Patents

Literature

40results about How to "Increase the amount of compounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

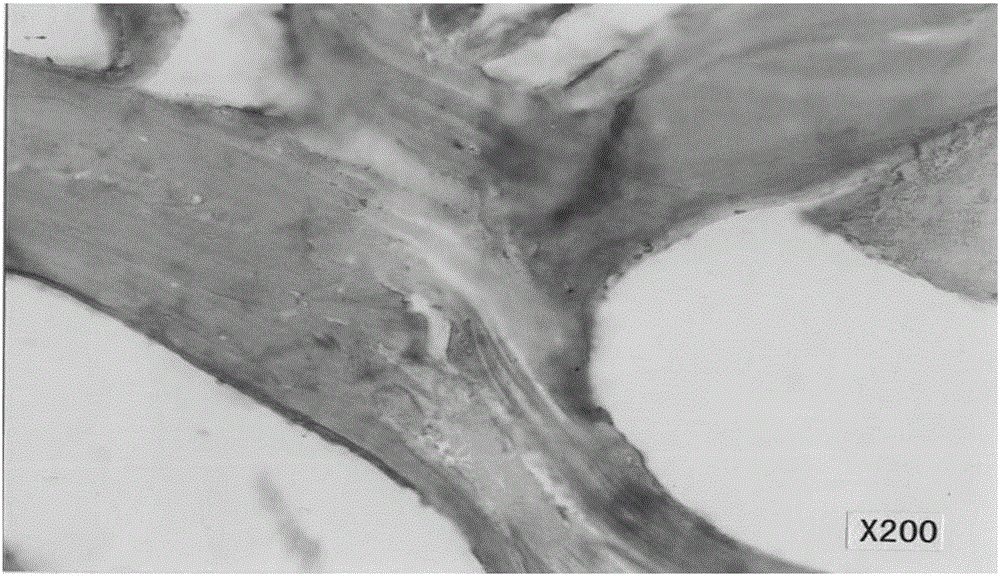

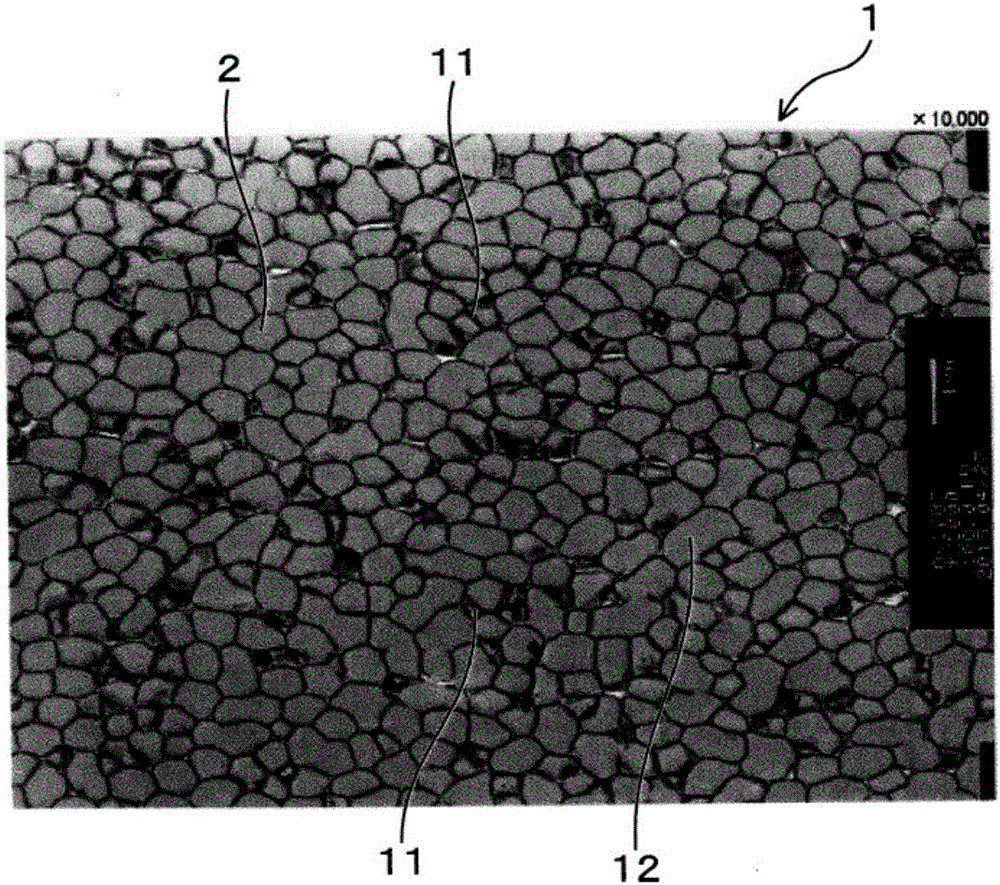

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

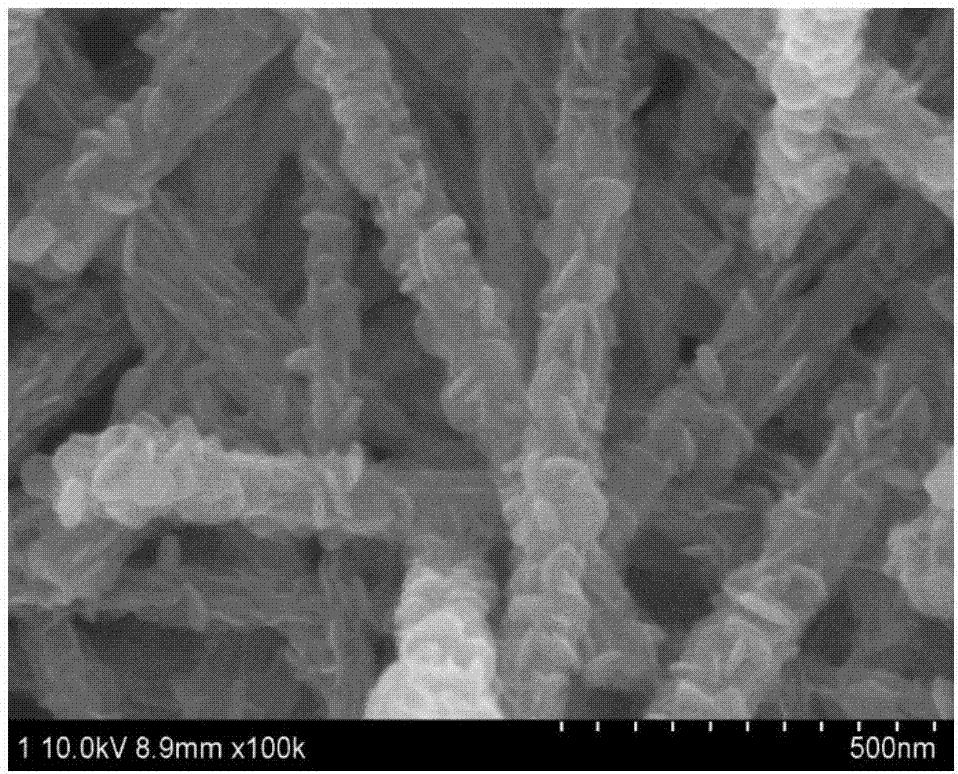

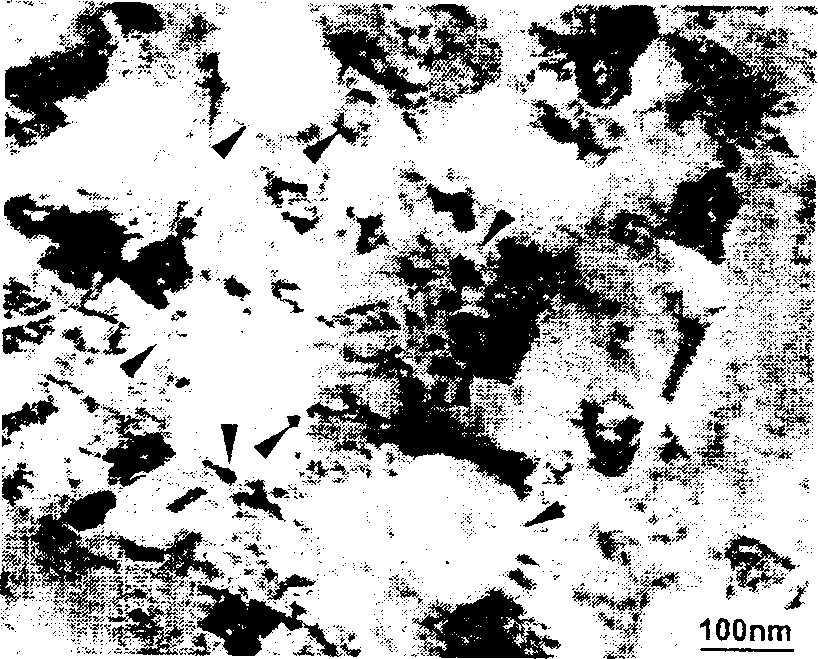

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

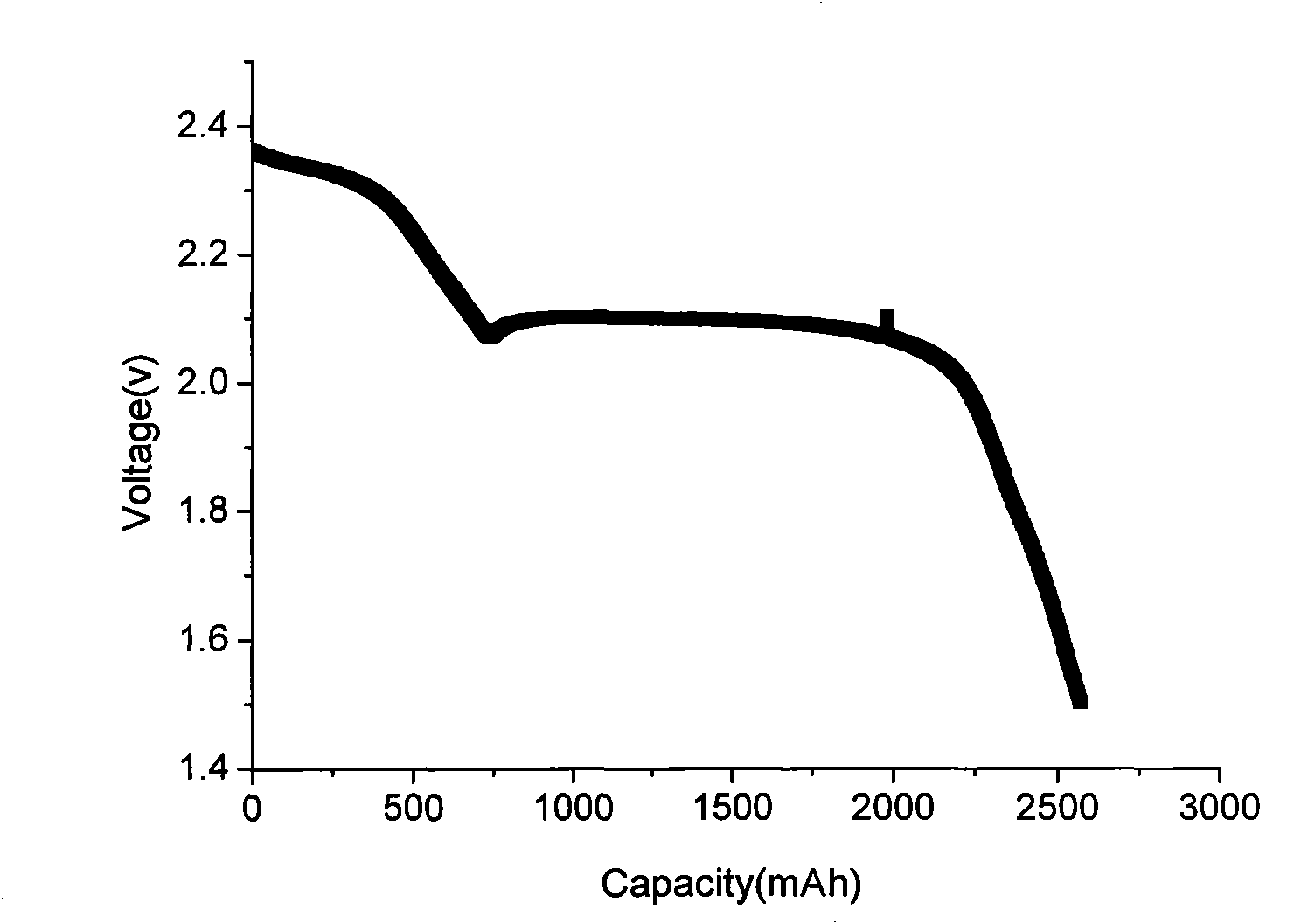

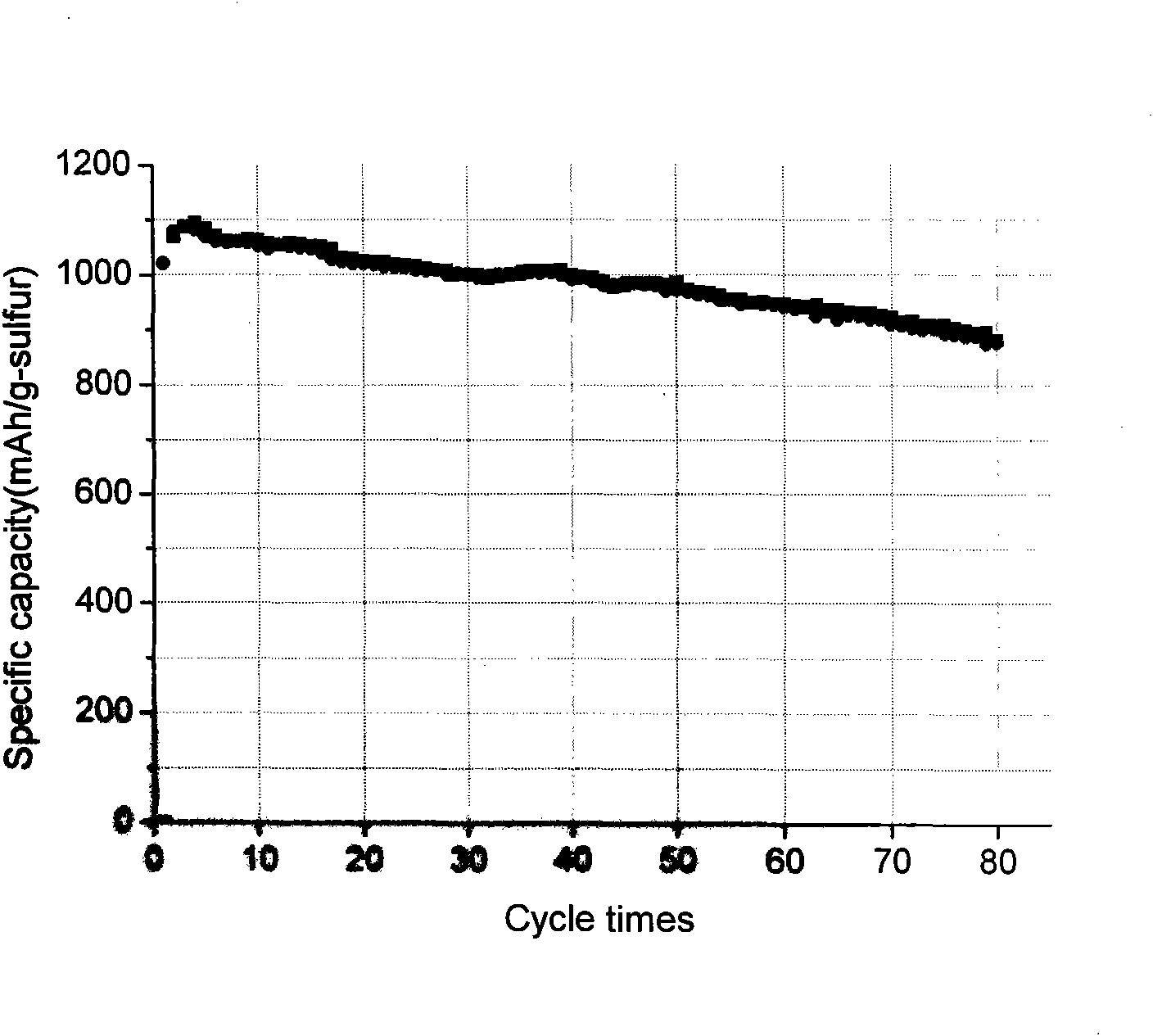

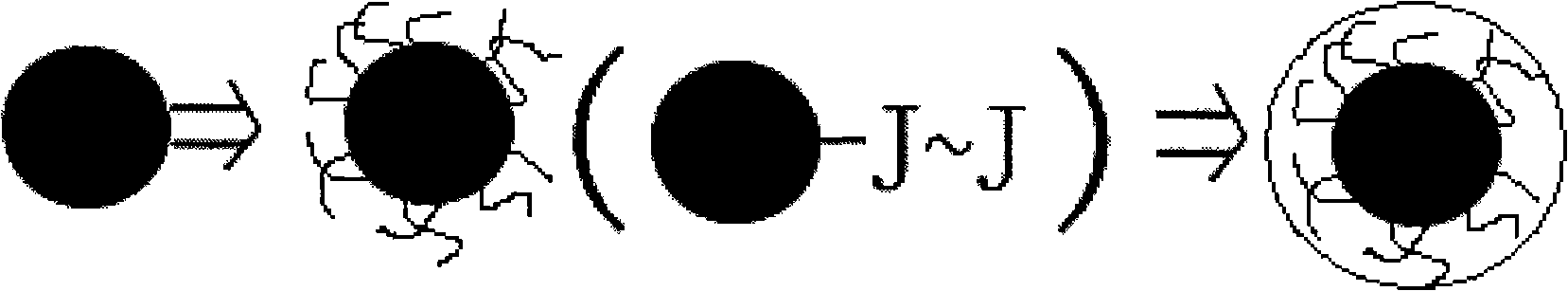

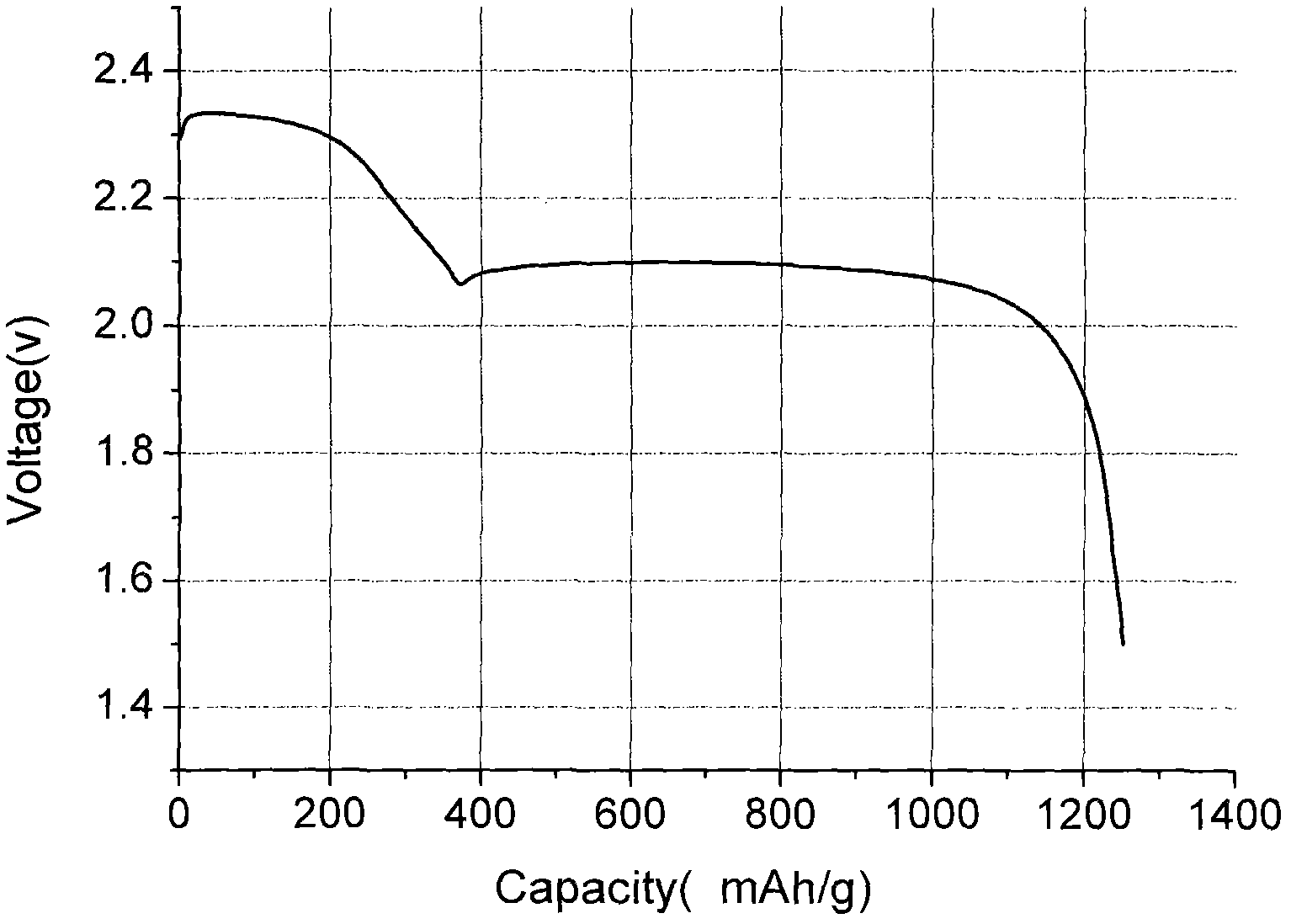

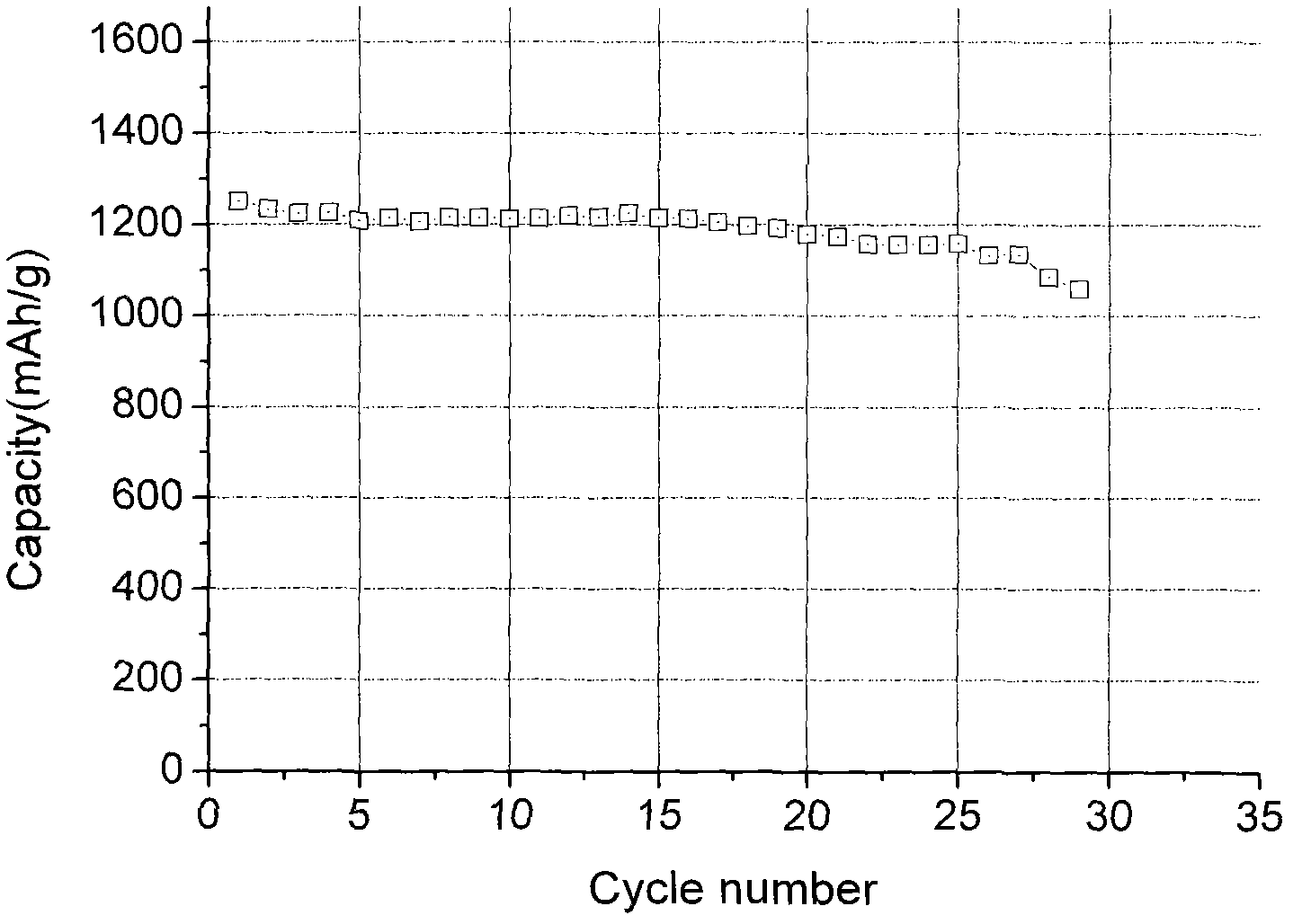

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

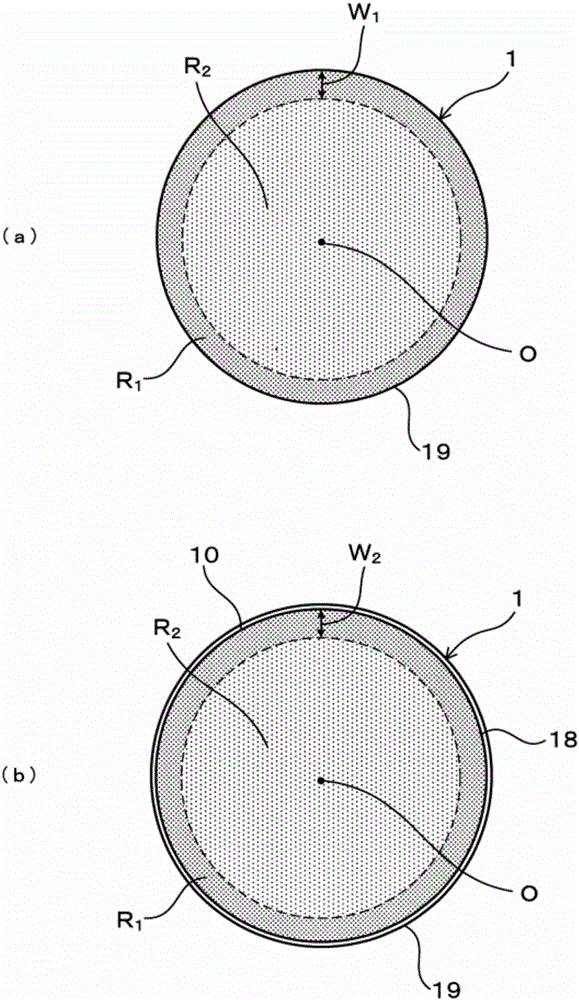

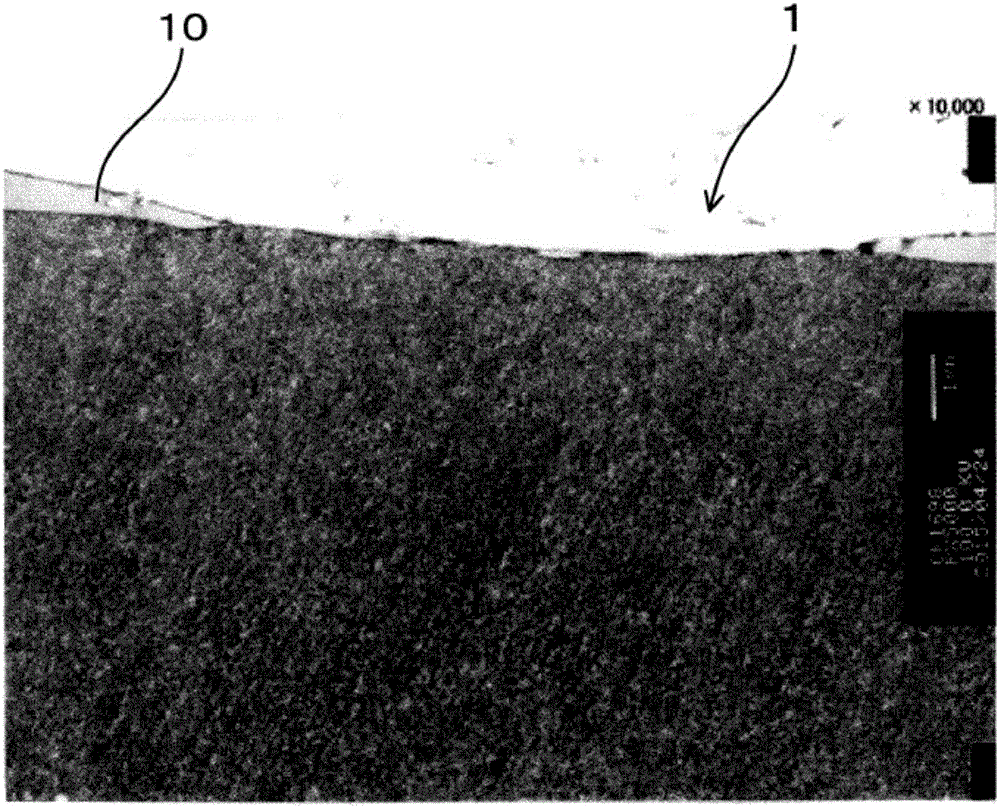

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

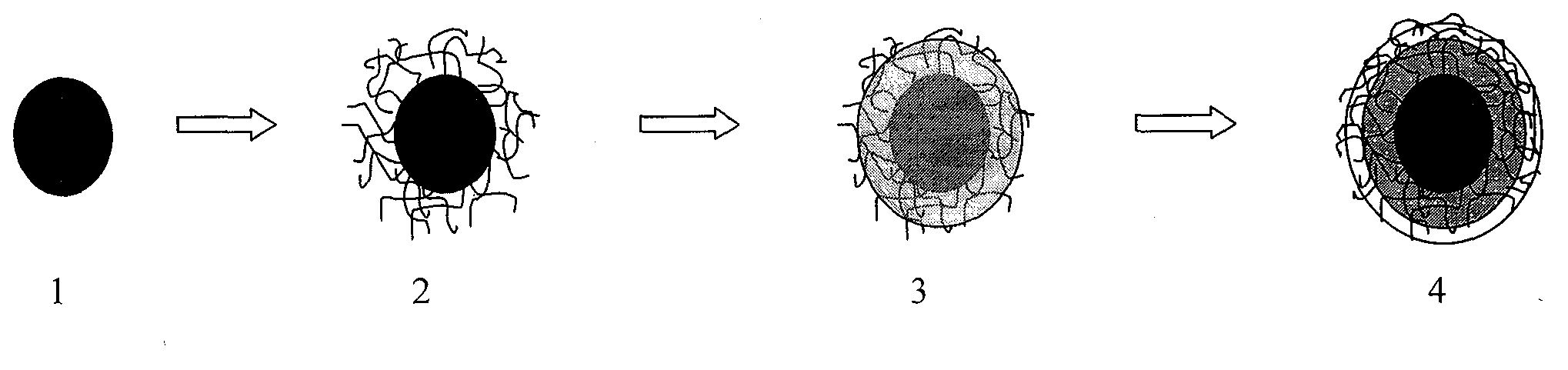

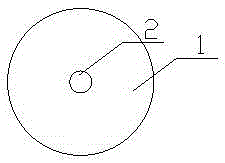

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

Filtering material of thermal stability and the purpose thereof

InactiveCN101032674AHigh mechanical strengthReduce thermal shrinkageFiltration separationFiberHeat resistance

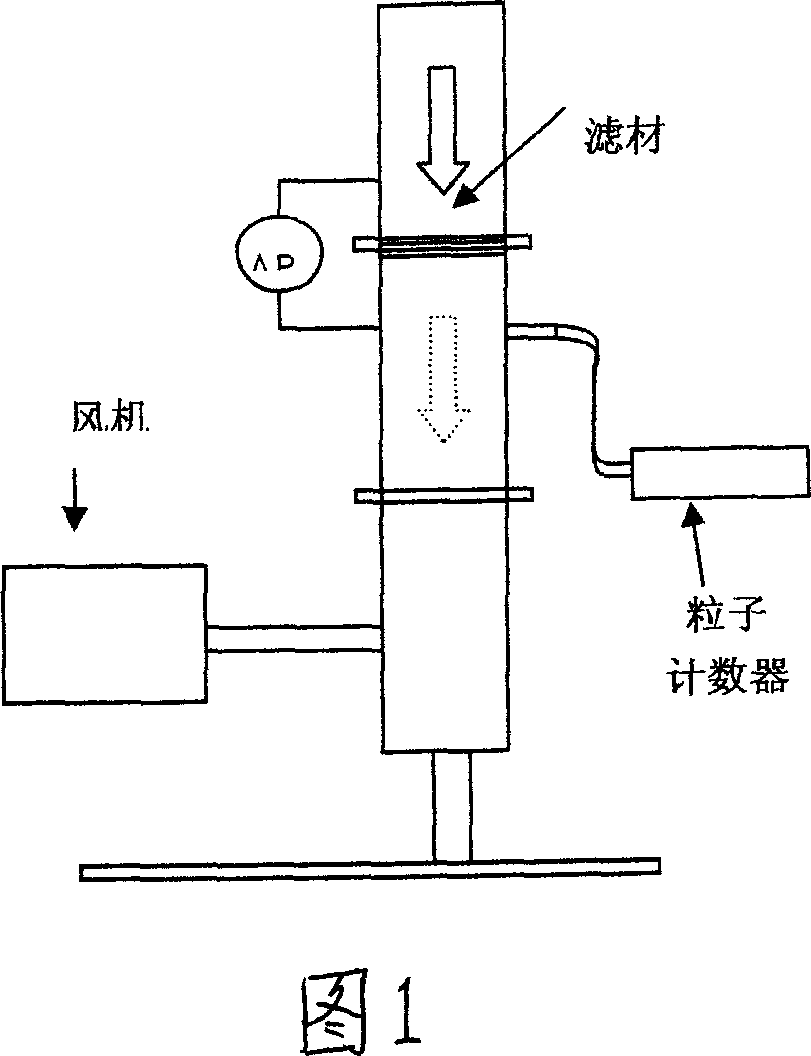

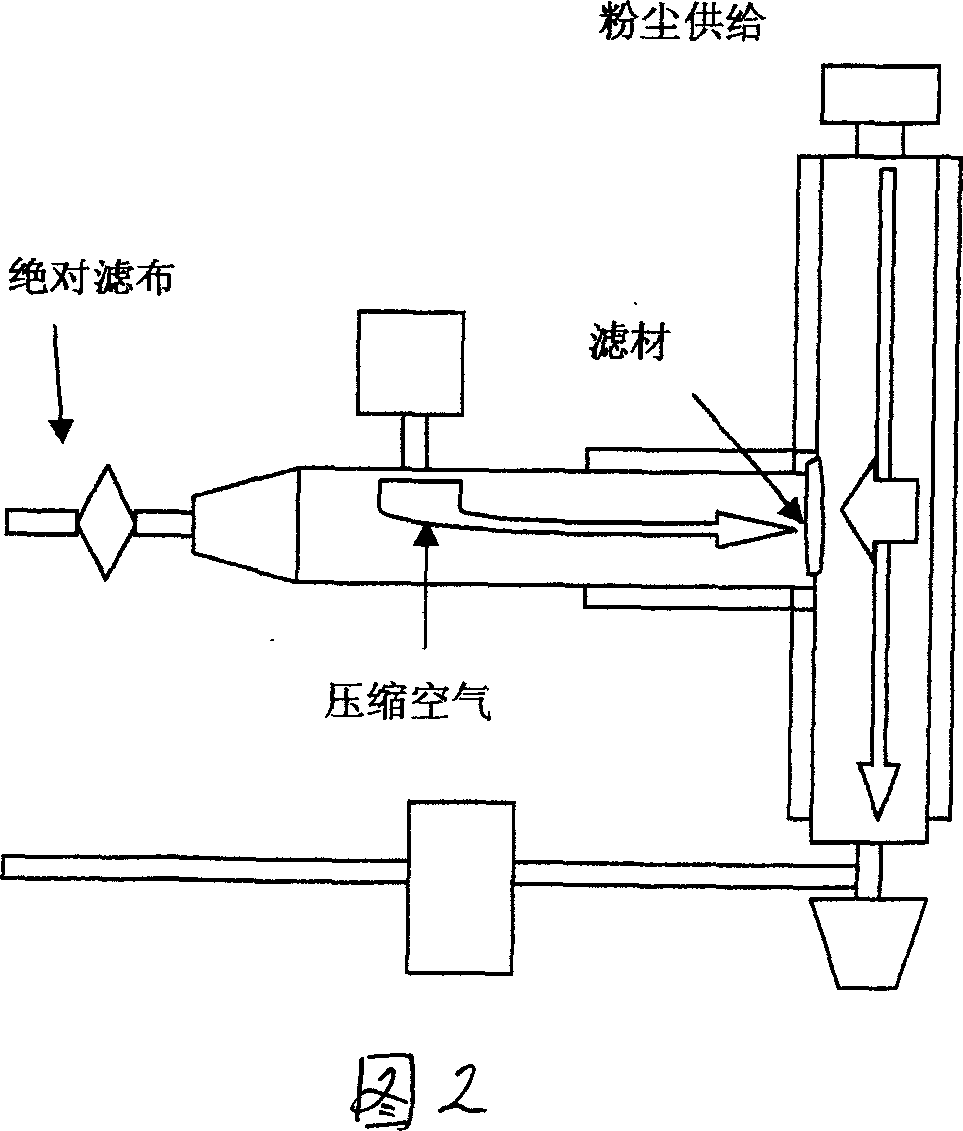

The present invention discloses one kind of heat resistant filter material and its use. The heat resistant filter material consists of one base material layer and one combined filter layers, the base material layer is made of inorganic fiber and / or heat resistant organic fiber, and at least one filter layer contains both inorganic fiber and heat resistant organic fiber, with the diameter of the inorganic fiber being smaller than that of the heat resistant organic fiber. The heat resistant filter material is used in filter. It has excellent complexing performance between the inorganic fiber and the heat resistant organic fiber, high dust collecting efficiency, high dust impact resistance, high antiwear performance, high heat shrinkage tolerance, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

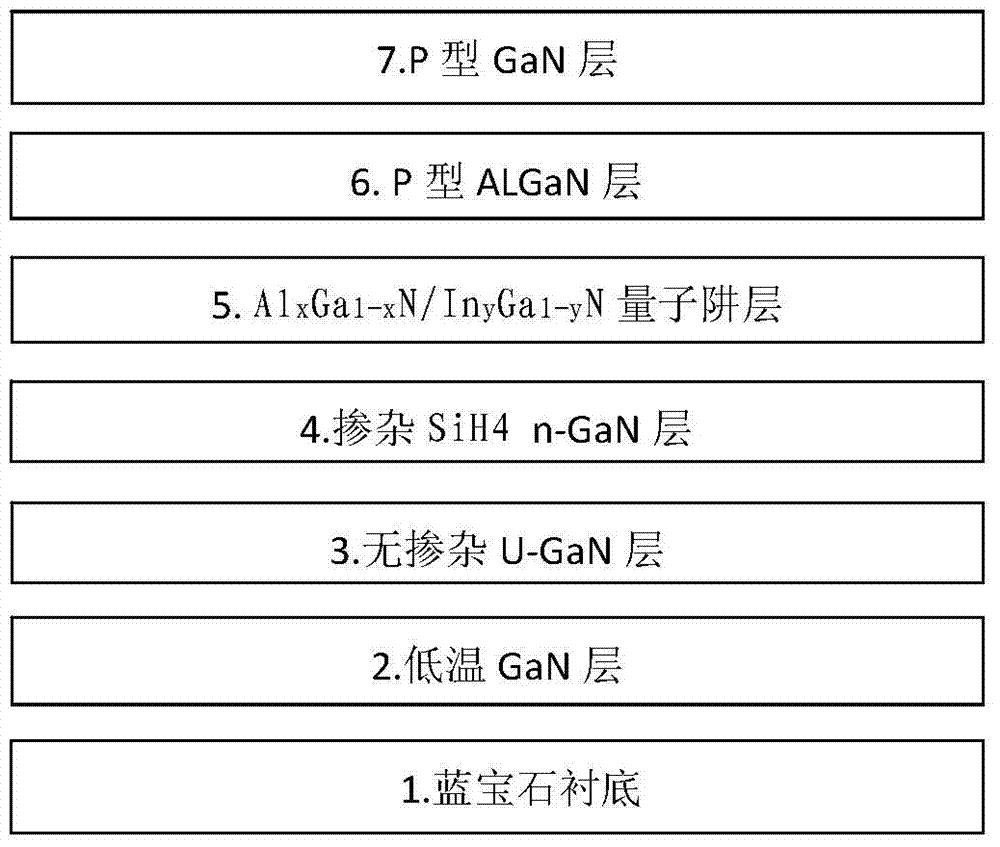

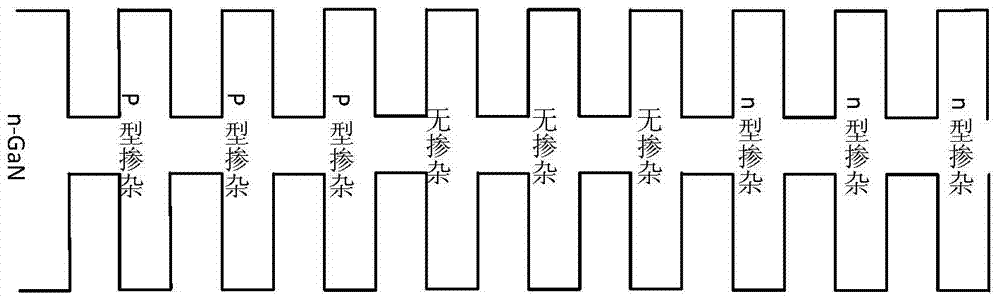

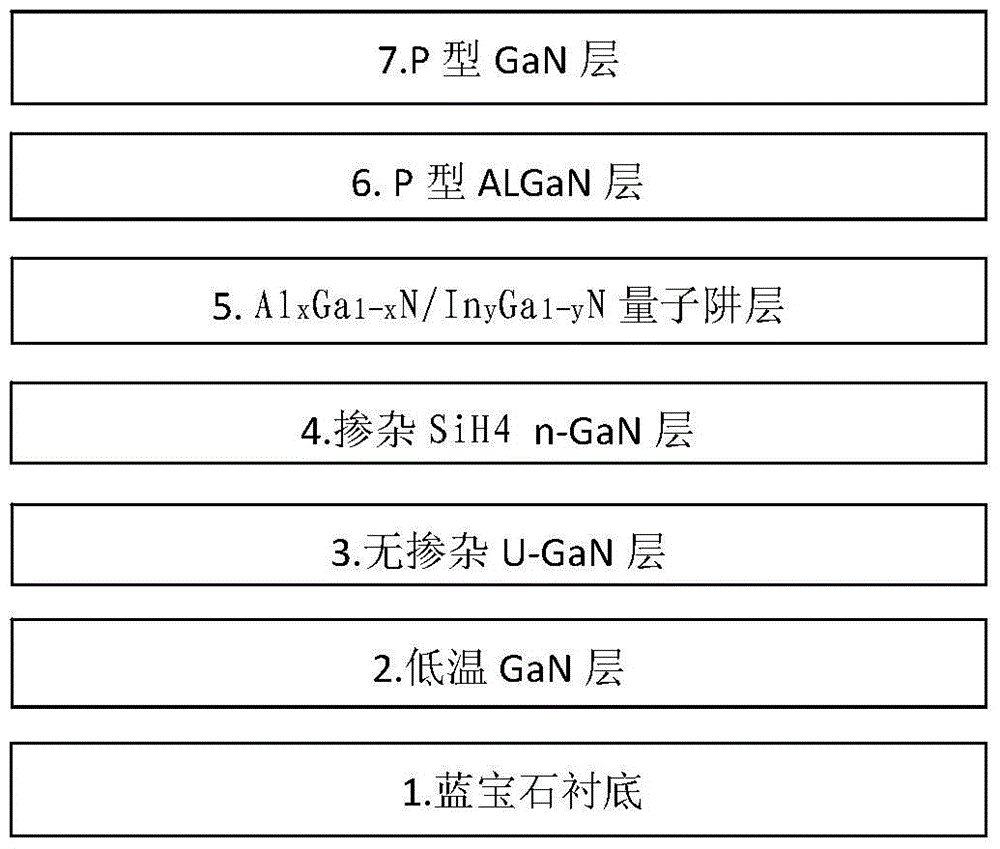

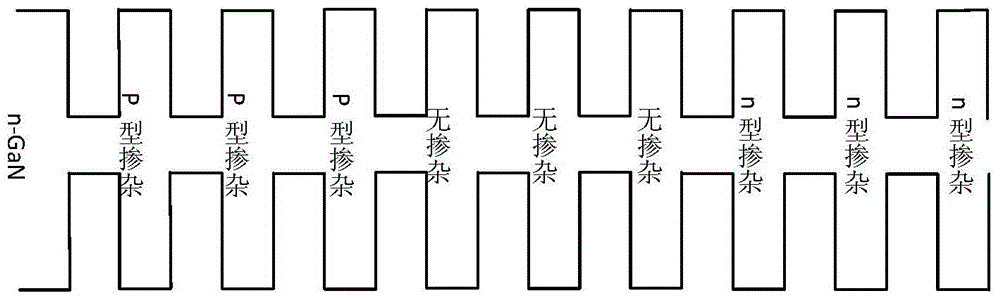

Epitaxial growth method for improving LED lighting efficiency

InactiveCN104332544AImprove luminous efficiencyComposite Luminous Efficiency DecreaseSemiconductor devicesQuantum wellP type doping

The invention provides a novel LED epitaxial growth method which can effectively improve the lighting efficiency of LED epitaxial structures. The method comprises the links of N-GaN layer growth, multi-quantum well layer growth and P-GaN layer growth, wherein the multi-quantum well layer is of a structure of a plurality of pairs of AlxGa <1-x> N / InyGa <1-y> N, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1; the multi-quantum well layer growth link includes three growth stages in sequence, wherein the AlxGa1-xN quantum barrier is subjected to p type doping in the first stage, the AlxGa1-xN quantum barrier is not doped in the second stage, and the AlxGa1-xN quantum barrier is subjected to n type doping in the third stage; a p type doped AlGaN stopping layer grows, and then the P-GaN layer growth link is performed.

Owner:西安利科光电科技有限公司

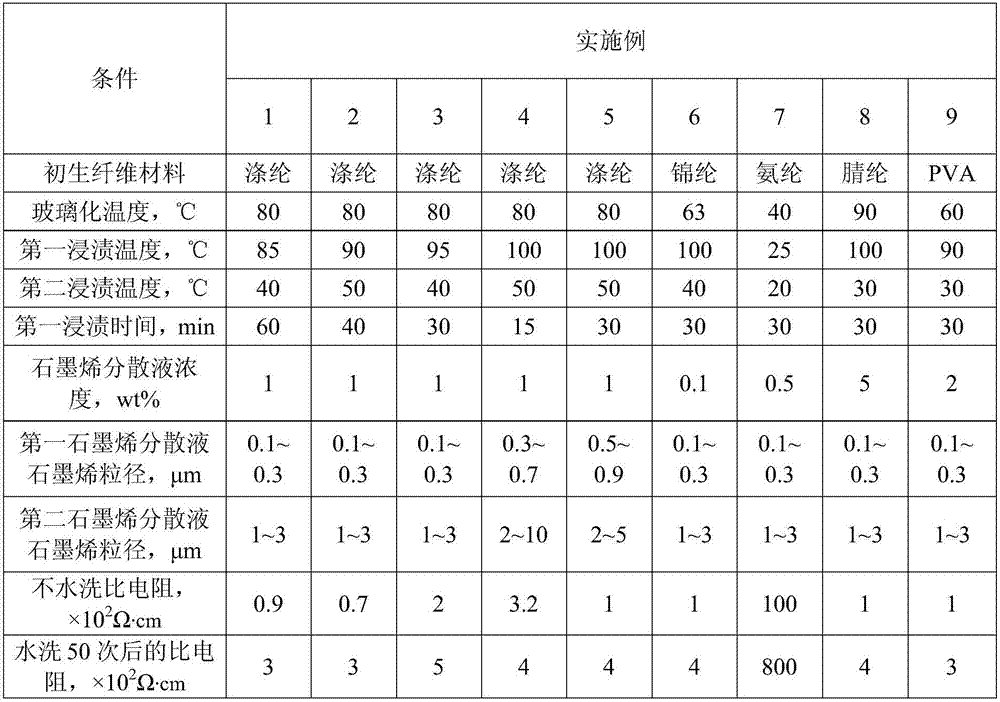

Composite fiber, preparation method and applications

The invention relates to a preparation method of composite fiber. The preparation method comprises the following steps: immersing nascent fiber in graphene substance dispersing solution and then cooling and drying to obtain composite fiber, wherein the range of immersing temperature is at high-elastic-state temperature of the nascent fiber material. By immersing nascent fiber into graphene substance dispersing solution at the high-elastic-state temperature, the compounding of the graphene substances inside and outside the fiber can be realized, and the evenness and firmness of the graphene substances in the fiber can be increased; the conductivity of the fiber can be enhanced by adding graphene and / or biomass graphene; the far infrared performance of the fiber can be further strengthened by adding graphene oxide and / and biomass graphene; and the graphene substances can be effectively added inside the fiber by adopting the preparation method, and the fiber is externally cladded with the graphene substances.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

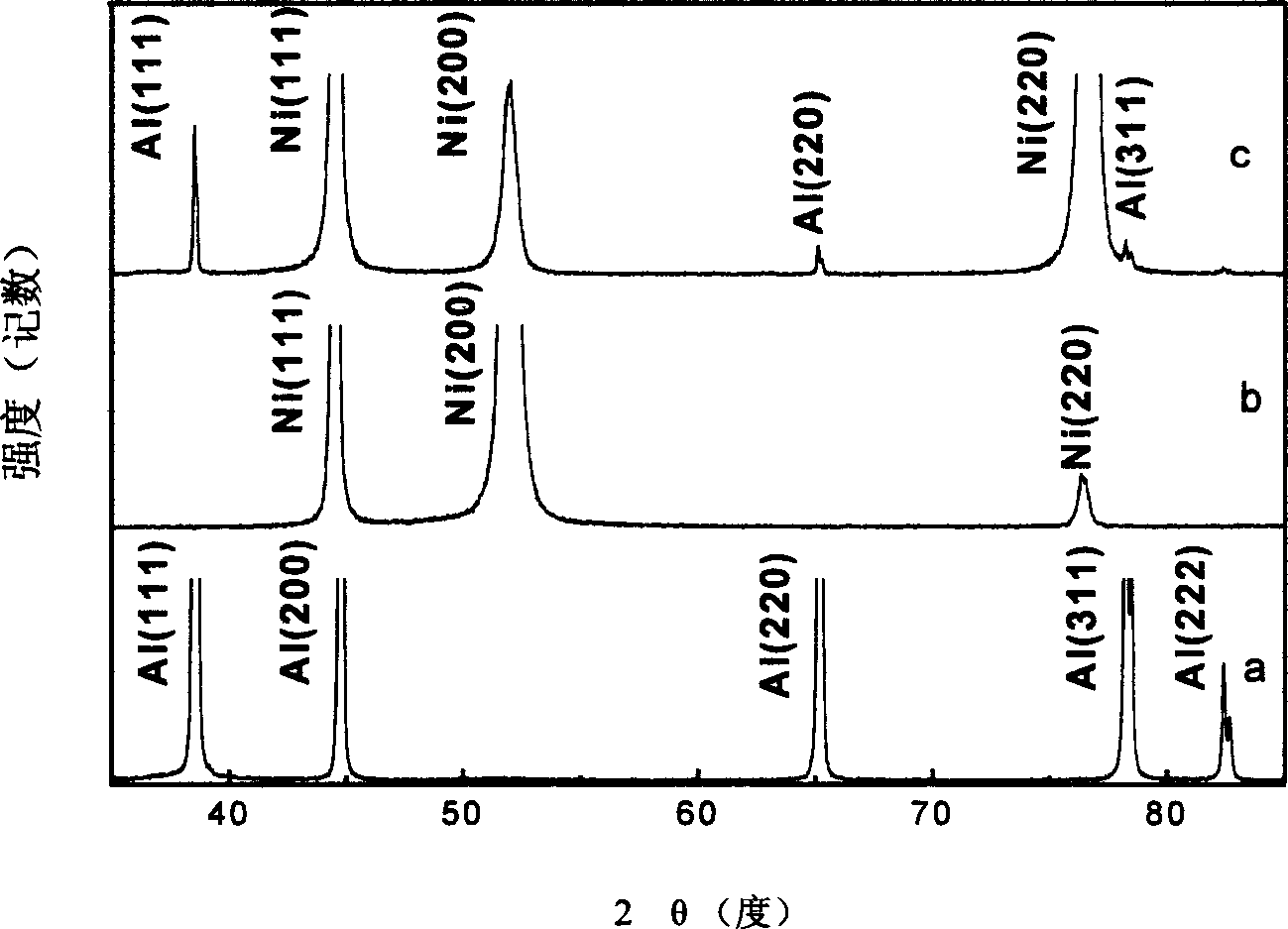

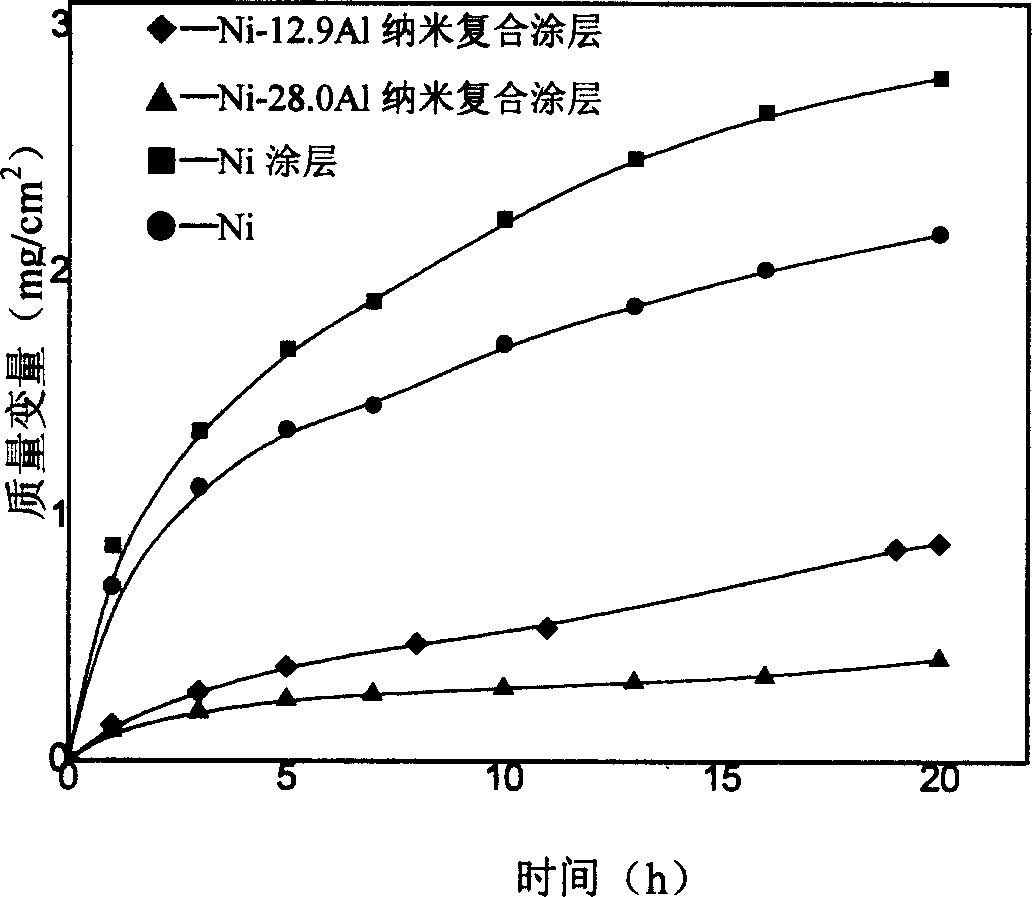

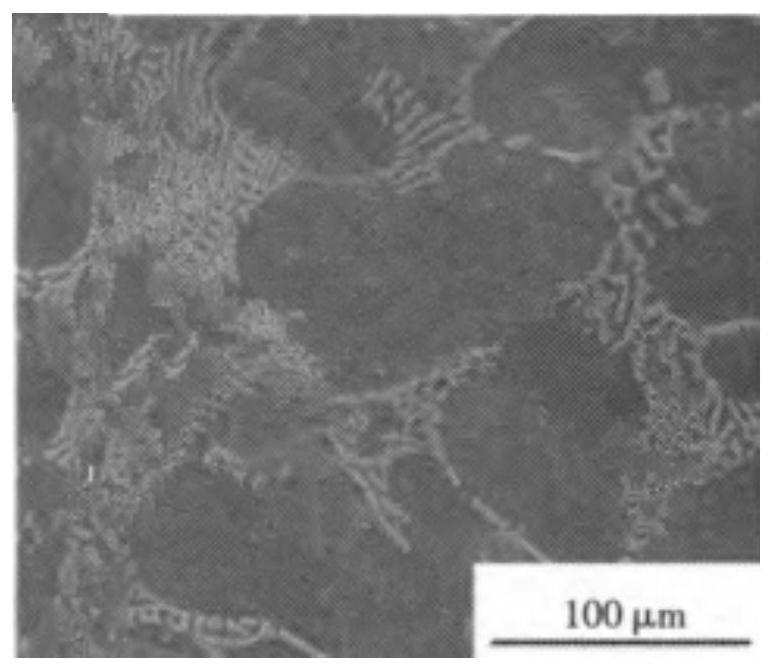

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

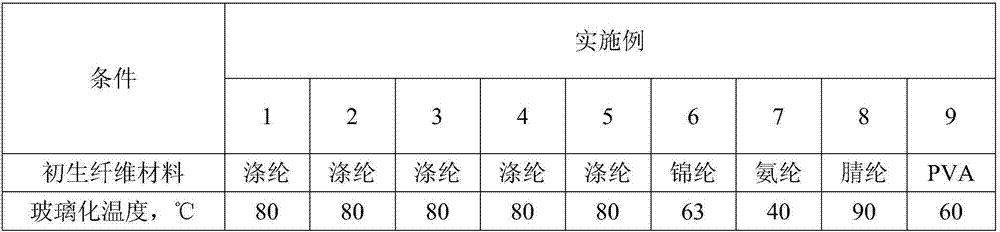

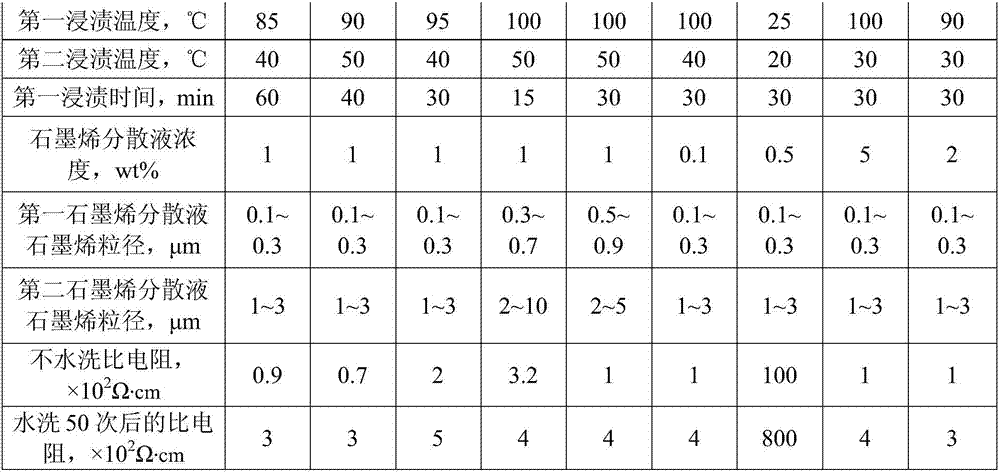

Composite fiber, preparation method and applications

InactiveCN106930099APromotes even distributionIncrease the amount of compoundingFibre typesWoven fabricsFiberGraphene

The invention relates to a preparation method of composite fiber. The preparation method comprises the following steps: (1) immersing nascent fiber in graphene substance dispersing solution with particle size of being less than 1mum for the first time, to obtain fiber immersed with graphene substances with the particle size of being less than 1mum; and (2) immersing the fiber immersed with graphene substances with the particle size of being less than 1mum, obtained in the step (1), into dispersing solution containing graphene substance with particle size of being less than 1-20mum for the second time, and then cooling and drying to obtain composite fiber, wherein the temperature of the secondary immersing is lower than that of the first-time immersing. The graphene substances inside the fiber are evenly distributed, especially are evenly distributed in longitudinal direction; the density of graphene is increased, and the conductivity of the fiber is enhanced; and the firmness of the graphene substances is increased, and the washability of the fiber is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

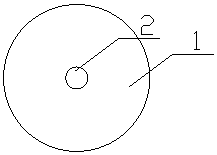

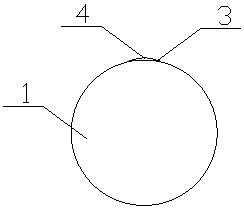

Phase change energy storage material carrier and method of phase change energy storage material carrier for packaging phase change material

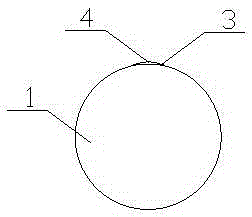

InactiveCN105300152AGive full play to the role of energy savingImprove thermal conductivityHeat storage plantsHeat exhanger sealing arrangementEngineeringPhase change

The invention provides a phase change energy storage material carrier and a method of the phase change energy storage material carrier for packaging a phase change energy storage material. A hollow metal material device is adopted to serve as the phase change energy storage material carrier, the periphery of the hollow metal material device is sealed, only one round hole feeding opening is formed in the top and sealed, and the packaging process is easy and convenient; in addition, the metal material device is hollow, and the phase change material compound quantity is high; the thermal conductivity of a metal material is good, and heat exchange can be better carried out, so that the energy conservation effect of the phase change energy storage material is better and sufficiently played, and the better energy storage and temperature adjusting effect is achieved.

Owner:SHENZHEN UNIV

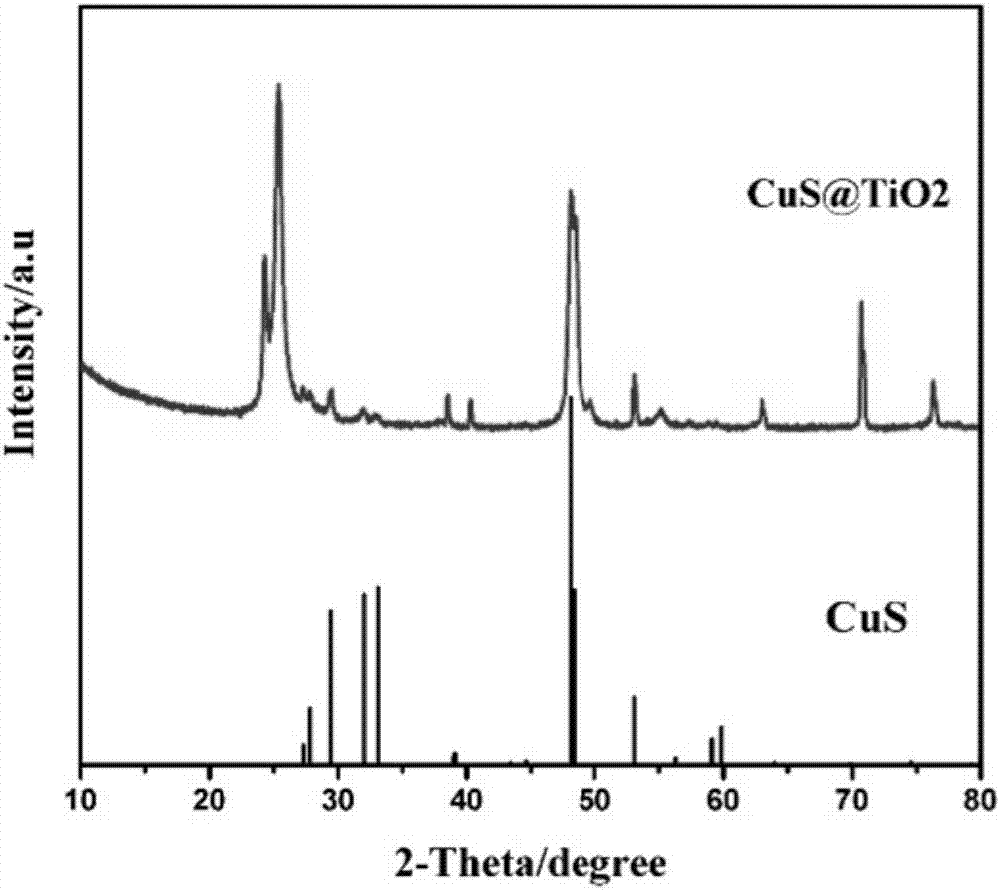

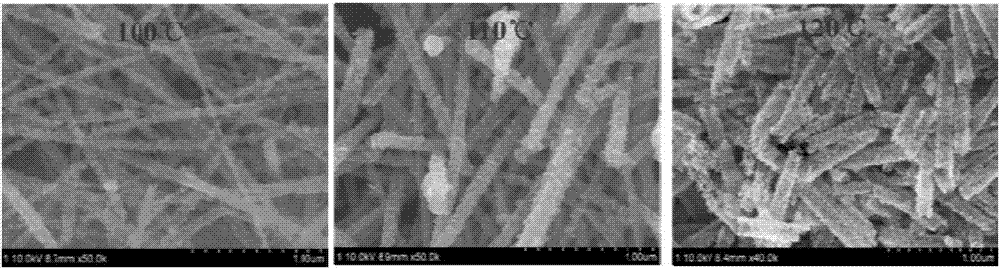

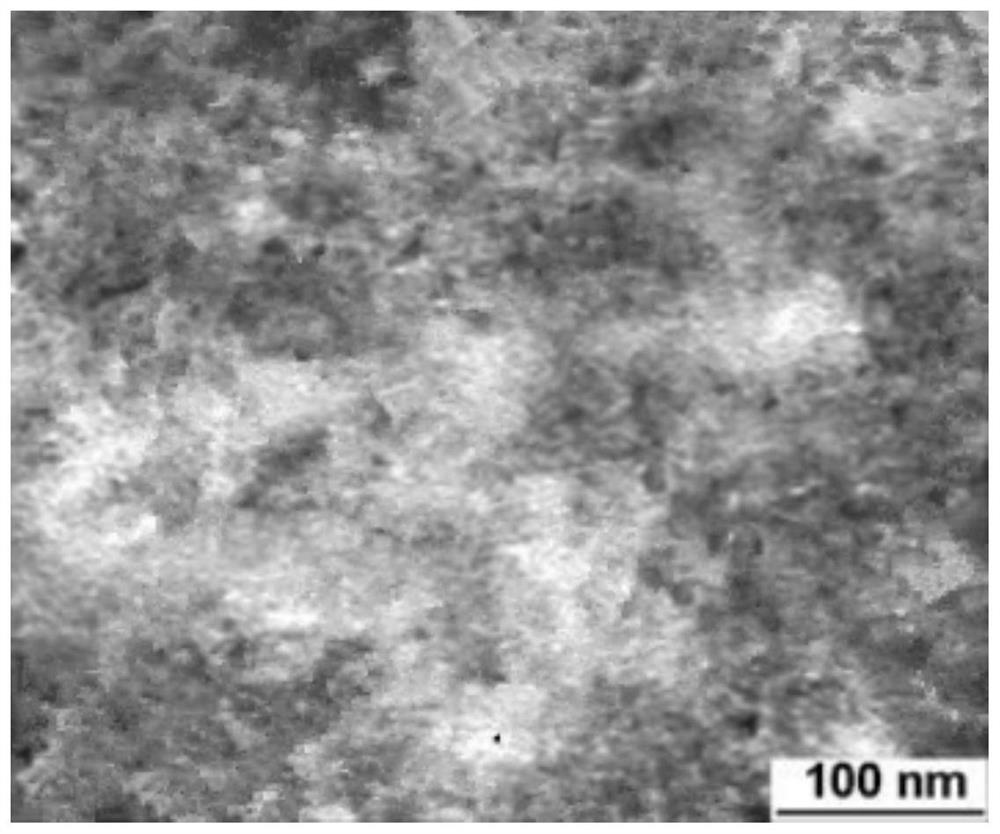

Nano titanium dioxide/copper sulphide nano composite material

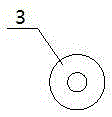

InactiveCN107051545AIncrease the amount of compoundingBroaden the range of light absorptionMaterial nanotechnologyPhysical/chemical process catalystsNanowireNano composites

The invention discloses a nano titanium dioxide / copper sulphide nano composite material. Titanium dioxide nanowires are prepared by a hydrothermal method and are used as a reaction substrate, a compound structure of copper sulphide nanosheets and titanium dioxide nanowires is prepared successfully by a secondary hydrothermal method under the conditions that the temperature is 100 DEG C and the reaction time is 10 hours, meanwhile, influence of hydrothermal temperature and hydrothermal time to photocatalytic performance of the composite structure is researched. Copper sulphide is prepared into a sheet structure, the compound quantity of the copper sulphide and the titanium dioxide nanowires is increased, the copper sulphide nanosheets and the titanium dioxide nanowires form a heterostructure, the light absorption range of titanium dioxide is expanded, and finally, the photocatalytic efficiency of the composite structure is improved. In the method, equipment is simple, process parameters are controllable, and the repeatability is high. The prepared nano composite material has important application in the field of photocatalysts.

Owner:ZHEJIANG SCI-TECH UNIV

Phase-change energy-storage concrete and manufacturing method thereof

The invention provides phase-change energy-storage concrete and a manufacturing method thereof. According to the manufacturing method, a hollow metal material device is used as a carrier of a phase-change energy-storage material, the periphery of the hollow metal material device is sealed, and a feeding hole is formed in the top of the hollow metal material device and only needs to be sealed, so that the packaging process is simple and convenient; furthermore, the metal material is hollow and high in compound quantity and thermal conductivity and can be used for preferably carrying out heat exchange, so that the energy-saving effect of the phase-change energy-storage material can be beneficially exerted, and relatively good energy storage and temperature regulation effects are achieved; a fastening device is arranged on the periphery of the metal material device, so that the surface roughness of the metal material device is enhanced, the interface adhesion between the phase-change energy-storage metal material device and hardened cement paste is improved, and the strength of the phase-change energy-storage concrete is improved. According to the phase-change energy-storage concrete and the manufacturing method, the application path of phase-change materials in the building energy-saving field is broadened, and technical support is provided for the popularization and the application of the phase-change energy-storage concrete.

Owner:SHENZHEN UNIV

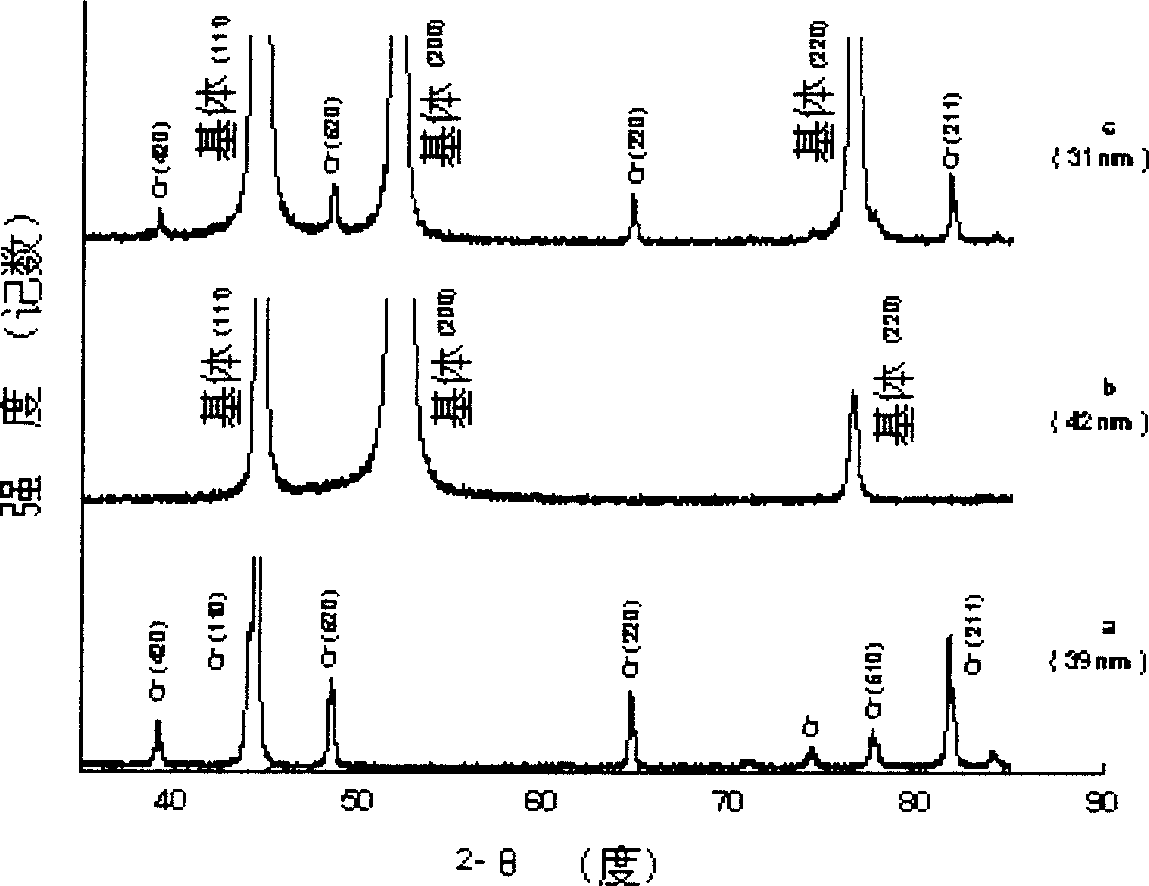

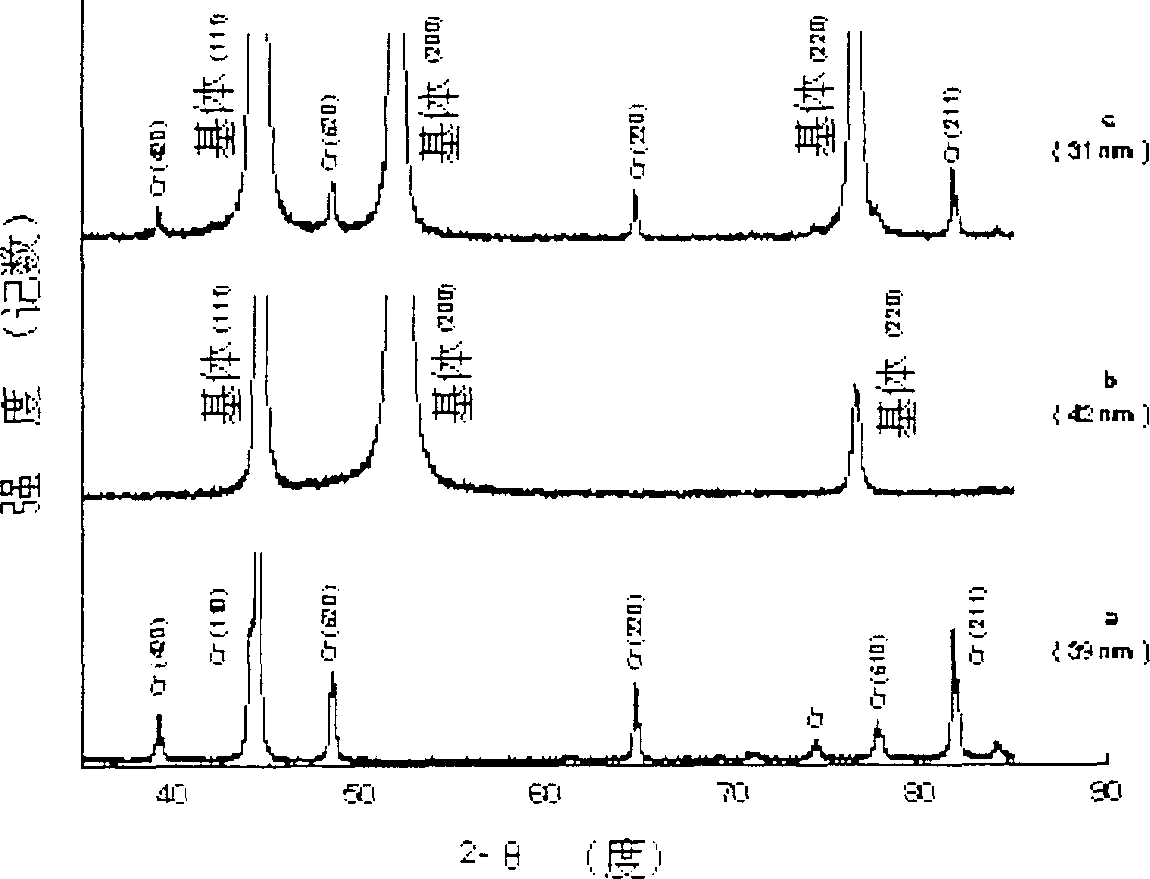

Thermal growth Cr203 film type M Cr nano composite plating and producing process and application

InactiveCN1576397AComposition controllableIncrease the amount of compoundingElectrolytic coatingsNanocrystalThermal growth

The thermally grown Cr2O3 film type M-Cr nano composite coating consists of nano crystal M coating and nano metal Cr grains dispersed in the coating, where M is Ni, Fe or Co. Of the nano metal Cr grain, the lowest content is 7.3-13 wt%, and the highest content is the maximum compounded amount, 25 wt% at present, and M is the rest. The nano composite Ni-Cr, Fe-Cr or Co-Cr coating is prepared through composite electroplating process to deposit metal M and Cr coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Cr2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

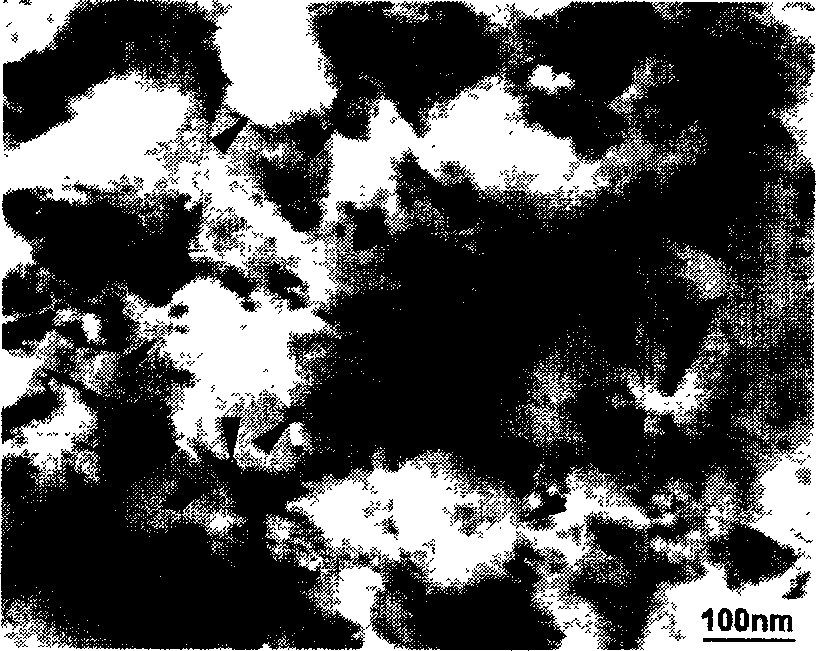

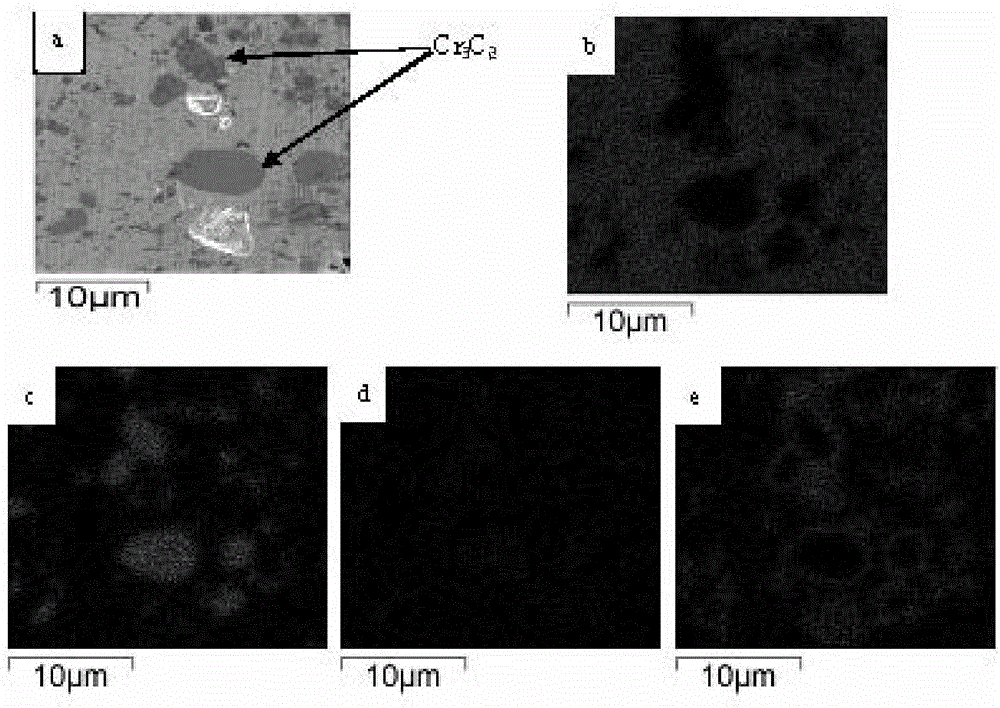

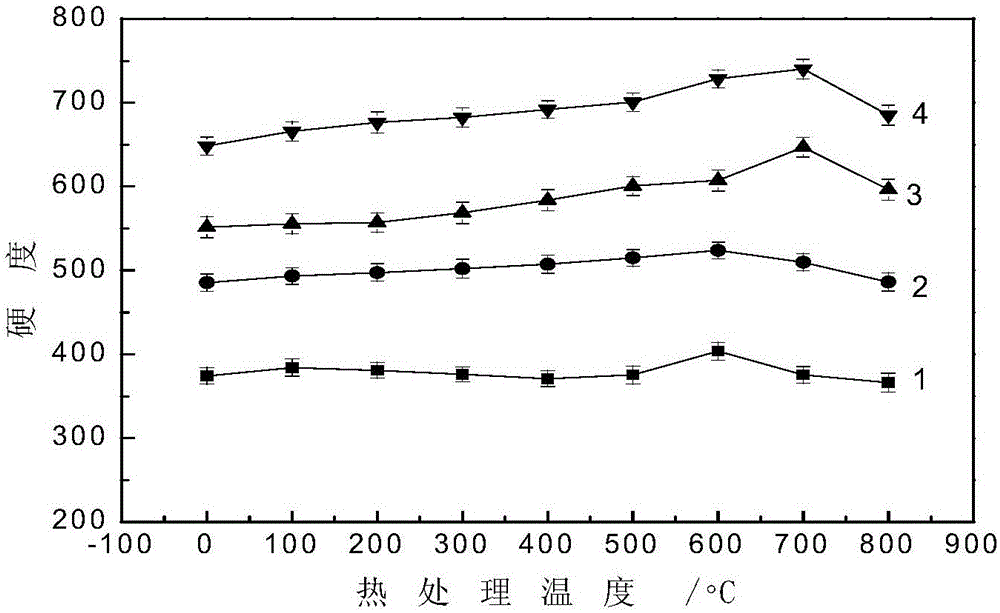

High-temperature-resistant composite coating and preparation method thereof

InactiveCN106283162AIncrease the compounding amount of particlesImprove performanceElectrolytic coatingsMetallic materialsRelative motion

The invention discloses a preparation method of a high-temperature-resistant composite coating. The composite coating employs cobalt as a base metal and nickel-covered chromium carbide particles as a disperse phase, and the chromium carbide particles of high content and uniform dispersion maintain high hardness of the composite coating at normal temperature and high temperature; composite coating liquid is dispersed by means of mechanical stirring and ultrasonic stirring to form uniform and stable composite coating liquid; electrodeposited base is a metal material, the surface of the base is pretreated, the metal Co and hard particles Cr3C2 are co-deposited into the composite coating by comprehensively controlling the process parameters such as electrodepositing temperature, current density, coating liquid flow and relative motion speed of cathode and anode. The problems that it is difficult to composite micro hard particles with high content in the composite electrodepositing process, the hard particles are unevenly distributed in the coating and the hard particles are in poor combination with the base metal Co are solved, and the prepared Co-Cr3C2 composite coating has high red hardness and excellent wear resistance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

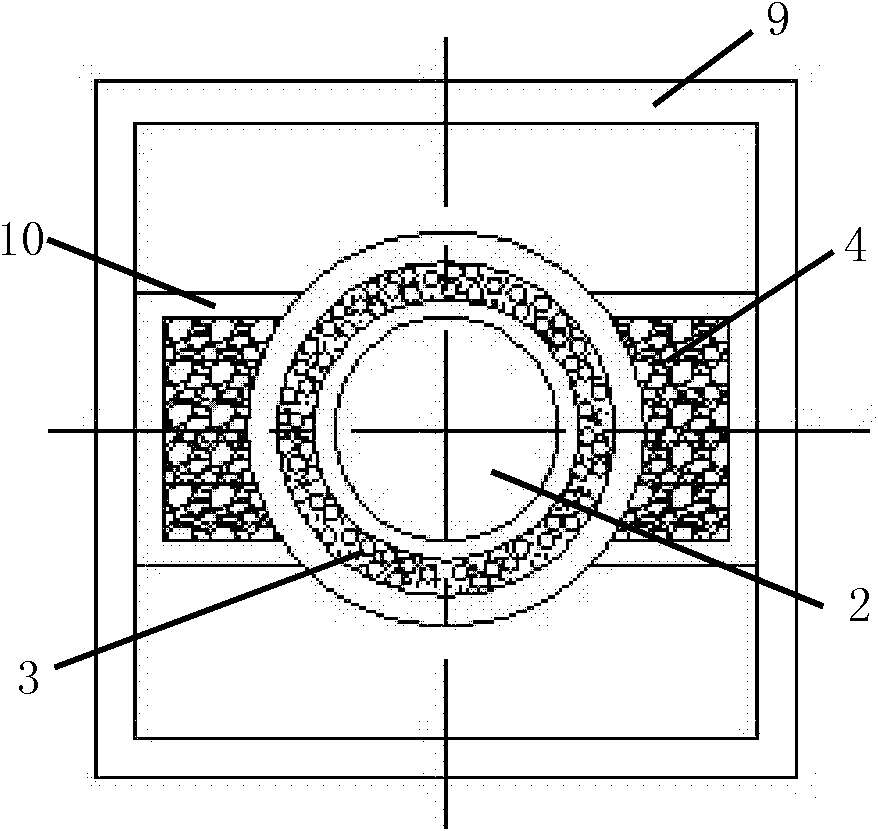

Method of increasing content of magnetic powder in magnesium alloy micro-arc oxidation membrane

InactiveCN104313665AImprove corrosion resistanceEmbodies electromagnetic wave absorptionAnodisationMicro arc oxidationElectrolysis

The invention relates to a preparation method of a magnesium alloy with corrosion resistance in the surface and a functional protective layer on the surface, in particular to a method of increasing content of magnetic powder in a magnesium alloy micro-arc oxidation membrane, belongs to the technical field of surface processing. The method comprises the following steps: putting a magnesium alloy matrix in an electrolytic bath with a magnet arranged at the bottom firstly, adding the magnetic powder in electrolyte in the electrolytic bath, enabling the magnetic powder to uniformly cover the electrolyte, then adopting a micro-arc oxidation method to compound a ceramic membrane on the surface of the magnesium alloy, and forming a composite micro-arc oxidation ceramic membrane which is uniformly covered by the magnetic powder on the surface of the magnesium alloy, wherein the composite membrane layer is capable of reducing the number of micropores and cracks on the surface of the micro-arc oxidation membrane layer and improving corrosion resistance of the magnesium alloy. According to the method disclosed by the invention, the micro-arc oxidation membrane is enabled to have a magnetic function, by virtue of the magnet arranged at the bottom of the outer side of the electrolytic bath, the magnetic powder enters the oxidation membrane through a micro-arc oxidation fusion and discharge channel under the effect of magnetism, so that compound quantity of the magnetic powder in the micro-arc oxidation membrane is increased, the micro-arc oxidation membrane can more reflect the functions of the magnetic powder of electromagnetic wave absorption and shielding, and the application field of the micro-arc oxidation coating is widened.

Owner:SHENYANG LIGONG UNIV

Cyanide-free silver-based composite plating solution, silver-based composite plating layer and preparation method thereof

ActiveCN111235608AImprove stabilityImprove anti-interference abilityElectrolytic coatingsCyanideActive agent

The invention discloses a cyanide-free silver-based composite plating solution, a silver-based composite plating layer and a preparation method of the silver-based composite plating layer. The cyanide-free silver-based composite plating solution comprises silver nitrate, a multicomponent complexing agent, conductive salt, a buffering agent, a cationic surfactant, an additive and micro-nano particles; the multielement complexing agent takes triethylenetetramine or / and soluble salt thereof as a main complexing agent, and takes one or more of triethylenetetramine hexaacetic acid or triethylenetetramine hexaacetic acid salt, ethylenediaminetetraacetic acid or ethylenediaminetetraacetic acid salt, and citric acid or citrate as an auxiliary complexing agent; the concentration of the silver nitrate is 0.1-0.7 mol / L, the concentration ratio of the main complexing agent to the silver nitrate is 1-6:1, the concentration of the auxiliary complexing agent is 0.05-1 mol / L, the concentration of theconductive salt is 0.2-1.2 mol / L, the concentration of the cationic surfactant is 0.0005-0.003 mol / L, and the buffering agent is used for the pH value of the cyanide-free silver-based composite plating solution to be 1-7. The cyanide-free silver-based composite plating solution is stable, and the prepared silver-based composite plating layer has the functions of friction reduction and wear resistance and has good compactness.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

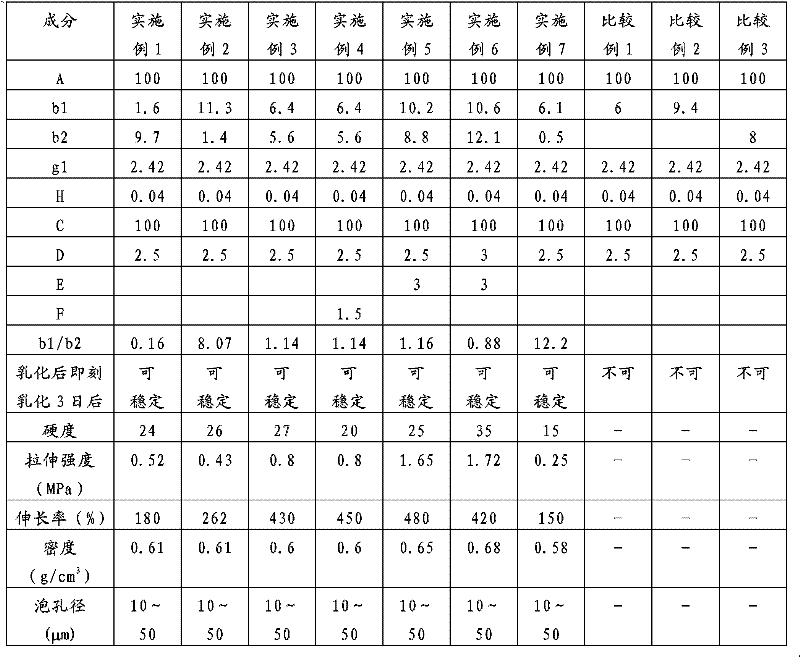

Silicone rubber sponge-forming emulsion composition and method for producing silicone rubber sponge

Provided is a silicone rubber sponge-forming emulsion composition for which the emulsion stability does not drop when the amount of reinforcing silica filler is increased, for which the cell shape of a sponge does not become defective, and for which the hardness is not too high; and further provided is a method for manufacturing a silicone rubber sponge from the aforementioned composition. This silicone rubber sponge-forming emulsion composition is comprised of: (A) 100 parts by weight of a liquid diorganopolysiloxane having at least two silicon atom-bonding alkenyl groups within one molecule; (B) 1-50 parts by weight of a reinforcing silica filler comprised of (b1) fumed silica and (b2) precipitation method silica (with the (b1) / (b2) weight ratio being 0.01 / 1-30 / 1); (C) 50-250 parts by weight of water containing (c) smectite clay; (D) 0.1-7 parts by weight of sorbitan fatty acid ester; (E) 0-10 parts by weight of isononanoic acid ester; (F) 0-10 parts by weight of Guerbet alcohol; and (G) an amount of curing agent sufficient to cross-link and harden component (A). This method manufactures a silicone rubber sponge by hardening said composition while heating and dehydrating the same, or by heating and hardening the same and then dehydrating the resulting silicone rubber-like hardened object in the wet state.

Owner:DOW CORNING TORAY CO LTD

Absorbable bone graft material and preparation method thereof

InactiveCN105879117AReduce allergic reactionsIncrease the amount of compoundingTissue regenerationProsthesisHaversian canalReagent

The invention provides an absorbable bone graft material and a preparation method thereof, belonging to the field of preparation of ergonomic materials. The invention prepares BCB and BMP compositely to form a resorbable bone graft material by optimizing and adjusting the dosage of reagents and processing time in the preparation process. The BCB prepared by the present invention has no fat cells, bone cells, blood vessels and nerves in the central tube, protein components of the bone matrix, and Harvard tubes, and the composite bone graft material has no allergic reaction and is easily biodegradable, which overcomes the prior art Implant materials are prone to allergic reactions and are not easy to degrade, so they are suitable for large-scale clinical use.

Owner:TIANJIN ZHONGJIN BIOLOGICAL DEV CO LTD

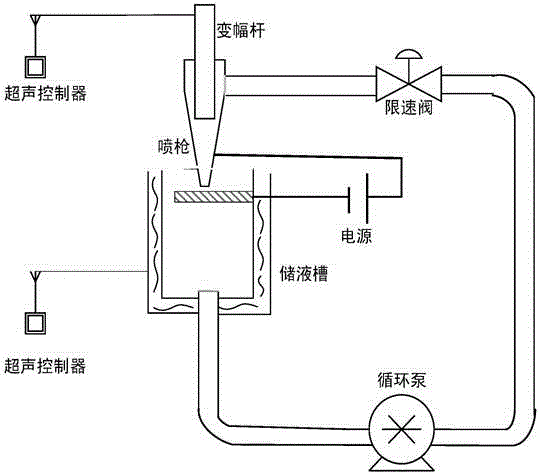

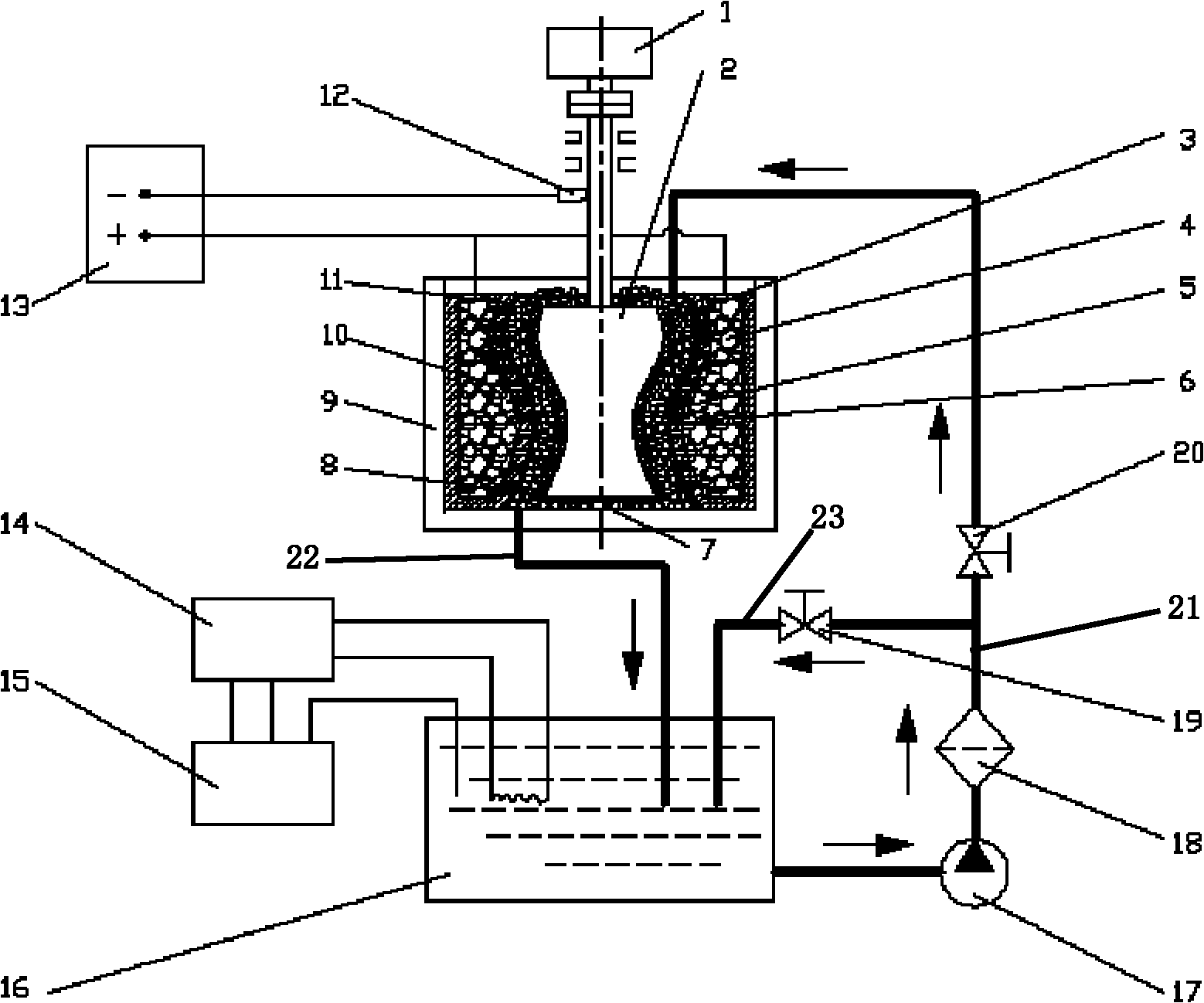

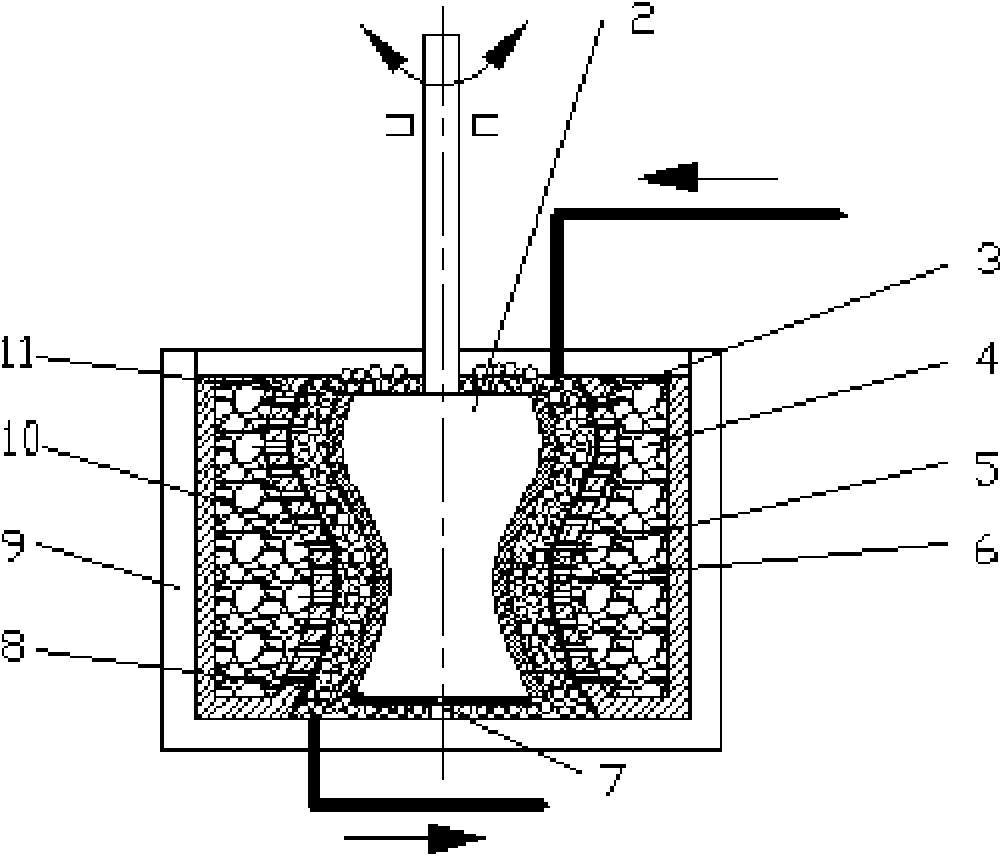

Deposition process for improving compound quantity of nanoparticles in electric deposition

InactiveCN102162117AEvenly dispersedUniform and dense tissueElectrolytic coatingsElectrodesNanoparticleDeposition process

The invention discloses a deposition process for improving the compound quantity of nanoparticles in an electric deposition procedure. A mandrel used as a cathode and a first-phase metal electrode used as an anode are respectively put into a plating solution; the first-phase metal electrode used as a soluble anode is positioned in an annular anode basket; a plurality of through holes are formed at the inner side of the annular anode basket; the first-phase metal electrode is composed of a plurality of first-phase metal cakes; the plurality of first-phase metal cakes are put into the anode basket; a plurality of non-conductive hard particles are placed between the inner side of the anode basket and the mandrel; the diameter of each first-phase metal cake and the diameter of each non-conductive hard particle are greater than the diameter of each through hole; second-phase nanoparticles are mixed in the plating solution; and the mandrel makes a spinning motion. The invention greatly improves the compound quantity of nanoparticles in a compound electroformed layer, and greatly improves the fatigue strength, wear resistance and corrosion resistance of the compound electroformed layer.

Owner:SUZHOU VOCATIONAL UNIV

Polyethylene talcum powder master batch

The invention discloses a polyethylene talcum powder master batch. The polyethylene talcum powder master batch is prepared from, by weight, 19.5-20.5% of polyethylene, 0.1-1.1% of polyethylene wax and 78.9-79.9% of talcum powder. During preparation, talcum powder is put at first, polyethylene is added, then, the polyethylene wax is added, the mixture is subjected to smelting to be heated to 150 min, heating is performed for 12 min, then, the mixture enters a double-screw extruder to be mixed, mixing is performed, and then extruding, cooling and grain dicing are performed. In this way, the polyethylene talcum powder master batch is applicable to plastic modification, and due to the compact form and the higher compound quantity, the plastic is good in dispersity, resistant to wear and scraping, capable of achieving feeding easily and good in heat stability.

Owner:苏州优矿塑新材料股份有限公司

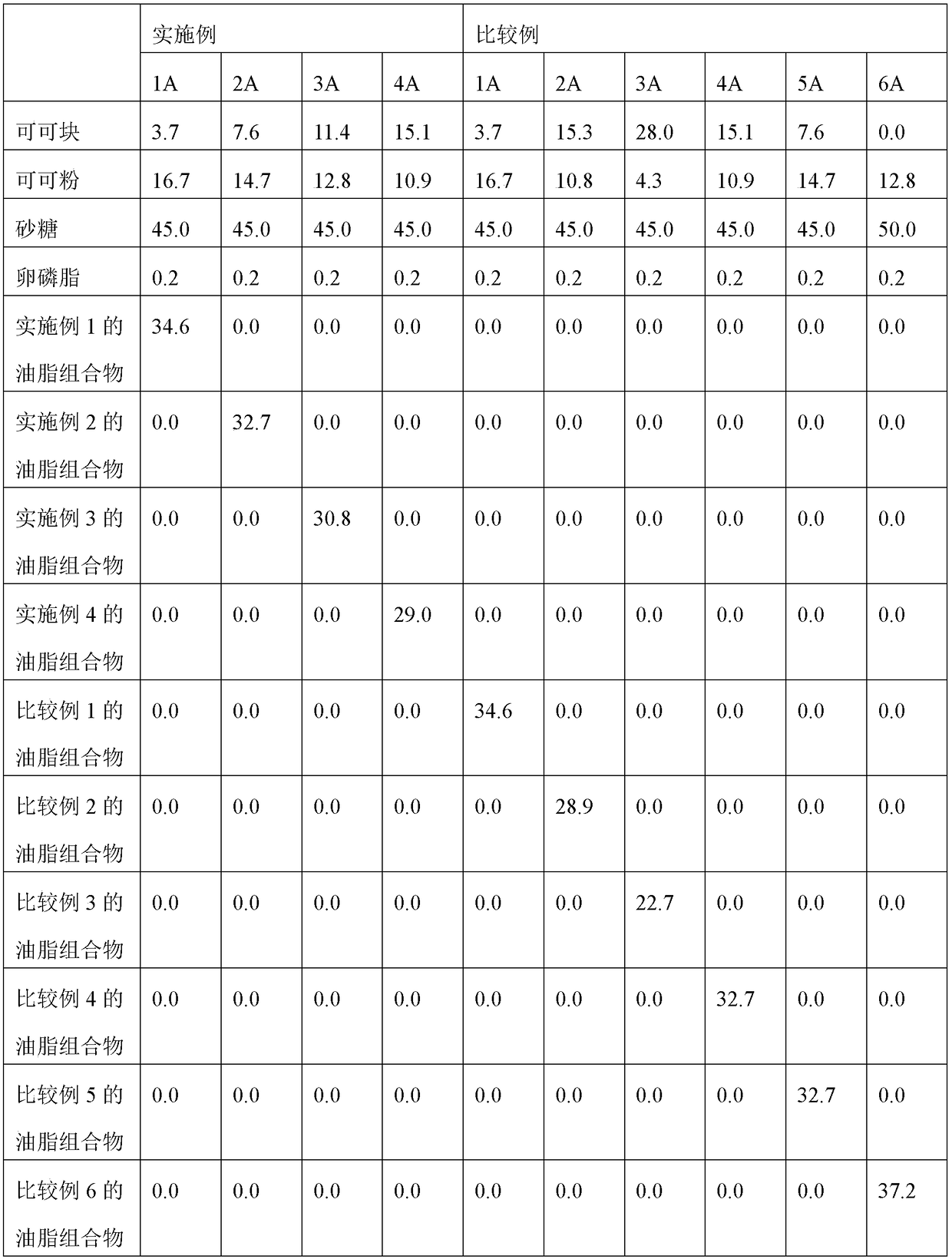

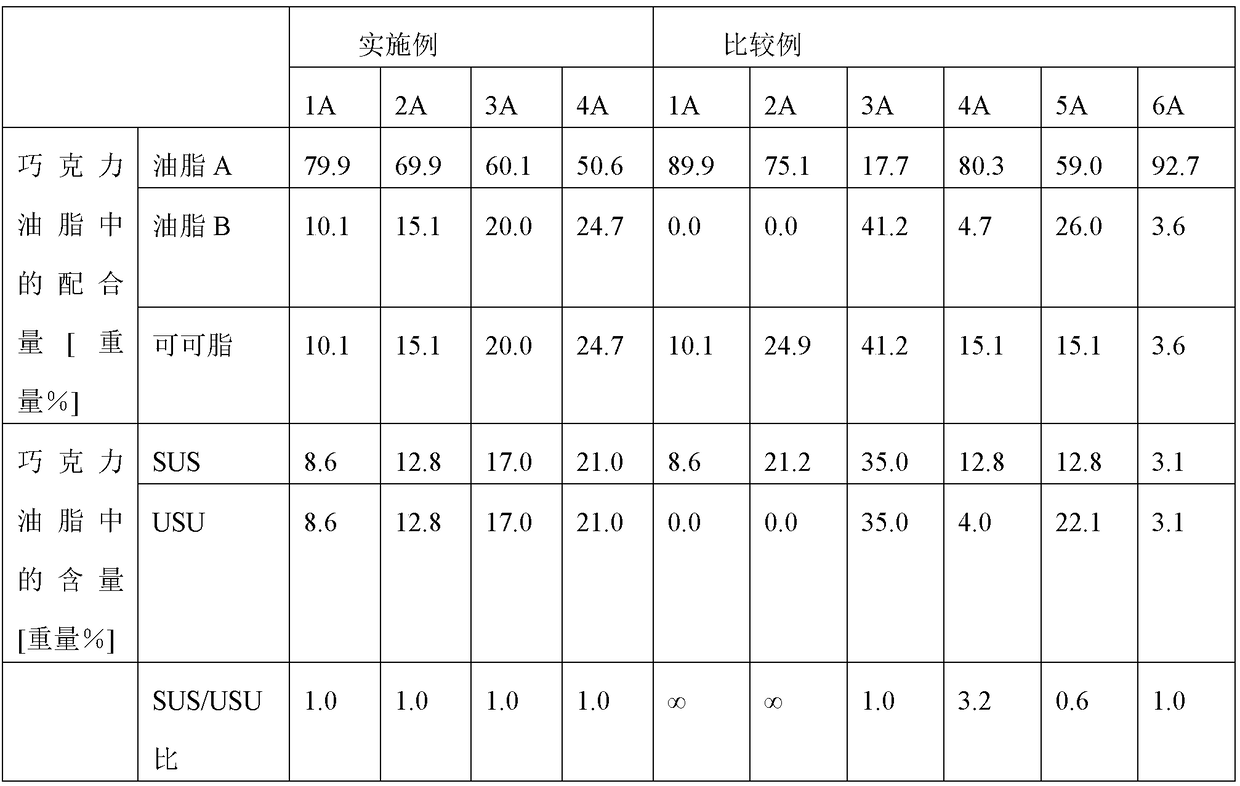

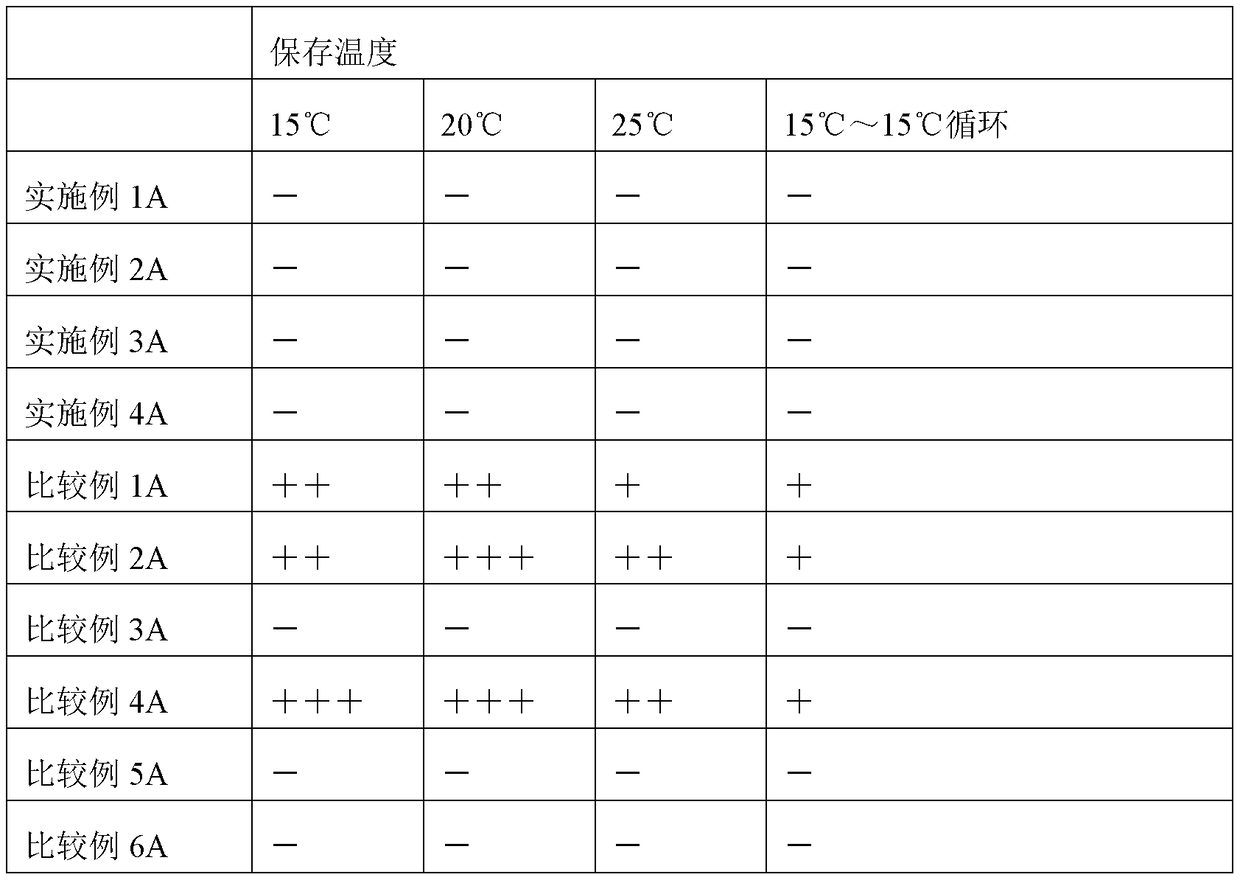

Oil or fat composition for lauric chocolates, and chocolate containing same

InactiveCN108882720AFast curingExcellent mold releaseFatty acid esterificationFatty-oils/fats separationButter cocoaHigh concentration

The present invention addresses the problem of providing an oil or fat for non-tempering chocolates, which enables the blending of cocoa butter at a high concentration in a lauric non-tempering chocolate, has heat resistance at such a level that the oil or fat can withstand the distribution at ambient temperature, has good gloss, luster, feeling upon eating, flavor and the like, and does not undergo the occurrence of blooming or change in hardness over time. An oil or fat containing an USU-type triglyceride is added at a proper content to a lauric hard butter. In this manner, the blending of cocoa butter at a high concentration into a chocolate prepared using a lauric hard butter, which is never before possible, becomes possible.

Owner:FUJI OIL CO LTD

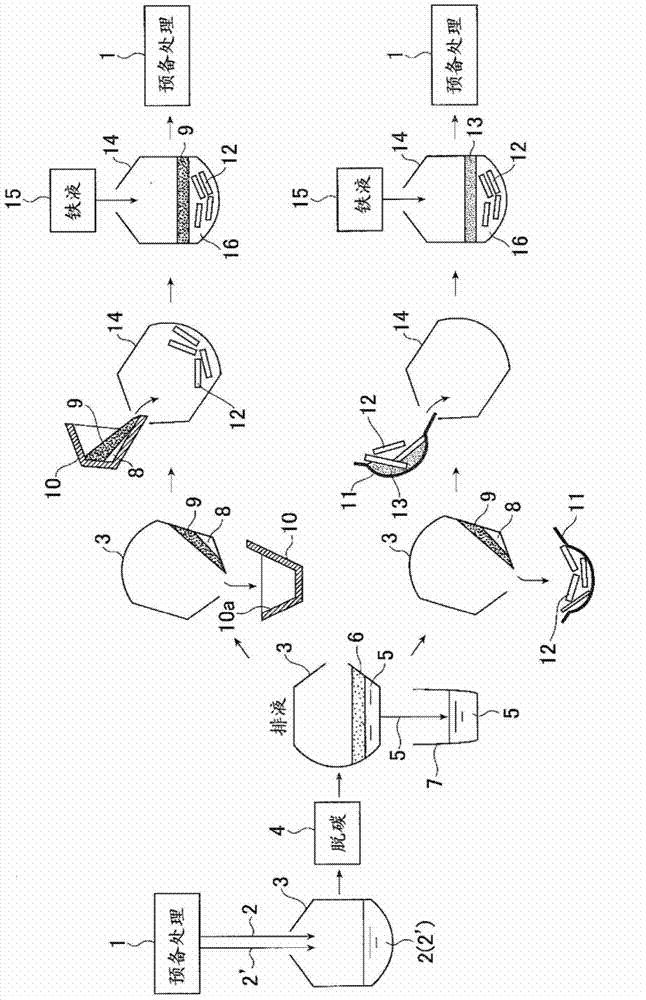

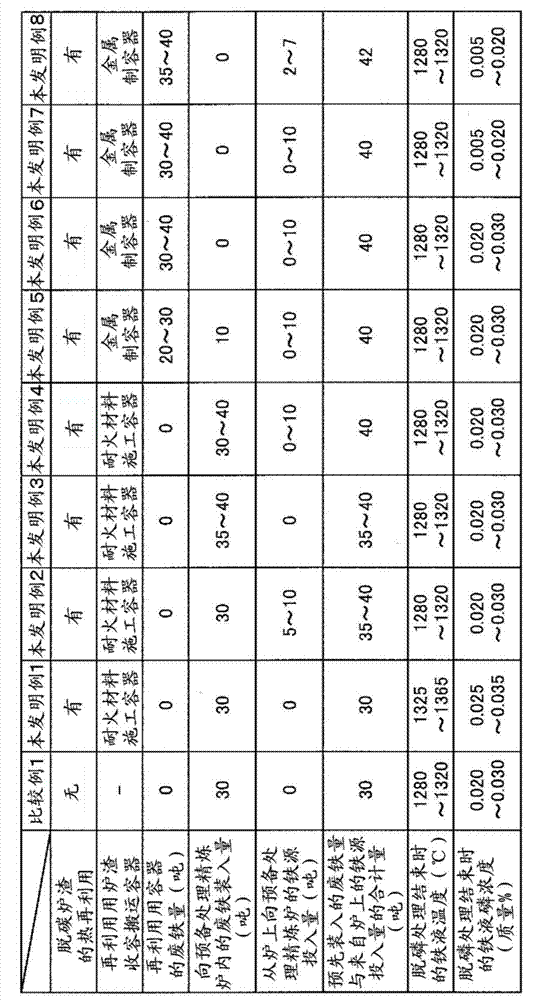

Refine method of hot metal

ActiveCN104769136AIncrease the amount of compoundingImprove yieldMetal recyclingManufacturing convertersScrapDecarburization

When manufacturing molten steel from hot metal using a two base converter-type refining furnace and using one as a hot metal pretreatment refining furnace and the other as a hot metal decarburization refining furnace, the molten slag generated in the decarburization refining furnace is used while still hot as a refining agent in the pretreatment refining furnace without compromising the productivities of the two refining furnaces. A refining method for manufacturing molten steel from hot metal using a converter-type refining furnace with at least two bases and using one as a hot metal pretreatment refining furnace (14) and using the other as a decarburization refining furnace (3) for the hot metal (2) pretreated in the pretreatment refining furnace. After the molten steel (5) obtained by decarburization refining in the decarburization refining furnace has been tapped in a ladle (7), the slag (9) remaining inside the decarburization refining furnace is allowed to flow down, still in the molten state, from above stacked iron scraps to solidify at least a portion of the slag. Then in pretreatment of hot metal in the pretreatment refining furnace, the slag, at least a portion of which has been solidified, is used together with the iron scraps while still hot.

Owner:JFE STEEL CORP

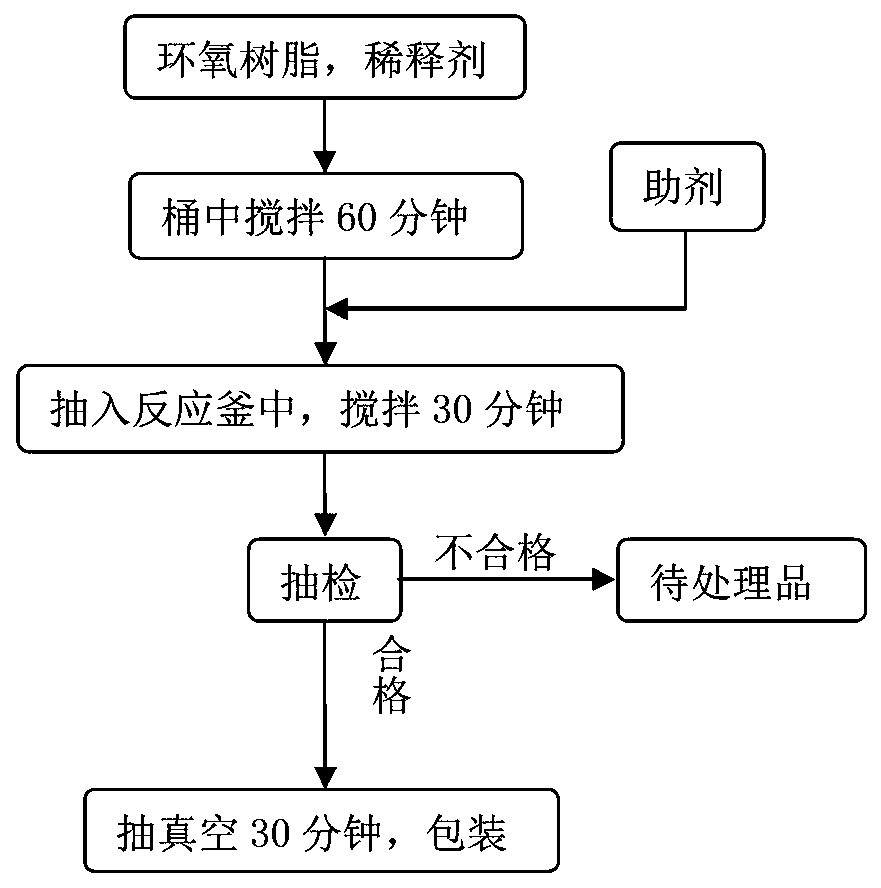

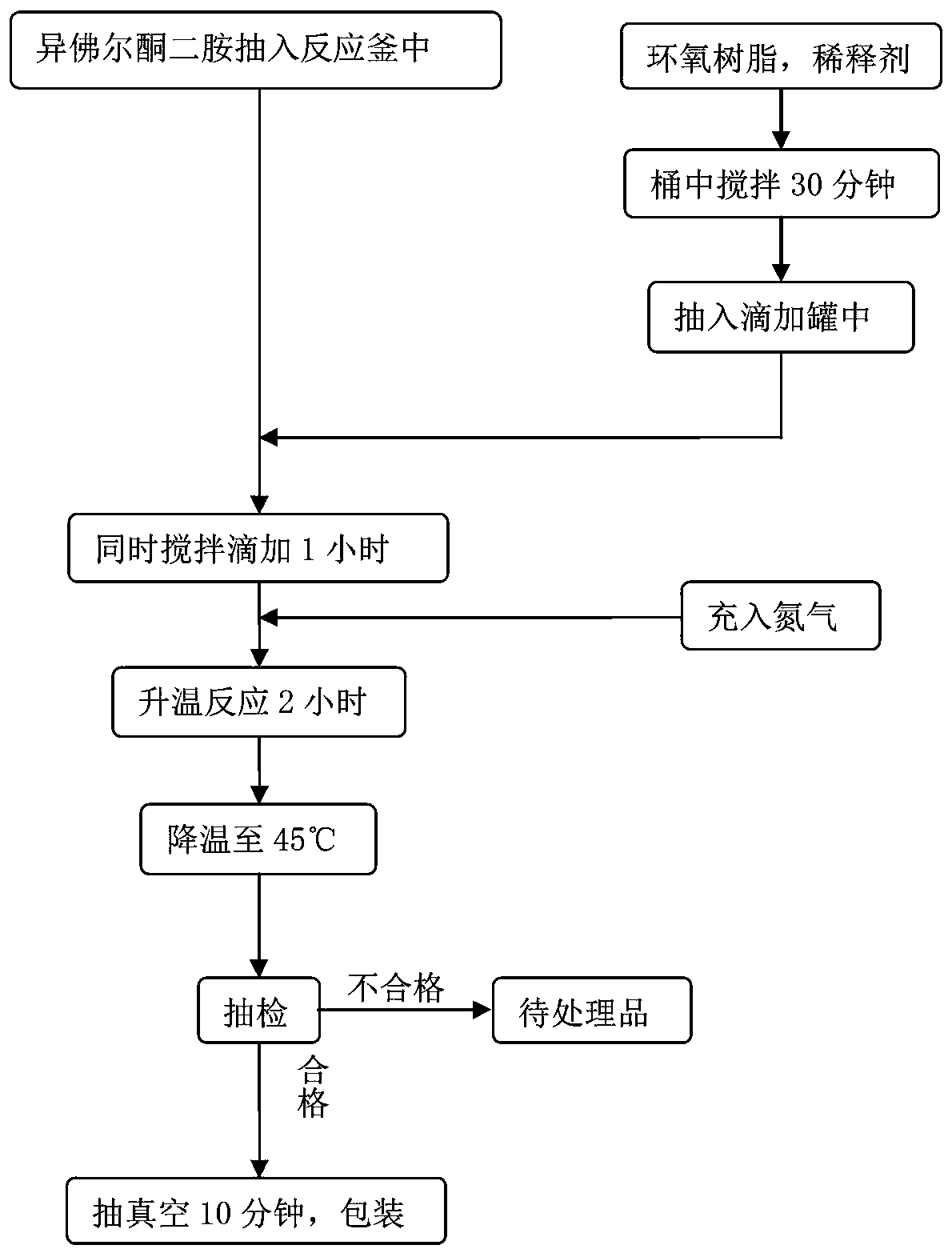

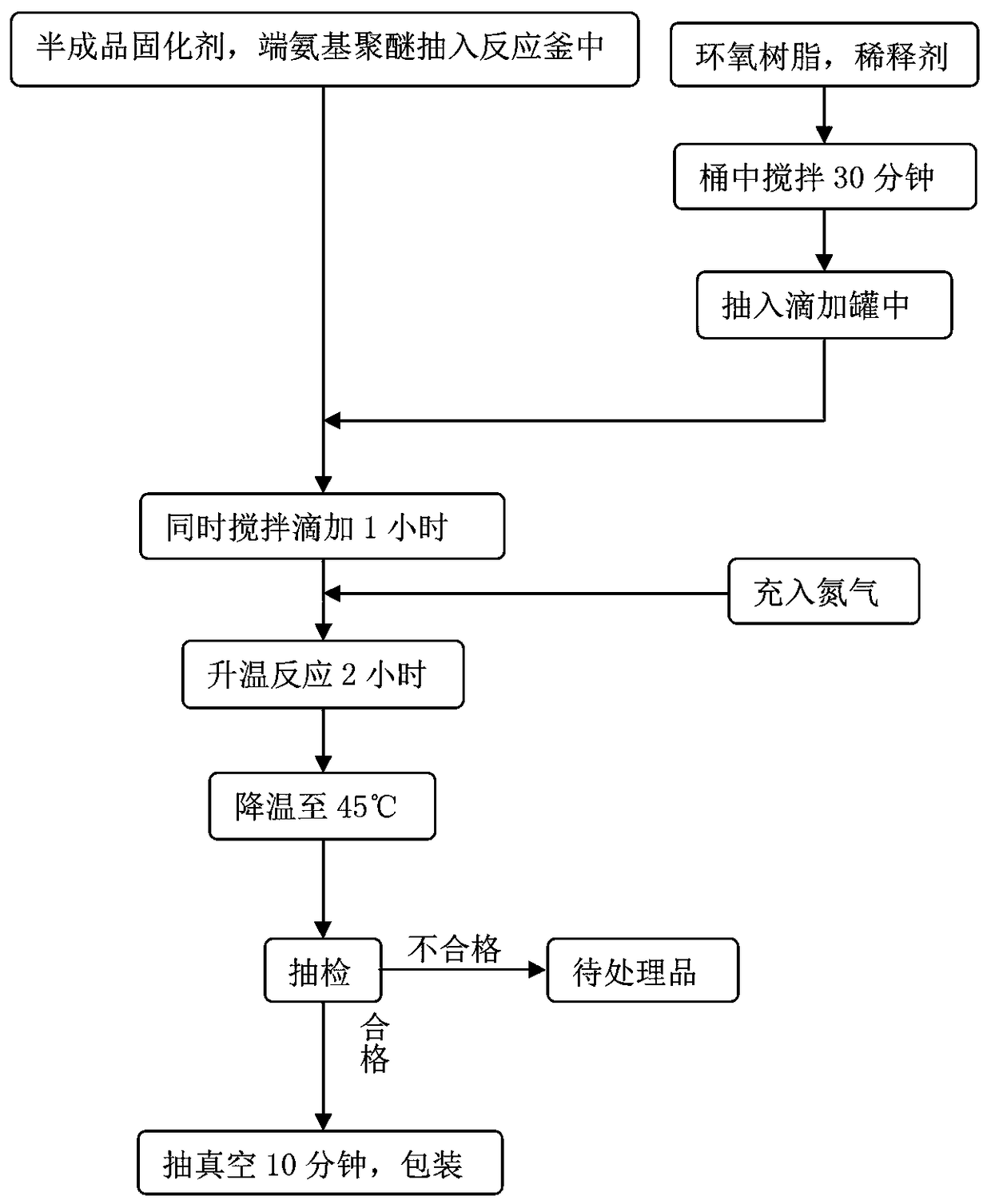

Preparation method of bi-component epoxy resin adhesive

InactiveCN109370498AReduce viscosityImprove operational convenienceEpoxy resin adhesivesEpoxyDiluent

The invention discloses a preparation method of a bi-component epoxy resin adhesive. The bi-component epoxy resin adhesive is prepared from an adhesive A and an adhesive B, wherein the adhesive A is prepared from 89 parts of epoxy resin, 10 parts of a diluent and 1 part of an assistant, the adhesive B is prepared through the steps that 1, a semi-finished product curing agent is firstly produced and contains 16 parts of epoxy resin, 42 parts of a diluent and 42 parts of isophorone diamine; wherein 2, 71.5 parts of semi-finished product curing agent, 8.5 parts of epoxy resin, 10 parts of diluentand 10 parts of amine-terminated polyether are adopted, wherein the bi-component epoxy resin adhesive is prepared according to the ratio 1 to 1 of the adhesive A to the adhesive B.

Owner:深圳市劲华电子材料有限公司

Composite resin particles and manufacturing method thereof

A project of the invention provides composite resin particles and a manufacturing method thereof. Through the composite resin particles, a foamed particle molded article which has good internal fusion, compression rigidity and flexibility resistance, and which can be protected from being broken due to deformation is obtained. The foamed particle molded article has less styrene monomer left, has good foaming ability during foaming, and has excellent forming property during forming. The project is solved by providing composite resin particles (1) taking a composite resin which is made by impregnating a polystyrene monomer in an ethylene resin as a basic resin and a manufacturing method of the composite resin particles (1). The composite resin comprises 100-900 parts by mass of a structural unit deriving from a styrene monomer based on 100 parts by mass of the ethylene resin. The content of the styrene monomer existing as a monomer in the composite resin particles is 0-500 ppm by mass. The ratio WXY of a xylene insoluble component in the composite resin particles (1) is 0-40% by mass. During manufacturing of the composite resin particles, two polymerization initiators with different 10 h half-life period temperatures are adopted.

Owner:JSP CORP

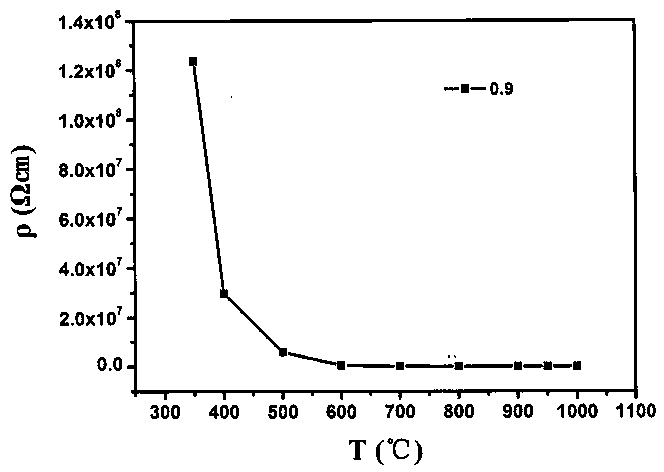

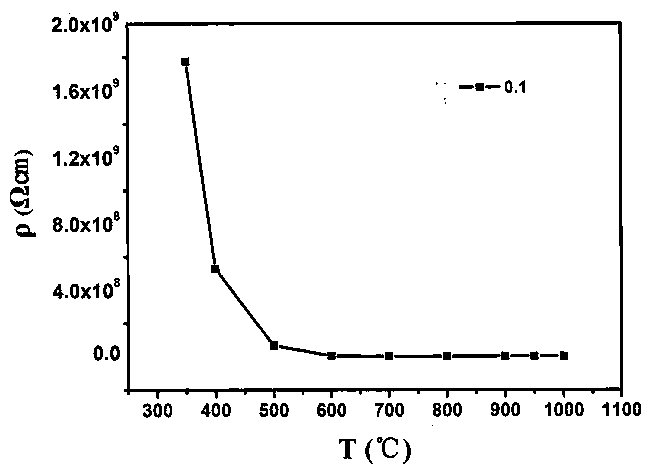

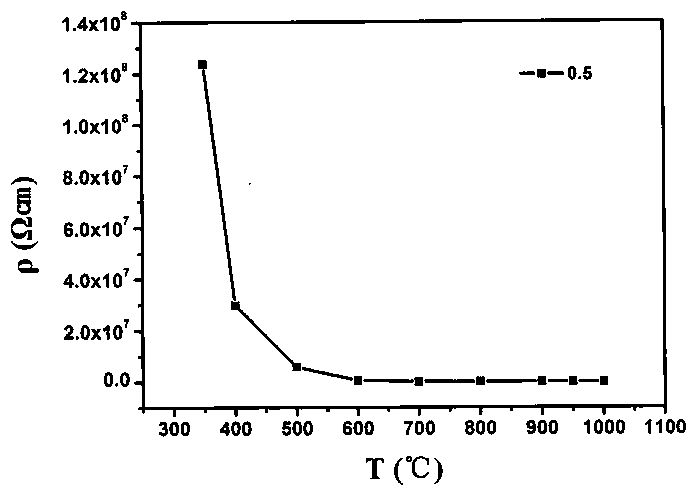

Bismuth titanate based perovskite phase thermosensitive ceramic composite material as well as preparation method and application thereof

ActiveCN108863350ASmall and uniform grainsHigh densityNegative temperature coefficient thermistorsCeramic compositeBismuth titanate

The invention relates to a bismuth titanate based perovskite phase thermosensitive ceramic composite material as well as a preparation method and application thereof. The material takes metal salt asa raw material, and xNa0.5Bi0.5TiO3-(1-x)Zn0.5Bi0.5TiO3 powder is prepared by adopting a Pechini method, wherein x is greater than 0 and less than 1; the powder is subjected to a processing process ofdrying, pre-firing, grinding, pre-pressing and molding, carrying out cold isostatic pressing and sintering to prepare the bismuth titanate based perovskite phase thermosensitive ceramic composite material. The material has the advantages of small and uniform crystal grains and good density; the material has an obvious negative temperature coefficient property in a temprature range of 350 to 900 DEG C; an electric property research results shows that when the compounding amount of bismuth titanate is increased, the resistance value of the ceramic material is increased and the B value is reduced, so that the material is a novel thermosensitive ceramic material which is applicable to temperature measurement and temperature control of a high-temperature region.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

A kind of phase change energy storage concrete and its manufacturing method

The invention provides phase-change energy-storage concrete and a manufacturing method thereof. According to the manufacturing method, a hollow metal material device is used as a carrier of a phase-change energy-storage material, the periphery of the hollow metal material device is sealed, and a feeding hole is formed in the top of the hollow metal material device and only needs to be sealed, so that the packaging process is simple and convenient; furthermore, the metal material is hollow and high in compound quantity and thermal conductivity and can be used for preferably carrying out heat exchange, so that the energy-saving effect of the phase-change energy-storage material can be beneficially exerted, and relatively good energy storage and temperature regulation effects are achieved; a fastening device is arranged on the periphery of the metal material device, so that the surface roughness of the metal material device is enhanced, the interface adhesion between the phase-change energy-storage metal material device and hardened cement paste is improved, and the strength of the phase-change energy-storage concrete is improved. According to the phase-change energy-storage concrete and the manufacturing method, the application path of phase-change materials in the building energy-saving field is broadened, and technical support is provided for the popularization and the application of the phase-change energy-storage concrete.

Owner:SHENZHEN UNIV

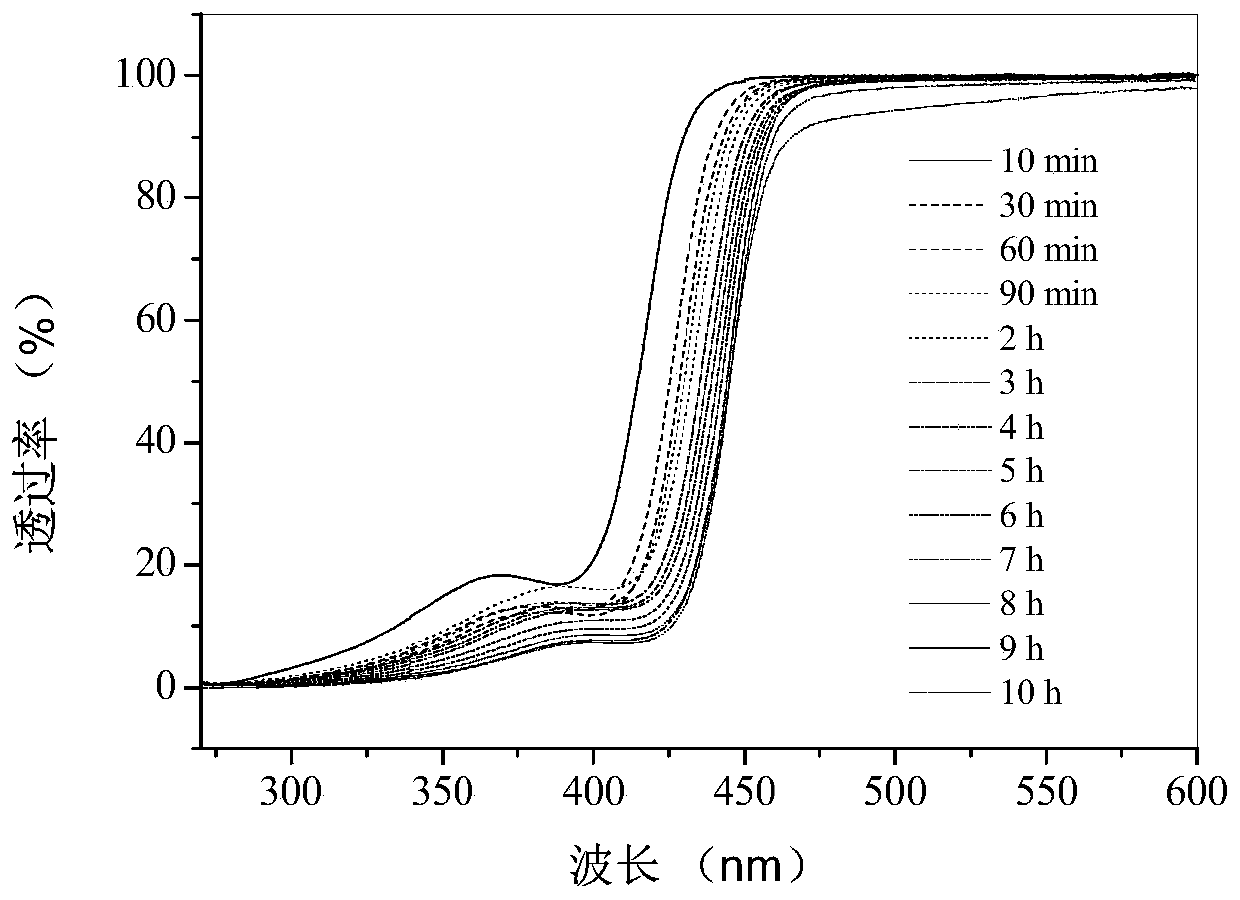

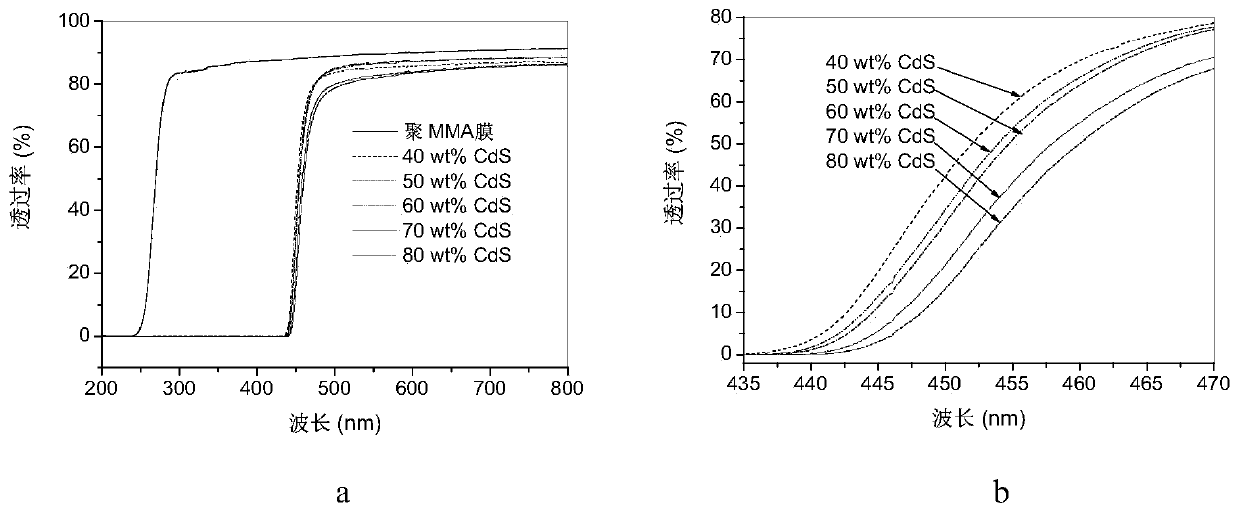

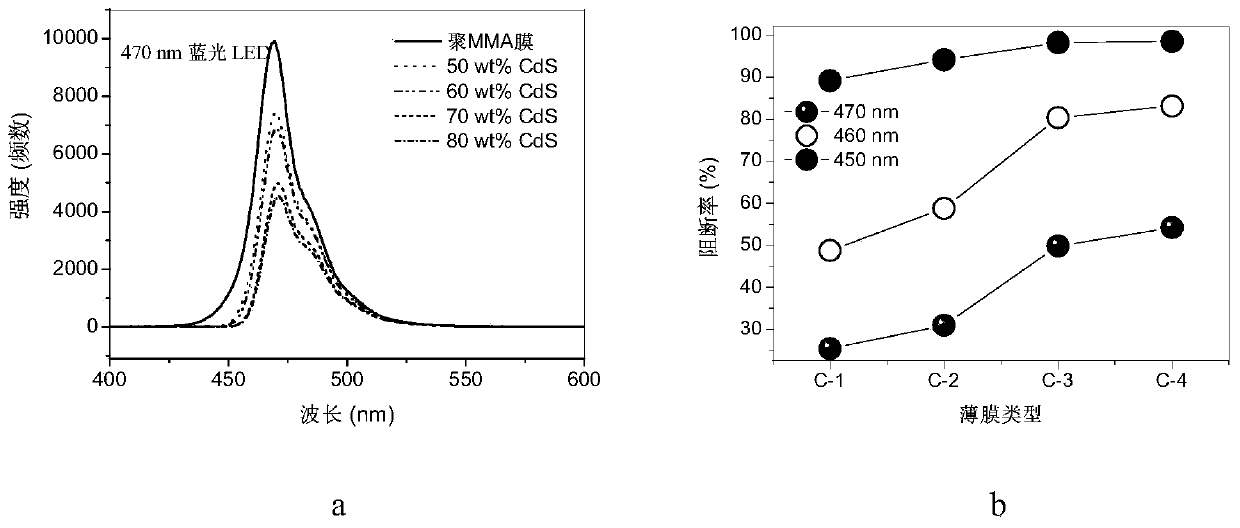

Preparation method of blue light blocking film with adjustable cut-off wavelength and narrow absorption transition band

ActiveCN110746556AImprove photoelectric propertiesSignificant size effectOptical filtersMethacrylateFunctional monomer

The invention provides a preparation method of a blue light blocking film with adjustable cut-off wavelength and narrow absorption transition band. The preparation method comprises the following steps: firstly, preparing CdS nanoparticles rich in hydroxyl on the surface; then, grafting a polymerizable functional monomer isocyanatoethyl methacrylate on the surfaces of the CdS nanoparticles to synthesize polymerizable CdS nanoparticles; and finally, copolymerizing the polymerizable CdS nanoparticles with a polymerization monomer to prepare the blue light blocking film containing the CdS nanoparticles. According to the invention, few types of raw materials are used, the preparation method is simple, steps are short, energy is saved, environment is protected, and cost is low. The CdS nanoparticles in the prepared blue light blocking film are in a highly dispersed state, and the blue light blocking film has the characteristics of high light transmission, blocking of harmful short-wave bluelight, transmission of beneficial long-wave blue light, adjustable cut-off wavelength, narrow absorption transition band and the like.

Owner:山东济清科技服务有限公司

A kind of epitaxial growth method that improves LED luminous efficiency

InactiveCN104332544BComposite Luminous Efficiency DecreaseWeaken energySemiconductor devicesQuantum wellLight emission

The invention provides a novel LED epitaxial growth method which can effectively improve the lighting efficiency of LED epitaxial structures. The method comprises the links of N-GaN layer growth, multi-quantum well layer growth and P-GaN layer growth, wherein the multi-quantum well layer is of a structure of a plurality of pairs of AlxGa <1-x> N / InyGa <1-y> N, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1; the multi-quantum well layer growth link includes three growth stages in sequence, wherein the AlxGa1-xN quantum barrier is subjected to p type doping in the first stage, the AlxGa1-xN quantum barrier is not doped in the second stage, and the AlxGa1-xN quantum barrier is subjected to n type doping in the third stage; a p type doped AlGaN stopping layer grows, and then the P-GaN layer growth link is performed.

Owner:西安利科光电科技有限公司

Thermal growth Cr203 film type M Cr nano composite plating and producing process and application

InactiveCN1291070CComposition controllableIncrease the amount of compoundingElectrolytic coatingsGrown filmThermal growth

The thermally grown Cr2O3 film type M-Cr nano composite coating consists of nano crystal M coating and nano metal Cr grains dispersed in the coating, where M is Ni, Fe or Co. Of the nano metal Cr grain, the lowest content is 7.3-13 wt%, and the highest content is the maximum compounded amount, 25 wt% at present, and M is the rest. The nano composite Ni-Cr, Fe-Cr or Co-Cr coating is prepared through composite electroplating process to deposit metal M and Cr coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Cr2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

A high corrosion-resistant alloy flange and its preparation method

ActiveCN112126869BImprove corrosion resistanceImprove heat resistanceFlanged jointsCorrosion preventionCorrosion resistant alloyZinc borate

Owner:无锡市星达石化配件有限公司

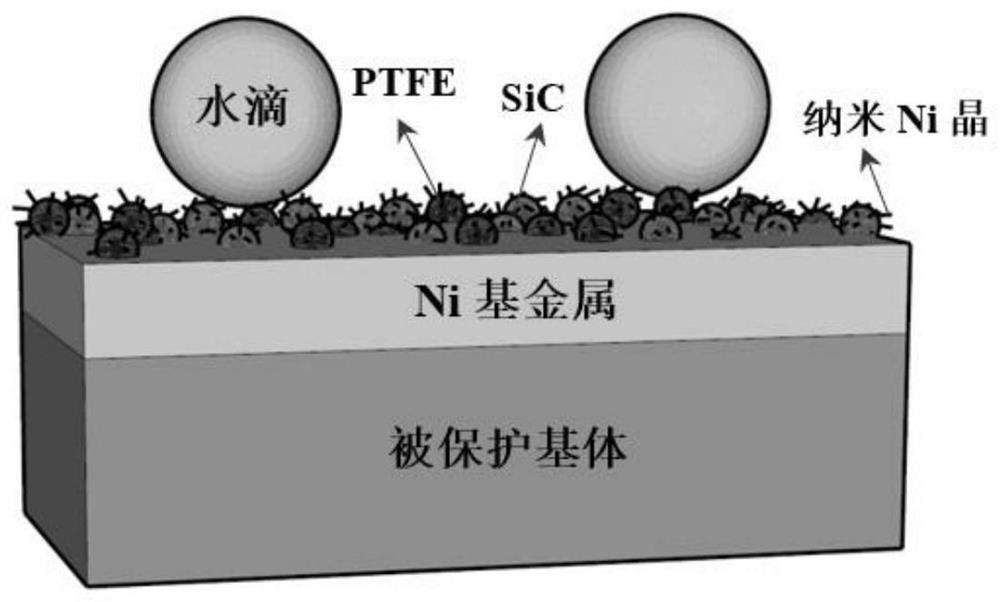

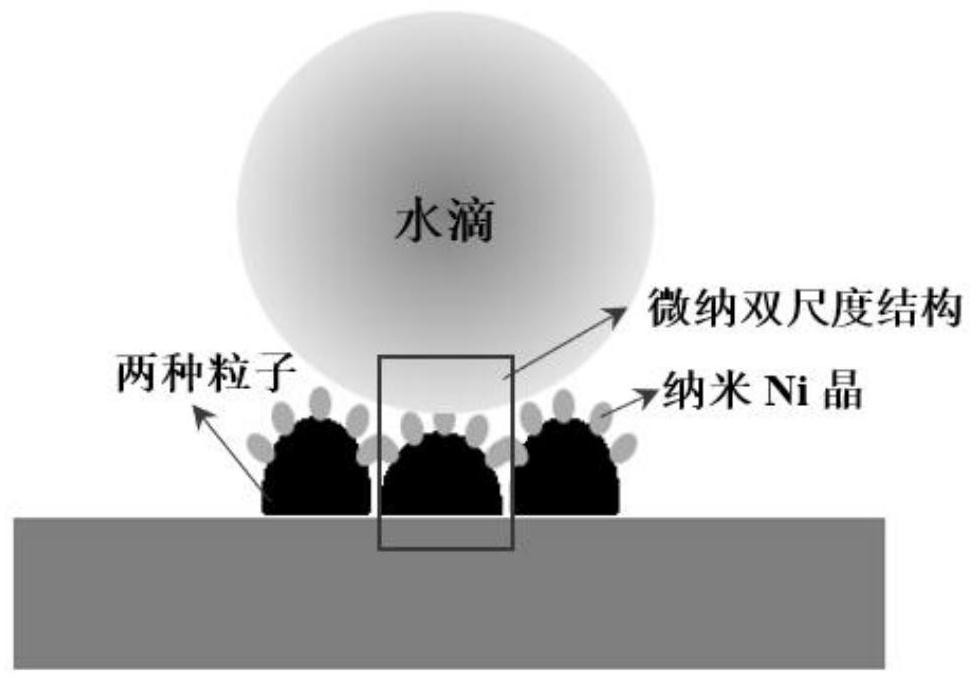

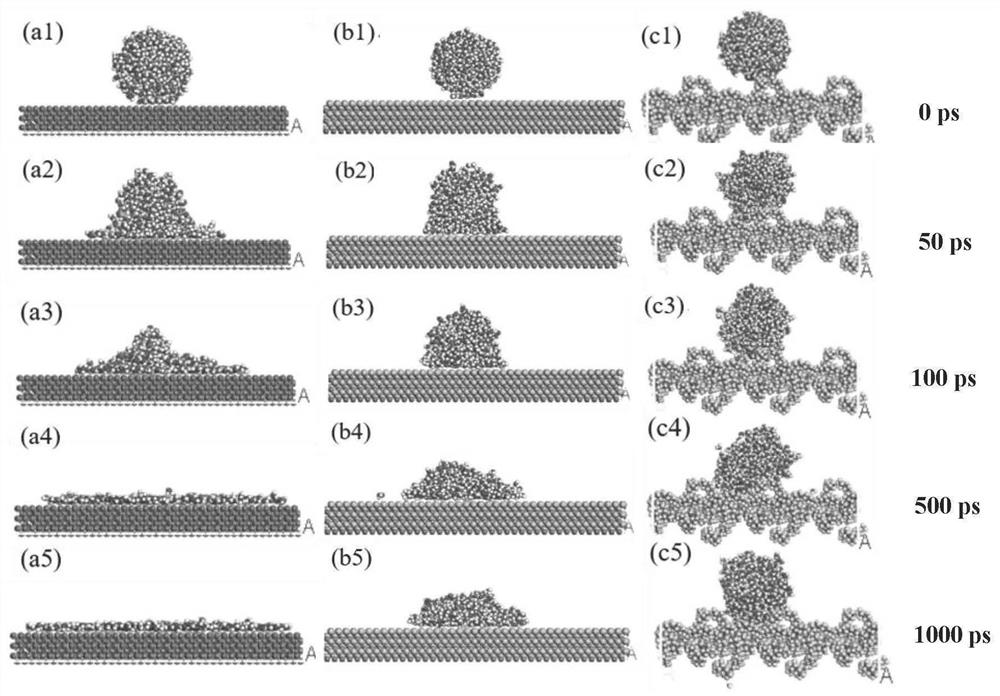

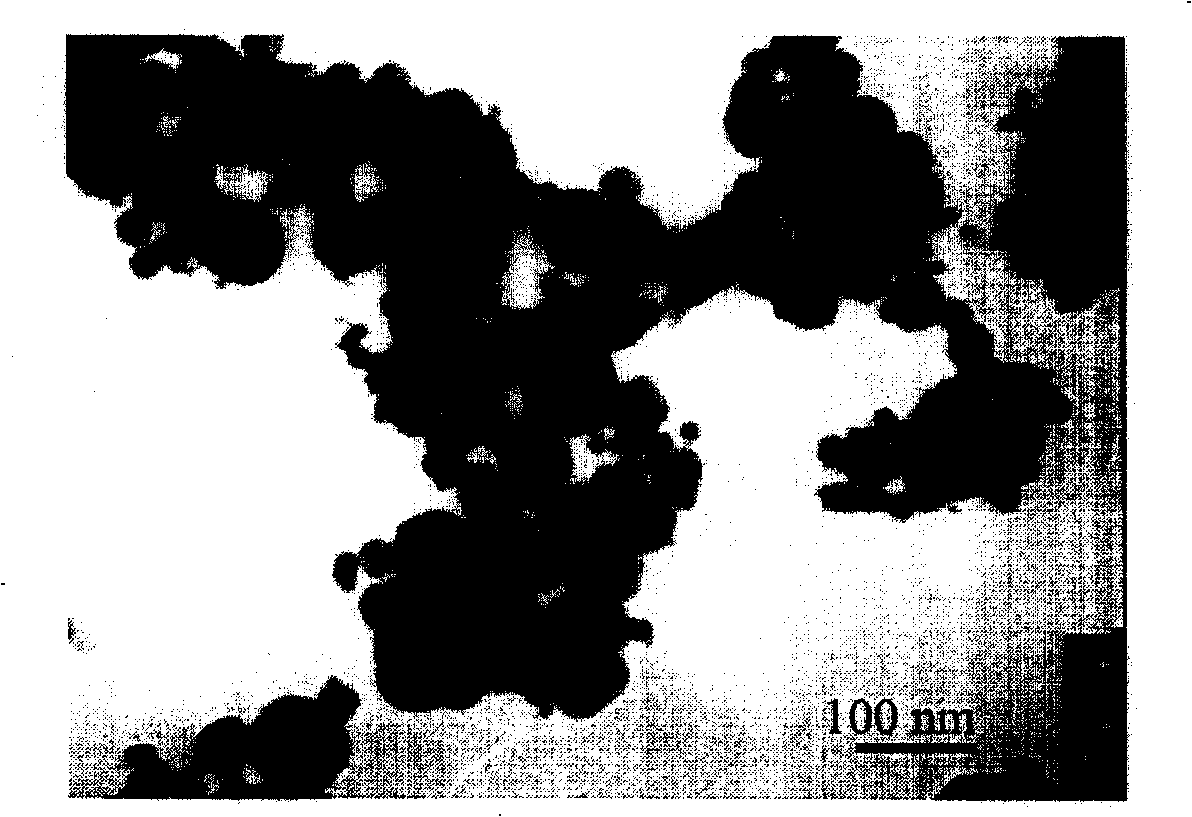

A kind of ni-ptfe-sic superhydrophobic anticorrosion coating and preparation method thereof

ActiveCN113445107BLow self-lubricationReduce hardnessElectrolytic coatingsNanoparticleHigh wear resistance

The invention relates to the technical field of super-hydrophobic coatings, and provides a Ni-PTFE-SiC super-hydrophobic anti-corrosion coating and a preparation method thereof. The invention adds PTFE and SiC nanoparticles into the nickel-based plating solution, utilizes the low surface energy and low friction coefficient of PTFE and the high hardness and high wear resistance of SiC, and prepares Ni-PTFE-SiC on the metal substrate by electrodeposition Super-hydrophobic anti-corrosion coating, no need to use low surface energy substances for secondary modification of the coating. The super-hydrophobic anti-corrosion coating has a micro-nano dual-scale structure, including a nickel metal layer and PTFE and SiC nanoparticles embedded in the nickel metal layer. Nickel crystals are adsorbed on the nanoparticles, and a large number of micro-pores can be formed between the micro-nano dual-scale structure. Trapping air makes the coating achieve good hydrophobicity. After testing, the Ni-PTFE-SiC super-hydrophobic anti-corrosion coating has a good anti-corrosion effect on the substrate, and has excellent mechanical stability and durability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thermal growing Cr2O3 film type Cu-Ni-Cr nano composite coating and preparation and use

InactiveCN100455704CIncrease the amount of compoundingComposition controllableElectrolytic coatingsNanoparticleGrown film

The present invention discloses a kind of thermal grown Cr2O3 type nanometer composite Cu-Ni-Cr coating and its preparation and application. The nanometer composite Cu-Ni-Cr coating is prepared with Cu-Ni alloy and nanometer Cr powder and have Cu-Ni alloy base with different Cu / Ni ratio, and Cr content of 15-30 wt%. The preparation process of the nanometer composite Cu-Ni-Cr coating is to electroplate Cu-Ni alloy and Cr onto Cu substrate through conventional electric co-deposition. The present invention has simple technological process, controllable coating components and low cost, and the prepared nanometer composite coating is compact and with homogeneously distributed nanometer Cr grains. The coating of the present invention may be used as high temperature oxidation resisting coating on Cu or Cu base alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com