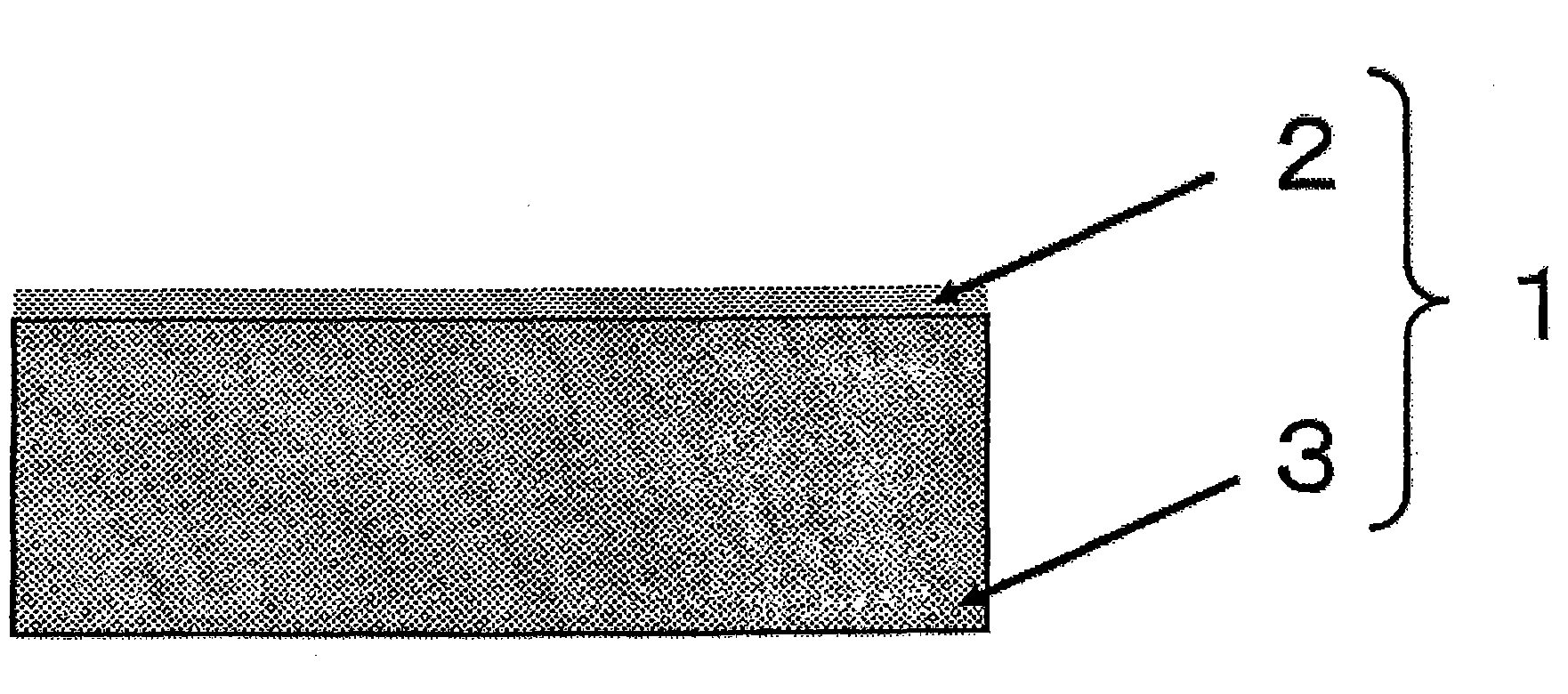

Antistatic filtering cloth in surface filtering mode for dust collector

A surface filter and dust collector technology, applied in the field of filter cloth, can solve the problems of not having high softness, high mechanical strength, dust collection performance, adverse effects of dust falling performance, and inability to maintain dust collection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

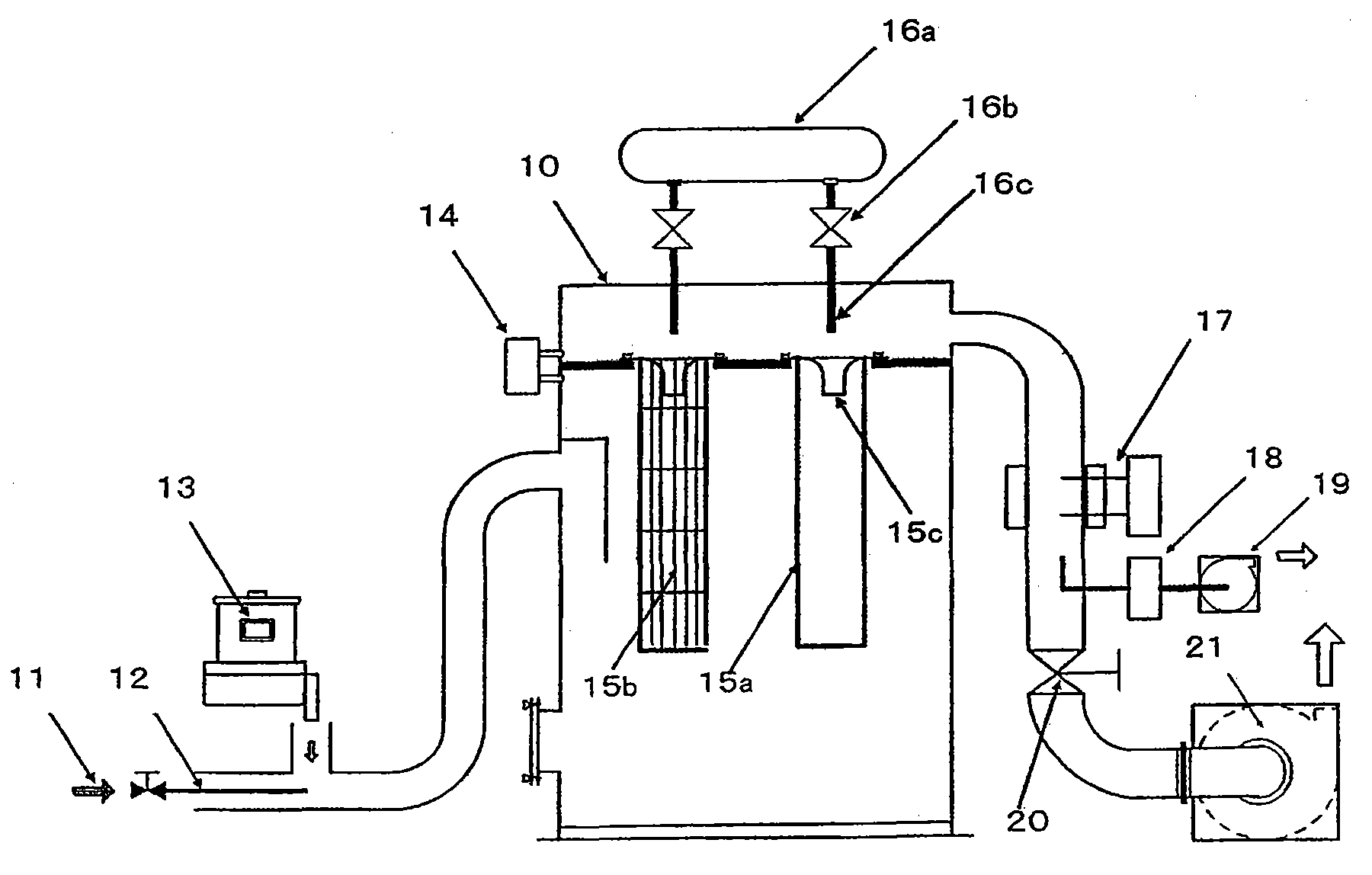

Method used

Image

Examples

Embodiment 1

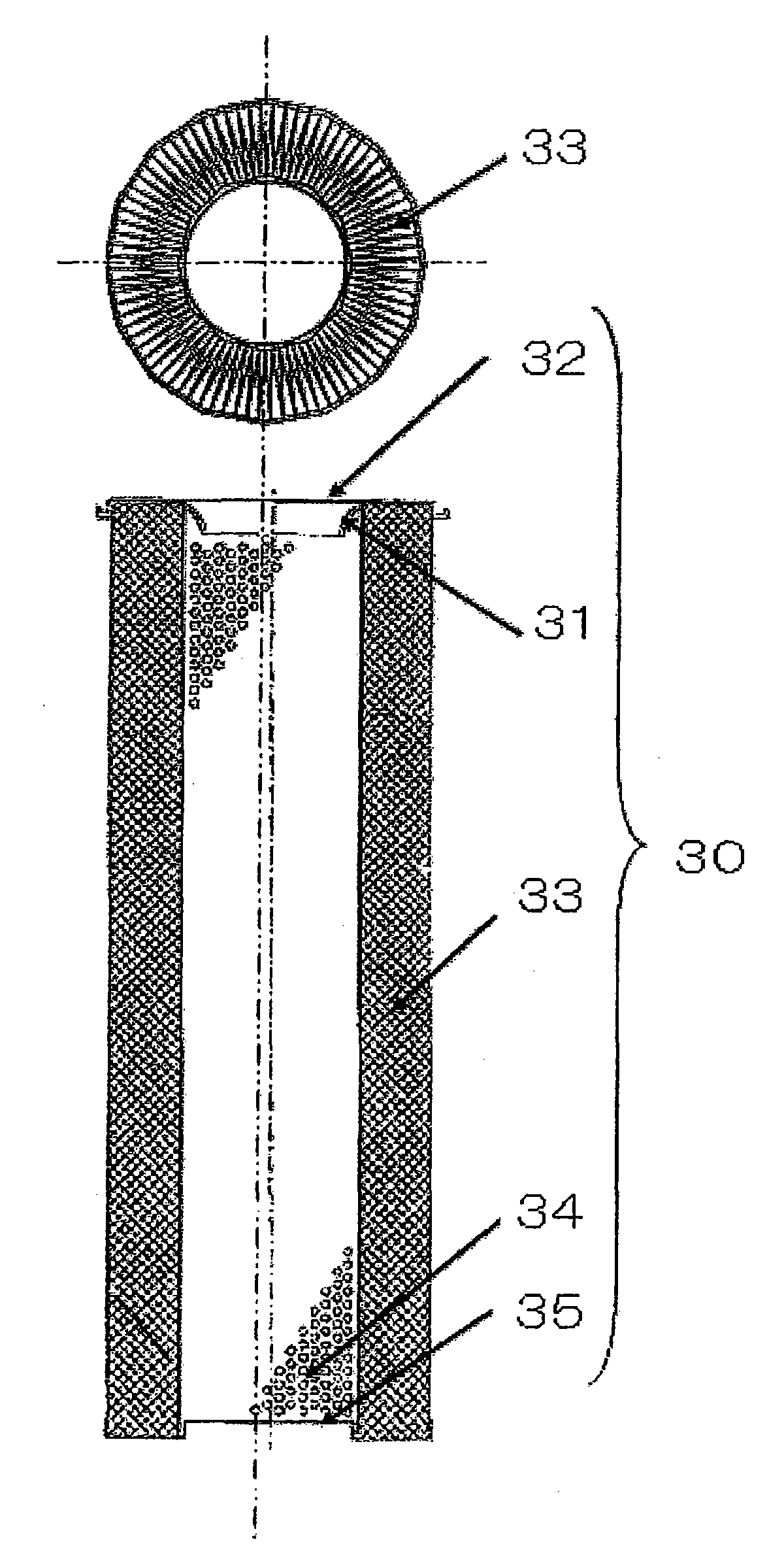

[0032](Preparation of cylindrical filter cloth based on a mixture of carbon nanofibers and organic binders)

[0033] As the carbon nanofibers, use CNT aqueous dispersion product "Mikoku Pigment Co., Ltd., product name: CNTDW-80, solvent: water, CNT concentration: 11.5% by weight, "CNT after use" (Showa Denko Co., Ltd., trade name: VGCF, Fiber diameter: 150nm, length: 10-20μm)", as an organic binder, an aqueous solution of shellac resin (manufactured by THE JAPAN SHELLAC INDUSTRIES Co., Ltd. , product name: SB-25, solvent: water, shellac resin concentration: 23.5% by weight, borax 5.5% by weight), with above-mentioned nano-carbon fiber, organic binder and ion-exchanged water, with CNT solid content: shellac resin The ratio of solid content: ion-exchanged water = 2.0:0.1:97.9 was compounded. Then, mixing was performed at 11000 rpm for 5 minutes using a homogenizer (manufactured by IKA, trade name: ULTRA-TURRAXT25) to obtain a mixed liquid (1 g of the mixed liquid contained 20 m...

Embodiment 2

[0036] (Preparation of cylindrical filter cloth based on a mixture of carbon nanofibers and inorganic binders)

[0037] With the CNT aqueous dispersion product (the same raw material as embodiment 1) as carbon nanofiber, the amorphous silica aqueous solution (manufactured by Grandex Corporation, trade name: FJ294, solvent: water, amorphous silica) as inorganic binder Concentration: 37% by weight), and ion-exchanged water were mixed at a ratio of CNT solid content:amorphous silica solid content:ion-exchanged water=2.0:0.1:97.9. Then, mixing was performed at 11,000 rpm for 5 minutes using a homogenizer to prepare a mixed liquid (20 mg of CNT is contained in 1 g of the mixed liquid). The mixed solution at 120g / m 2 The treatment capacity is sprayed on the polyester needle-punched non-woven fabric (weight per unit area 600g / m 2 ) on the filter surface side (singeing treatment surface), and then dried at 120° C. for 1 hour. The dried non-woven fabric is sewn into Cylindrical ty...

Embodiment 3

[0039] (Preparation of cylindrical filter cloth in which carbon nanofibers are immobilized by melting nonwoven fabric)

[0040] A CNT water dispersion (the same raw material as in Example 1) and ion-exchanged water as carbon nanofibers were mixed at a ratio of CNT solid content: ion-exchanged water = 2.0:98.0. Then, mixing was performed at 11000 rpm for 5 minutes using a homogenizer to obtain a dispersion (20 mg of CNTs are contained in 1 g of the dispersion). The dispersion is 120g / m 2 The treatment capacity is sprayed on the polyester needle-punched non-woven fabric (weight per unit area 600g / m 2 ) on the filter side (singeing treatment side), dry at 120°C for 1 hour. Then, the non-woven fabric is crimped with a heating roll controlled at 250°C, and after cooling, it is sewn into a Cylindrical type to obtain cylindrical filter cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com