Deposition process for improving compound quantity of nanoparticles in electric deposition

A nanoparticle and deposition process technology, applied in the field of electrodeposition process, can solve the problems affecting the performance of the composite deposition layer, the short residence time of the cathode surface, and the small composite amount of nanoparticles, and achieves fine grain size, prolonged residence time, and electric field distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

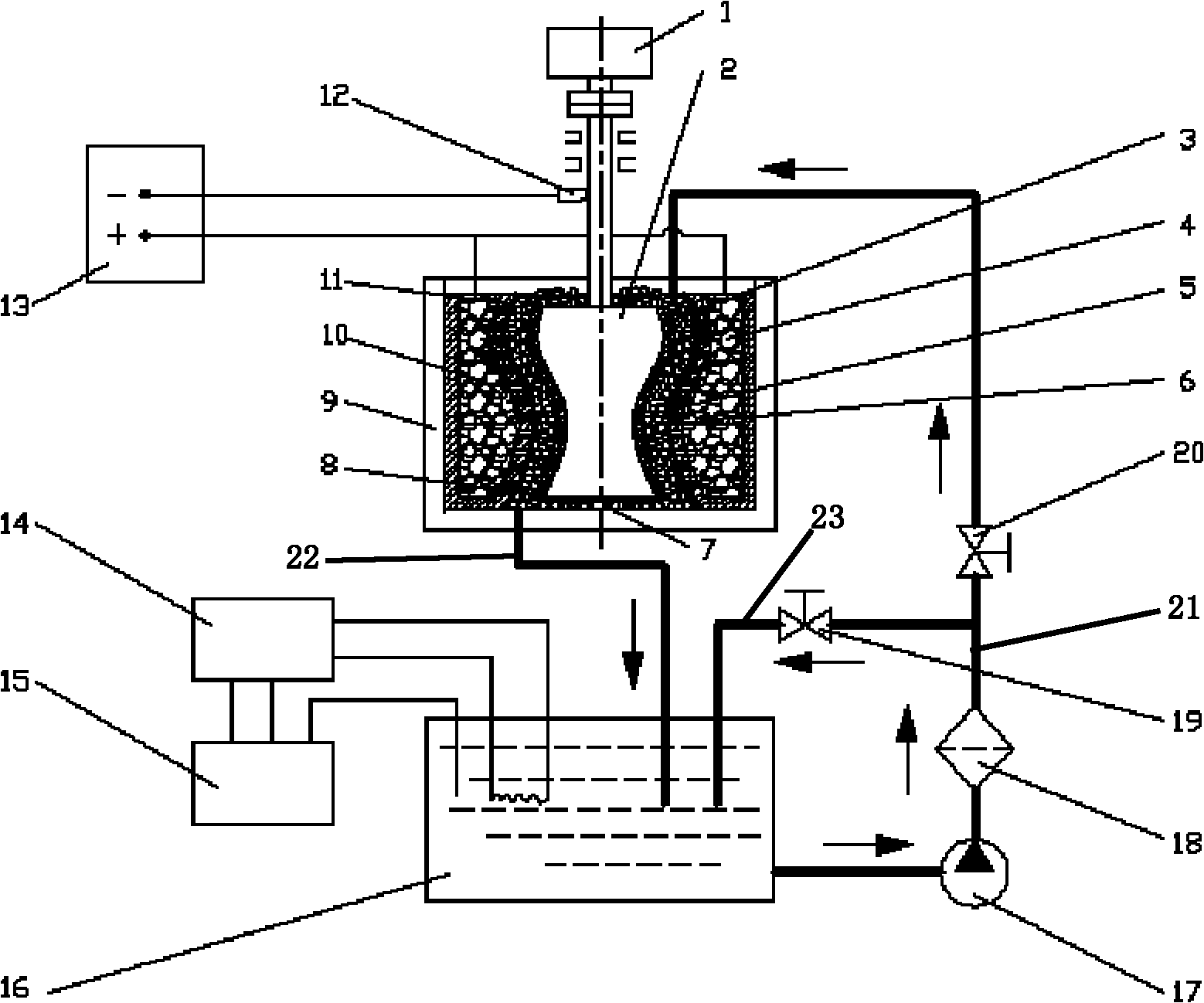

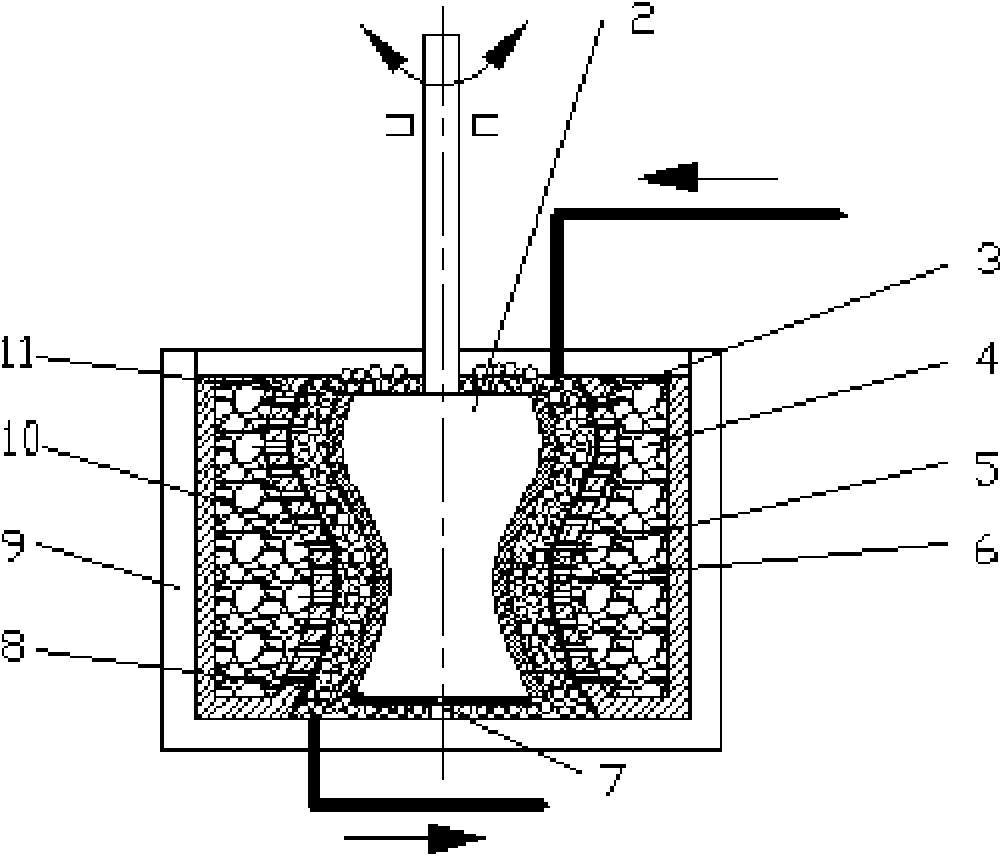

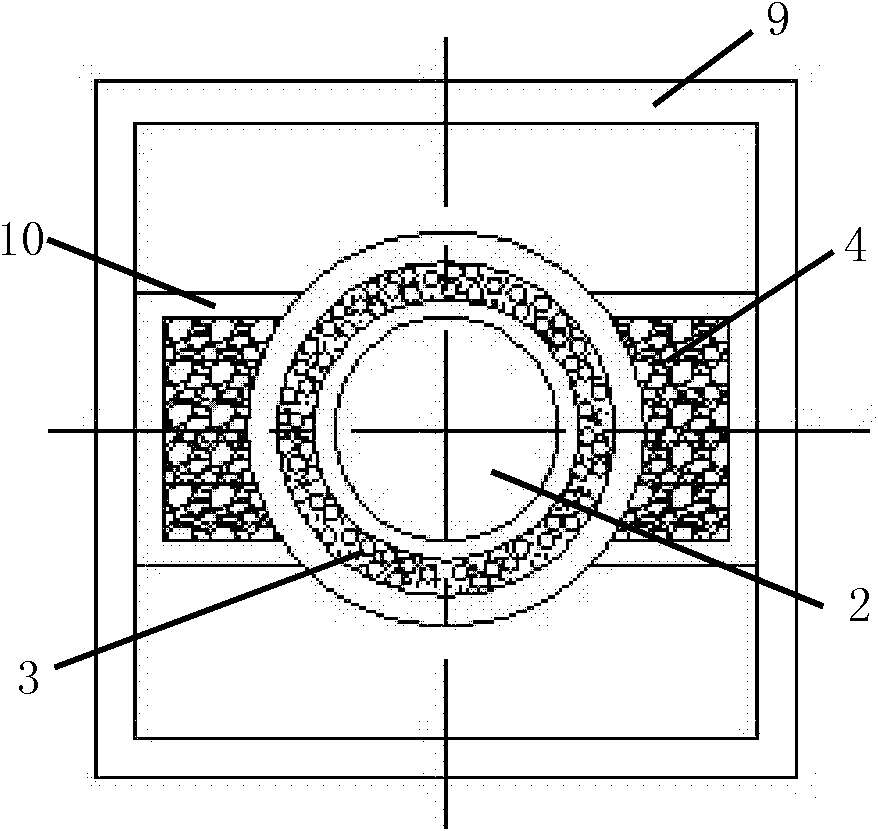

[0022] Embodiment: a kind of deposition process that improves the composite amount of nanoparticles in electrodeposition,

[0023] The mandrel 2 as the cathode and the first phase metal pole 4 as the anode are respectively placed in the electroplating solution, an annular anode basket 10 is arranged between the mandrel 2 and the first phase metal pole 4, and the annular anode basket 10 A number of through holes are opened on the side facing the mandrel 2, and the first phase metal pole 4 is composed of several first phase metal cakes, and the several first phase metal cakes are placed in the annular anode basket 10, and the annular anode basket 10 and a number of non-conductive hard particles 3 are placed between the mandrel 2, and the diameters of the first-phase metal cake and the non-conductive hard particles 3 are larger than the diameter of the through hole; the through hole is used to form the electrodeposition required The electric field and the passage of metal ions. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com