Oil or fat composition for lauric chocolates, and chocolate containing same

A technology of oil composition and chocolate, which is applied in the direction of edible oil/fat, fat oil/fat separation, application, etc., can solve the problems of less compounding amount, short shelf life, insufficient and other problems, and achieve anti-blooming, fast curing speed, The effect of flavor improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

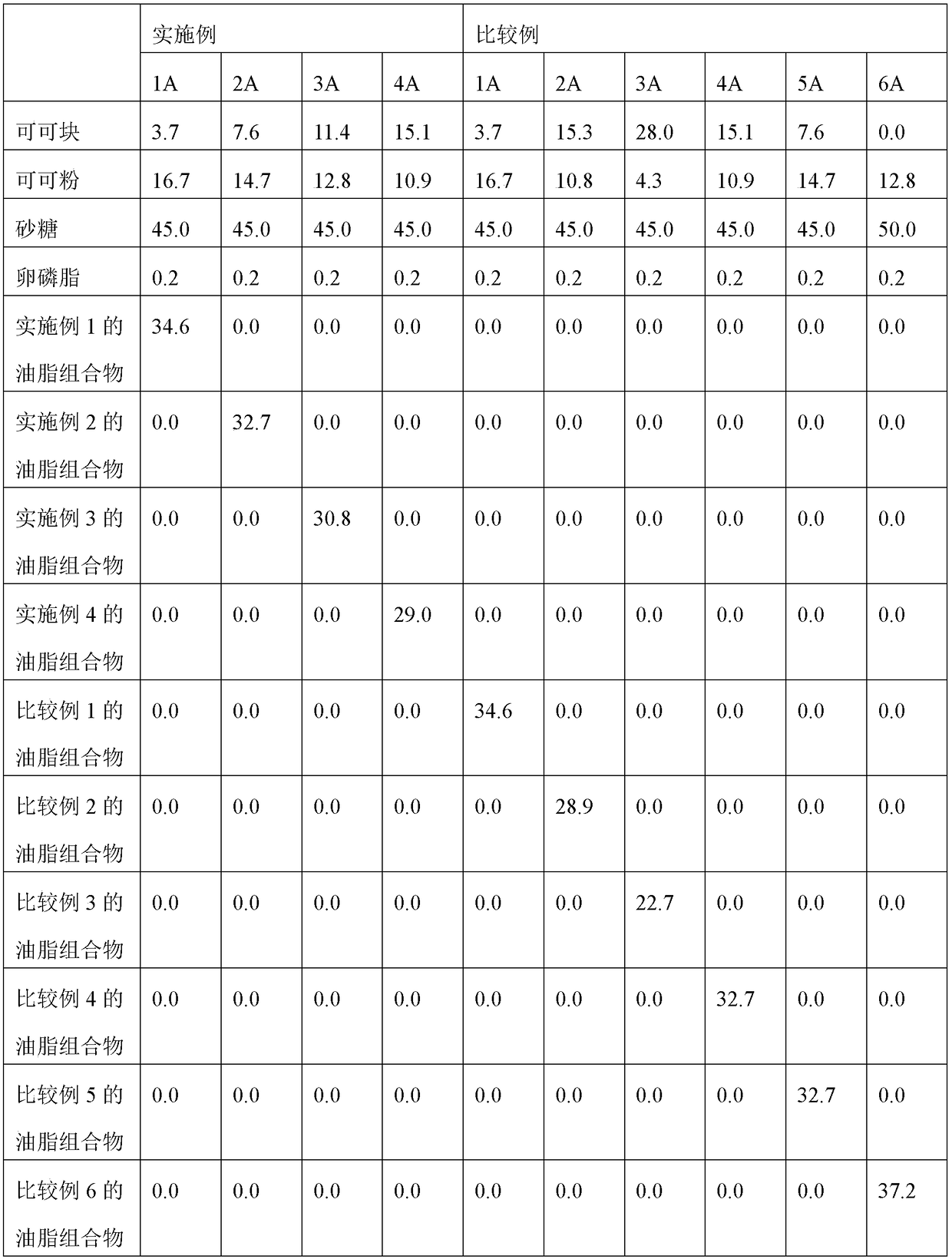

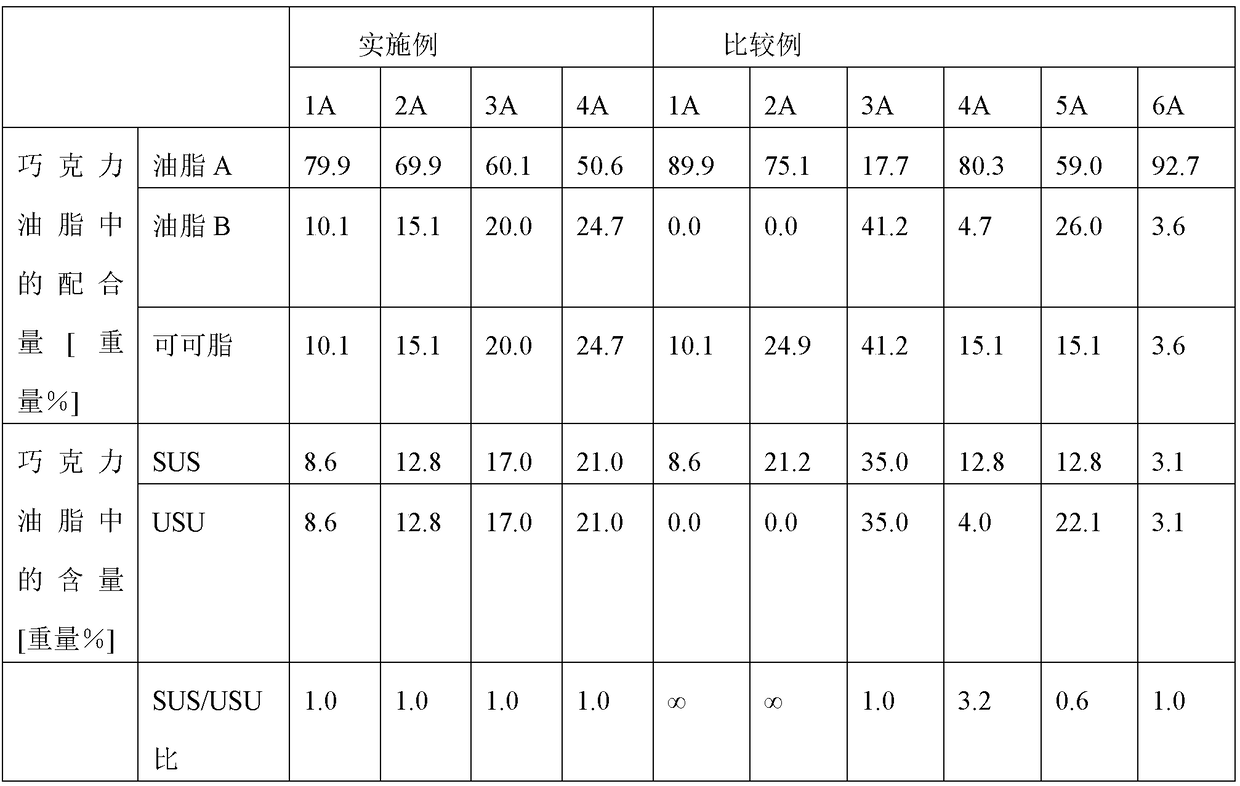

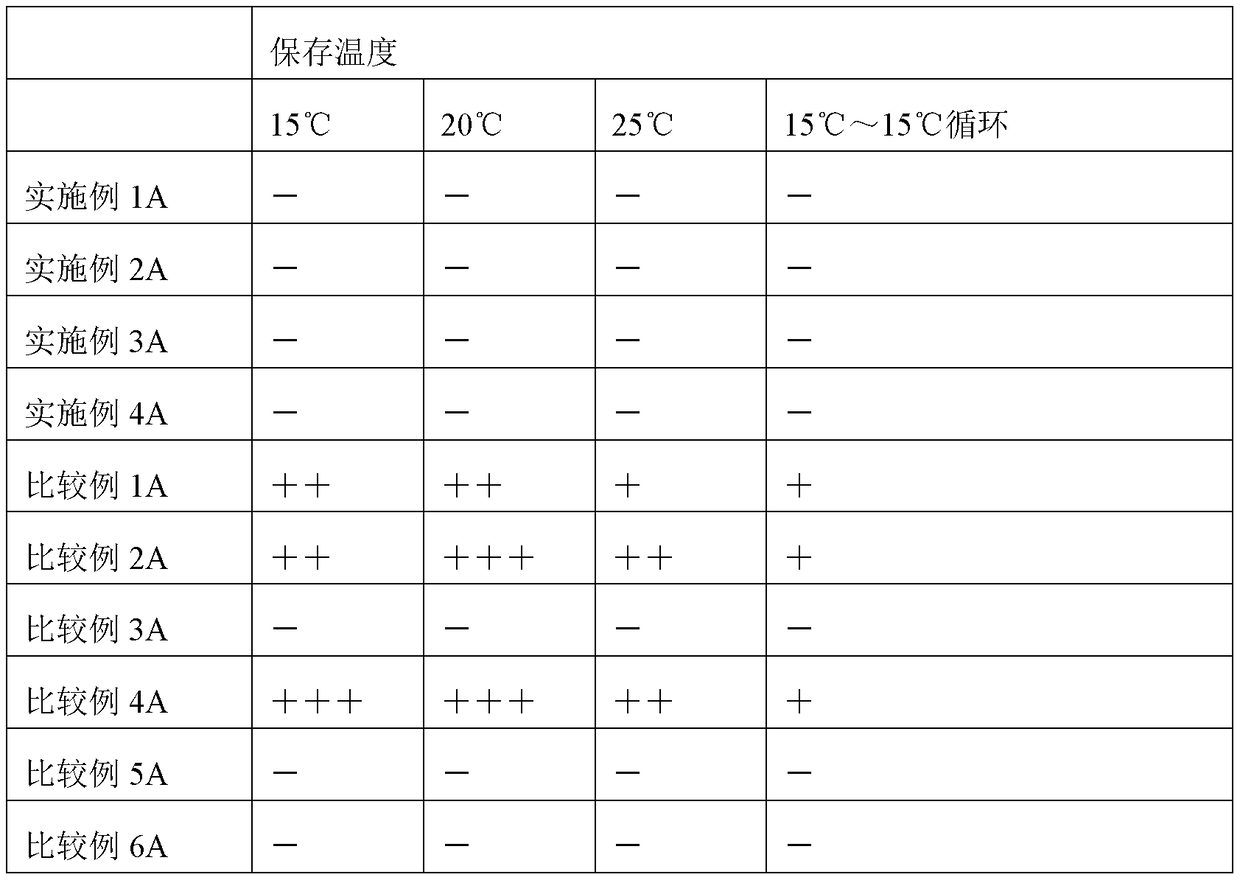

Examples

Embodiment

[0039] Although examples are described below, the technical idea of the present invention is not limited by these examples. It should be noted that, unless otherwise specified,% and parts are based on weight.

[0040] (Production of Lauric Acid Type Grease A)

[0041] Grease Aa: Palm kernels are extremely hardened oils with increased melting point (Saturated fatty acid content of less than 14 carbon atoms is 81%, SFC at 10°C is 97%, SFC at 20°C is 96%, SFC at 40°C Is 0%).

[0042] Fat Ab: Palm kernel partially hydrogenated fat and oil (Saturated fatty acid content of 14 carbon atoms is 69%, SFC at 10°C is 95%, SFC at 20°C is 84%, and SFC at 40°C is 1%).

[0043] Fat Ac: 85 parts of palm kernel oil, 5 parts of palm oil, and 10 parts of high erucic acid rapeseed extremely hardened oil. After transesterification, extremely hardened oil (the saturated fatty acid content of 14 carbon atoms is 59%, 10°C When the SFC is 96%, the SFC at 20°C is 86%, and the SFC at 40°C is 5%).

[0044] Fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com