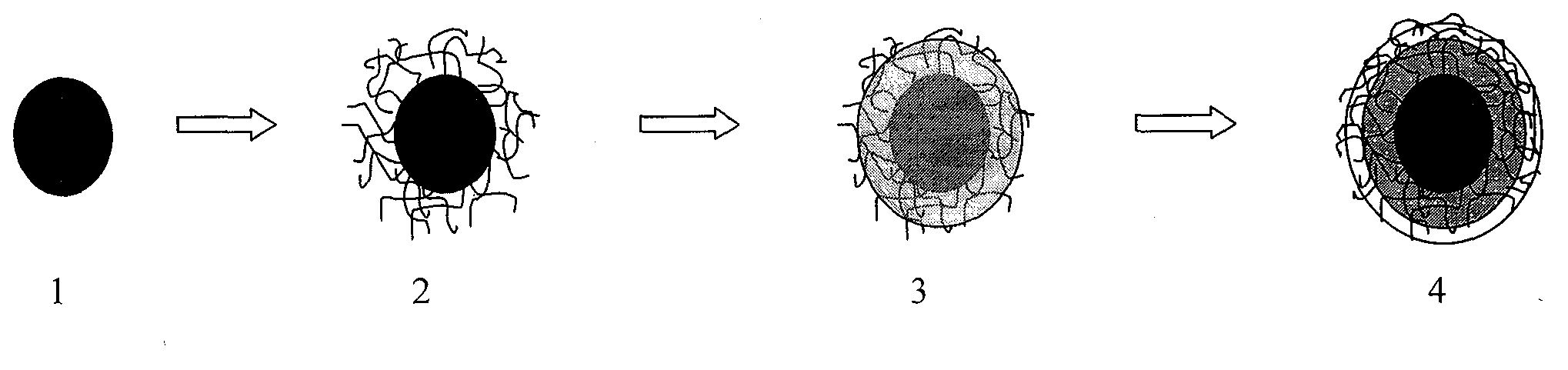

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

A composite material and core-shell structure technology, applied in the field of electrochemistry, can solve the problems of polysulfur materials such as unstable structure, poor cycle stability, and low sulfur utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

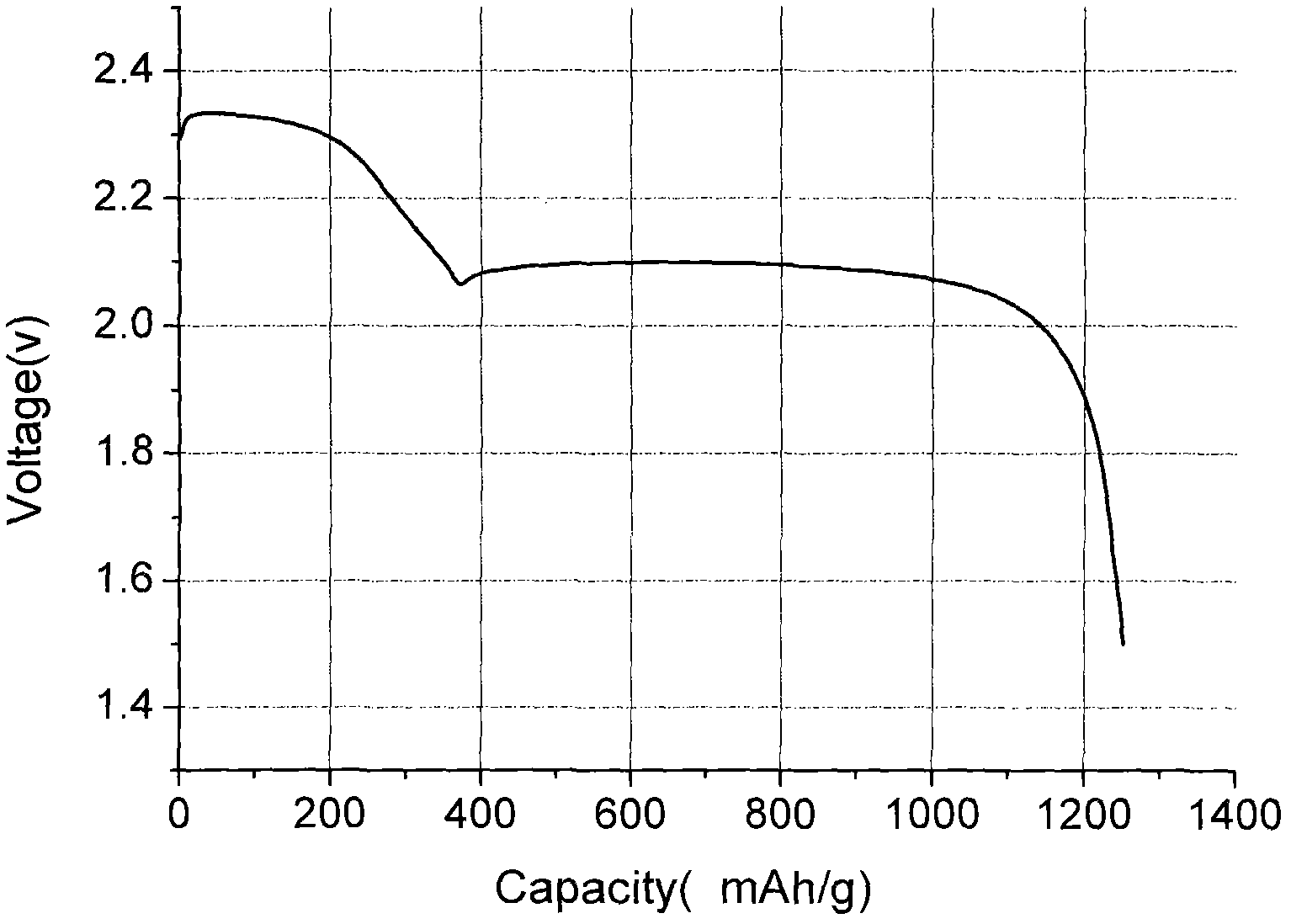

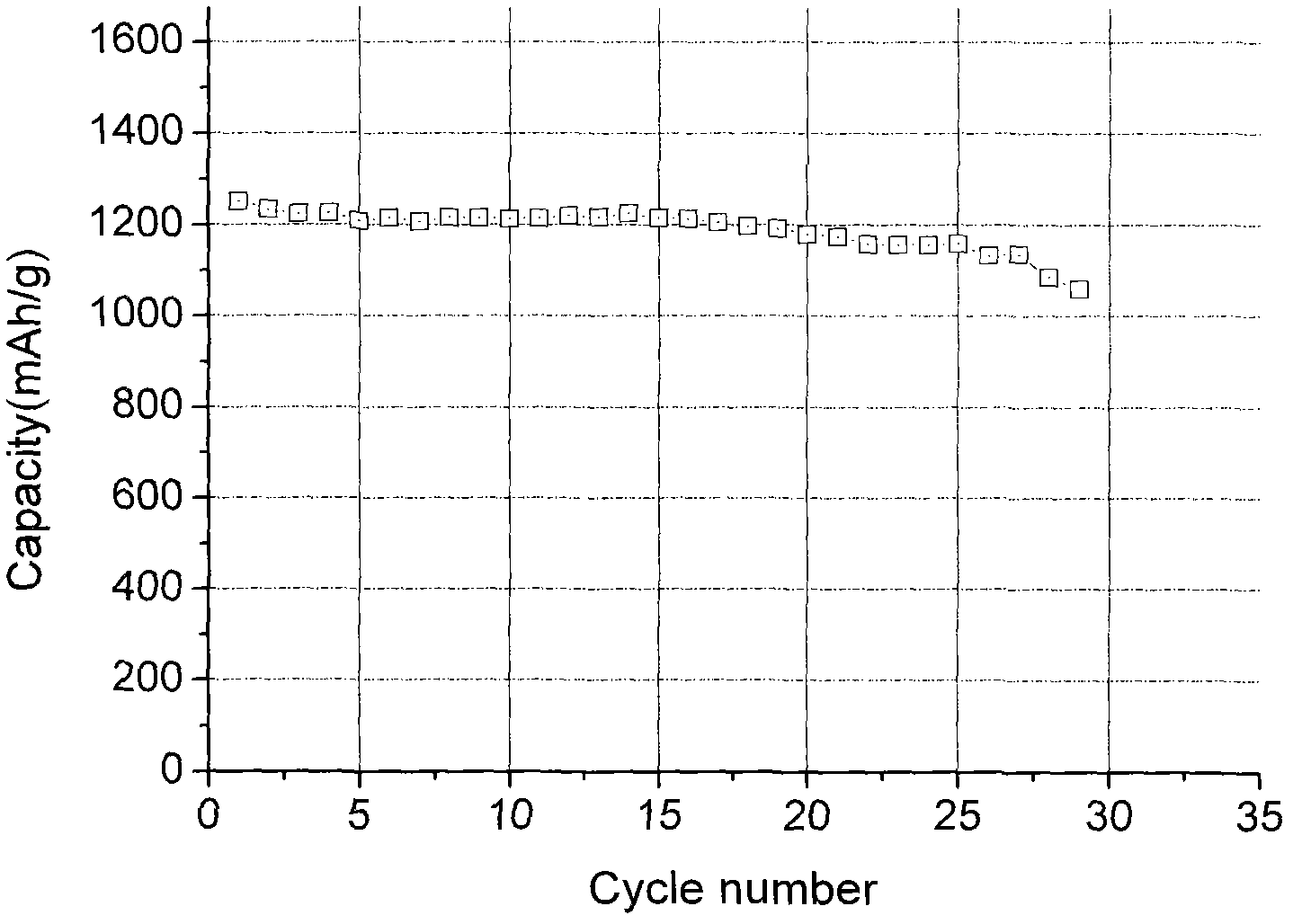

Examples

Embodiment 1

[0087] Put 15g of carbon black in a three-necked flask and add 500mL of concentrated HNO3 solution dropwise during stirring, ultrasonicate for 30min, heat in a water bath to 80°C, condense and reflux for 4h, stop the reaction, filter, wash, and obtain groups containing hydroxyl, carboxyl, ester, etc. functionalized carbon.

Embodiment 2

[0089] Prepare 500mL of 0.25mol / L K2C r2O7, 1mol / L hydrochloric acid mixed solution, transfer it into a 1000mL three-neck flask, add 15g of carbon black, ultrasonically disperse for 30min, stir mechanically at 80°C for 4h, cool, and rinse repeatedly with a large amount of deionized water until the filtrate until neutral. The product was dried in a vacuum oven at 80° C. for 24 hours and then ground to obtain functionalized carbons containing hydroxyl groups, carboxyl groups, ester groups and other groups.

Embodiment 3

[0091] Add 15g of carbon black into the reaction flask, add dropwise a mixed solution of 5ml of concentrated sulfuric acid and 100ml of acetic anhydride with stirring, keep warm at 70°C, and complete the dropwise addition in 1 hour. After cooling to room temperature, carefully pour into 500ml of water while stirring, filter and wash , to obtain a functionalized carbon containing a sulfonic acid group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com