Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

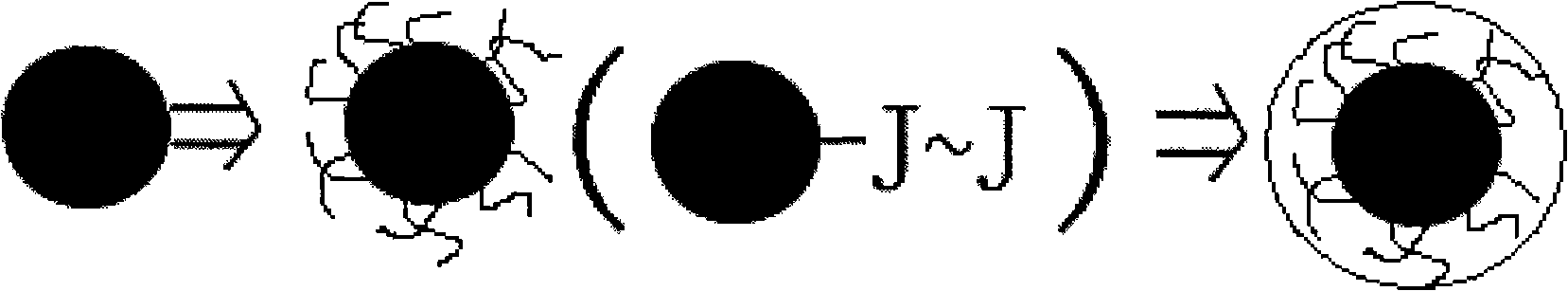

A network structure and composite material technology, which is applied in the fields of nano-carbon materials, nano-carbon-sulfur composite materials and their preparation, can solve the problems of low utilization rate of sulfur, poor cycle stability, unstable structure of polysulfide materials, etc. Dissolution-diffusion loss, outstanding electrical conductivity, the effect of improving electron or ion transport rate and reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Put 15g of carbon black in a three-necked flask and add concentrated HNO dropwise during stirring 3 The solution was 500mL, ultrasonicated for 30min, heated to 80°C in a water bath, condensed and refluxed for 4h, the reaction was stopped, filtered, and washed to obtain functionalized carbon containing hydroxyl, carboxyl, ester and other groups.

Embodiment 2

[0104] Prepare 0.25mol / L K 2 C r 2 o 7 , Transfer 500mL of 1mol / L hydrochloric acid mixed solution into a 1000mL three-necked flask, add 15g of carbon black, ultrasonically disperse for 30min, stir mechanically at a high speed at 80°C for 4h, cool, and rinse repeatedly with a large amount of deionized water until the filtrate is neutral. The product was dried in a vacuum oven at 80° C. for 24 hours and then ground to obtain functionalized carbons containing hydroxyl groups, carboxyl groups, ester groups and other groups.

Embodiment 3

[0106] Add 15g of carbon black into the reaction flask, add dropwise a mixed solution of 5ml of concentrated sulfuric acid and 100ml of acetic anhydride with stirring, keep warm at 70°C, and complete the dropwise addition for 1 hour. After cooling to room temperature, carefully pour it into 500ml of water while stirring, filter, and wash. A functionalized carbon containing sulfonic acid groups is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com