Handheld dust collector with spiral two-level tornado dust-air separation structure

A dust-gas separation and vacuum cleaner technology, applied in the direction of vacuum cleaners, suction filters, household appliances, etc., can solve the problems of low air volume, low filtration efficiency, and limited storage space of the whole machine, so as to simplify the assembly process, improve the overall performance, improve the The effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

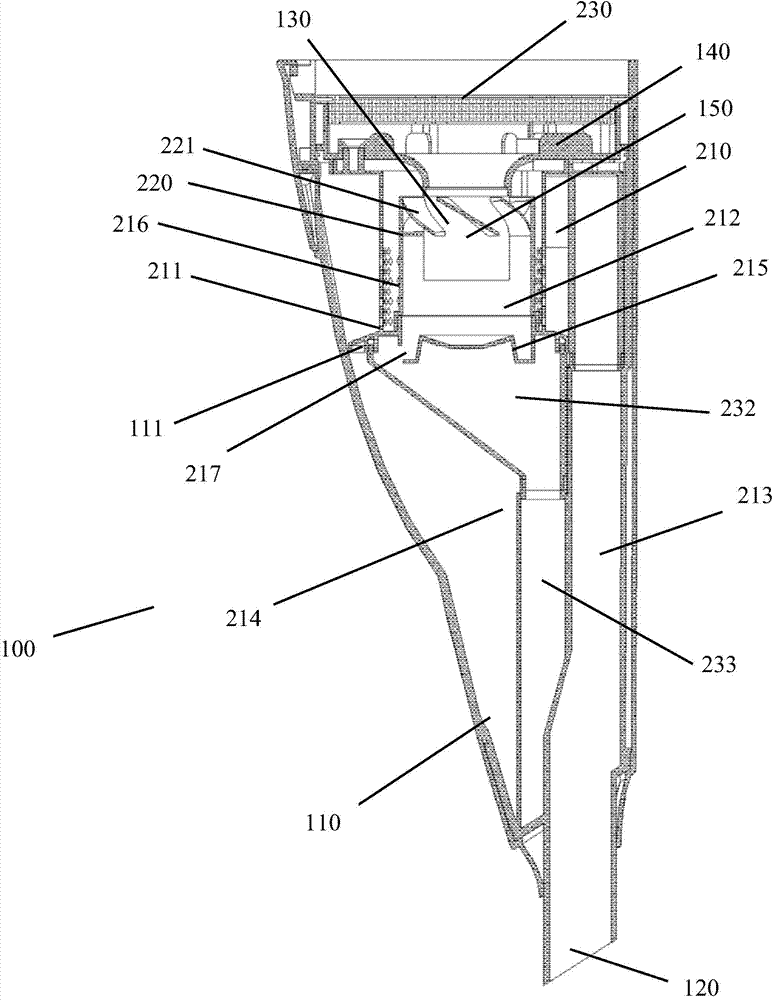

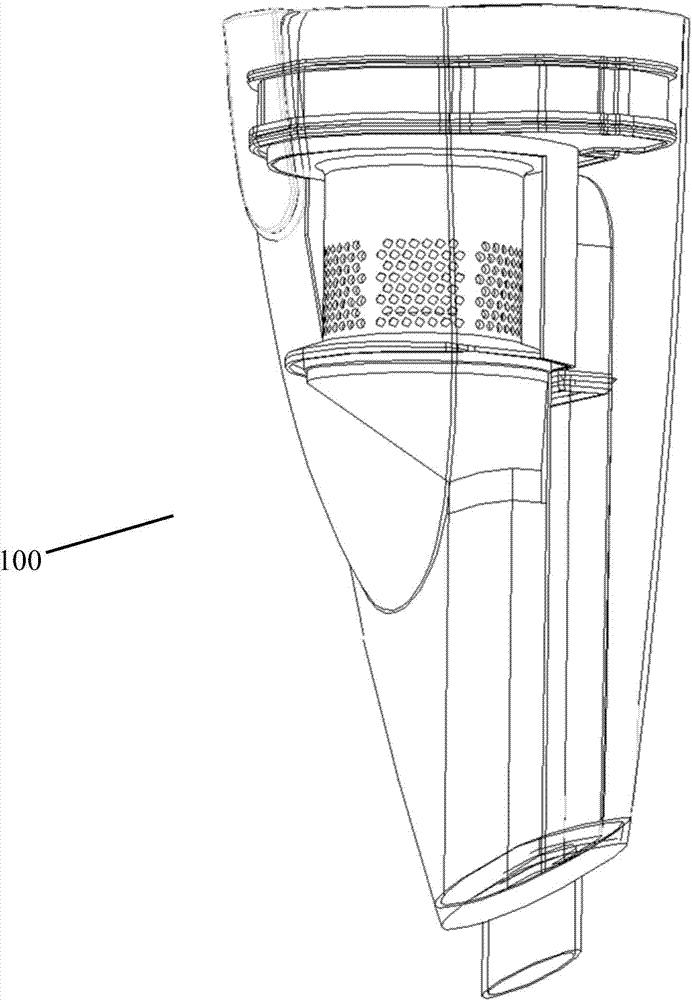

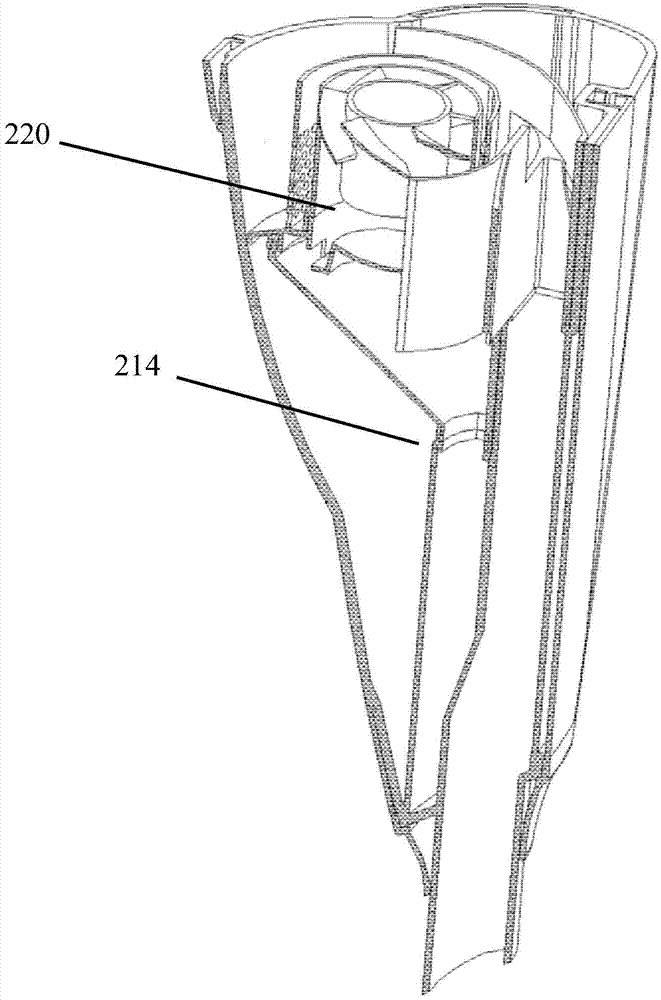

[0041] The traditional two-stage dust-gas separation structure requires many parts, and the molds and assembly processes involved are relatively many and complicated. The sealing of each link is difficult to control, and it is prone to air leakage and dust leakage, which affects the overall performance of the whole machine. performance. In addition, the previous two-stage dust-gas separation type fuselage structure is axial layout, which makes the ratio of the filter structure to the space of the fuselage larger, and takes up too much dust collection volume of the fuselage, and the ash storage space is limited. , and this type of secondary dust-gas separation body structure requires a relatively high and large body volume, and its shape is not suitable for portable hand-held vacuum cleaners, and the scope of use is limited.

[0042]Aiming at the deficiencies in the prior art, the present invention provides a hand-held vacuum cleaner with a spiral two-stage tornado dust-air sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com