Silicone rubber sponge-forming emulsion composition and method for producing silicone rubber sponge

An emulsion composition and a technology of a manufacturing method are applied in the field of silicone rubber sponge-forming emulsion compositions, which can solve the problems of inability to form cells, instability, and difficulty in obtaining low-hardness silicone rubber sponges, etc., and achieve mechanical strength improvement and mechanical strength. The effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 ~ Embodiment 7

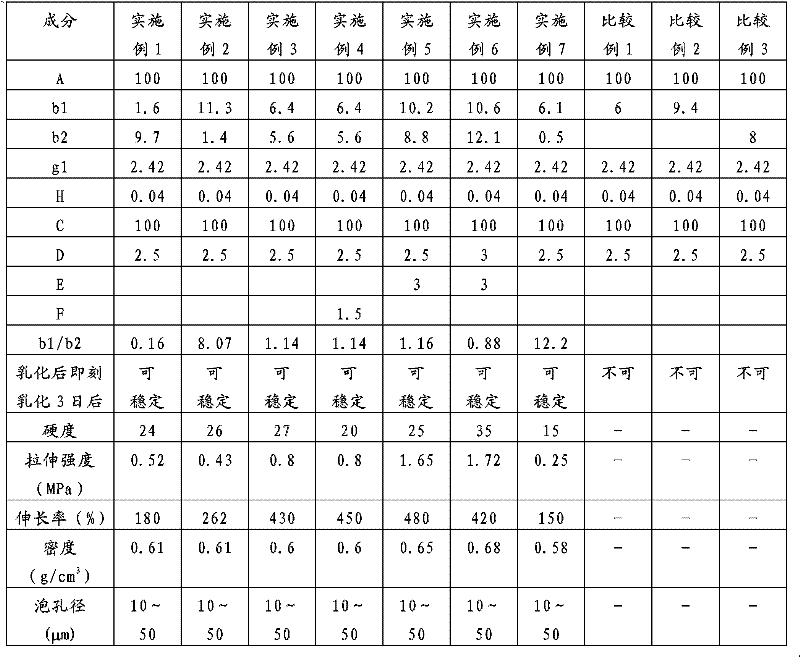

[0155] The mixing ratio of each component A, b1, b2, g1, H, C, D, E, and F in the silicone rubber sponge-forming emulsion composition produced by the above-mentioned emulsification method and emulsification conditions is shown in the table.

[0156] In addition, the blending ratio of the above-mentioned fumed silica (b1) / the above-mentioned precipitated silica (b2) was calculated from the blending ratio of AB-1 and AB-2.

[0157] Next, 0.015 parts of component g2 was mixed uniformly by hand in 100 parts of this silicone rubber sponge-forming emulsion composition, and after degassing with a vacuum pump, it was cast into a mold with a thickness of 2 mm, and it was cooled at 80° C. for 10 minutes. After curing, a silicone rubber-like molded sheet in a wet state is obtained. The molded sheet was placed in a hot-air circulation oven at 120° C. and dried for 3 hours to obtain a sheet-shaped open-cell silicone rubber sponge. The density, hardness, tensile strength, elongation and ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com