embodiment 2

[0072] In order to solve the problems existing in the prior art, this embodiment provides another structure of the vacuum cleaner. Specifically, in this embodiment, please refer to the detailed description of Embodiment 1 for details not involved in this embodiment.

[0073] Specifically, in this embodiment, participating Figure 5 to Figure 7 , the housing 11 is connected to the dust cup 13, the partition bracket 12 is arranged in the accommodating cavity formed by the housing 11 and the dust cup 13, and the partition bracket 12 includes a partition and a connecting cylinder, the partition is provided with a first hollow structure for the passage of fluid, one side of the partition is connected to the housing, and the other side of the partition is connected to the connecting cylinder, the The connecting cylinder extends into the dust cup.

[0074] Further, in this embodiment, the axis of the driving motor 15 coincides with the rotation axis of the separator 14 , and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com