Sulfur-doped three-dimensional porous graphene/sulfur composite positive electrode material and preparation method and application thereof

A composite cathode material and three-dimensional porous technology, which is applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve problems such as poor cycle performance, low energy density, and long preparation process, and achieve high porosity High efficiency, large specific surface area, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

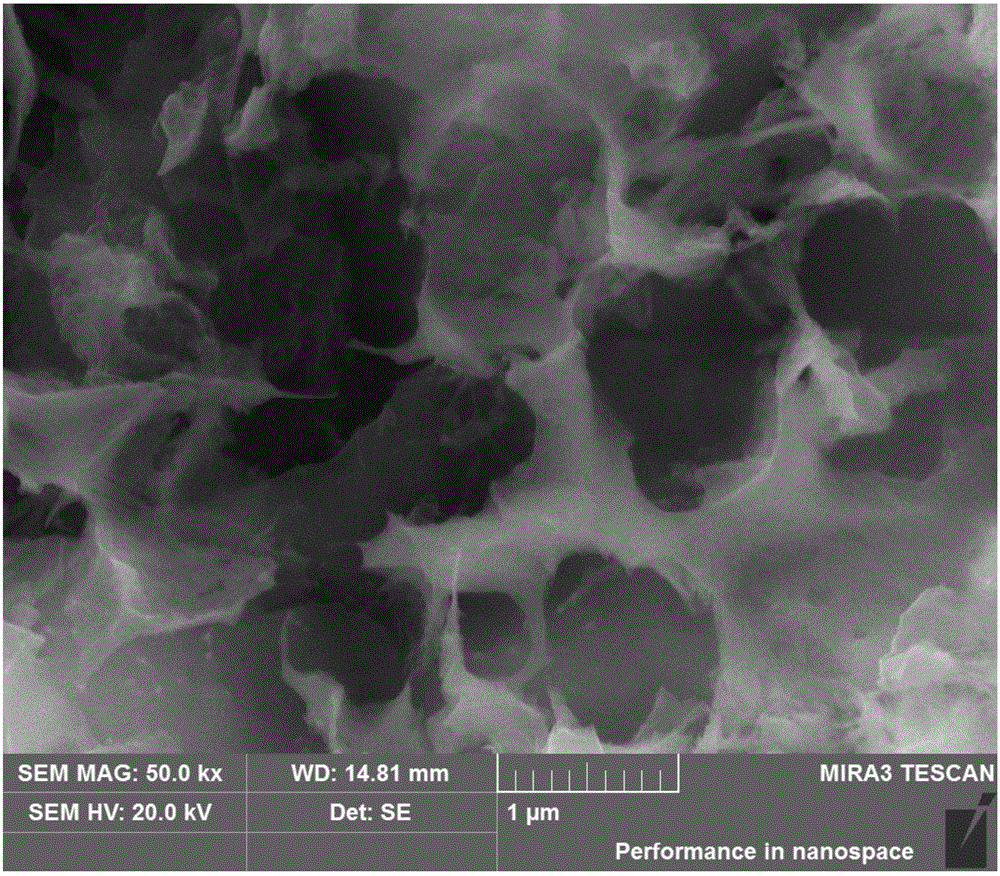

[0037] After ultrasonicating 400mL of graphene oxide dispersion with a concentration of 2mg / L for 2 hours, add 1.6g of sodium bisulfite with stirring, raise the temperature to 50°C and keep it for 2 hours, take out a small amount of the reacted solution, wash it several times, pass through X X-ray photoelectron spectroscopy was used to characterize, and the results showed that the doping amount of sulfur accounted for 0.2%. Then add 4 g of sodium sulfide into the above reacted solution, and stir for 0.5 hour. The above solution was suction-filtered and washed 3 times with deionized water, and the filter cake was transferred to a freeze dryer to dry for 24 hours to obtain a sulfur-doped three-dimensional porous graphene / sulfur composite material. The actual sulfur content was obtained by thermogravimetric testing. 35 wt.%. Gained composite positive electrode material, conductive carbon black, polyvinylidene fluoride (PVDF) are uniformly mixed according to a mass ratio of 8:1:1...

Embodiment 2

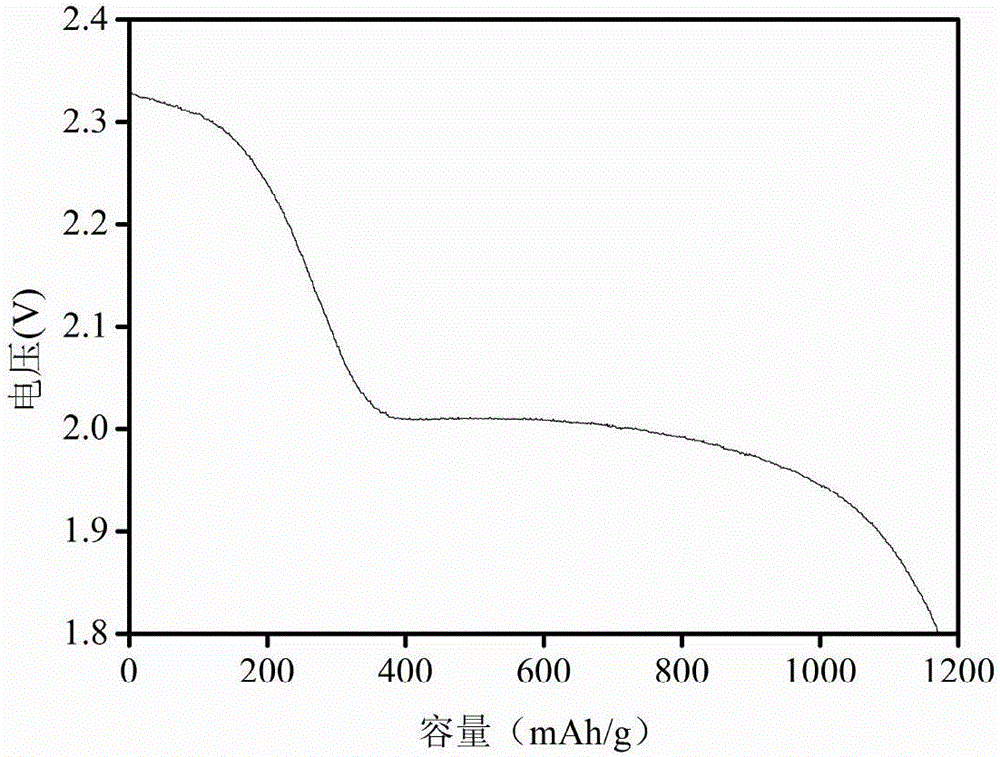

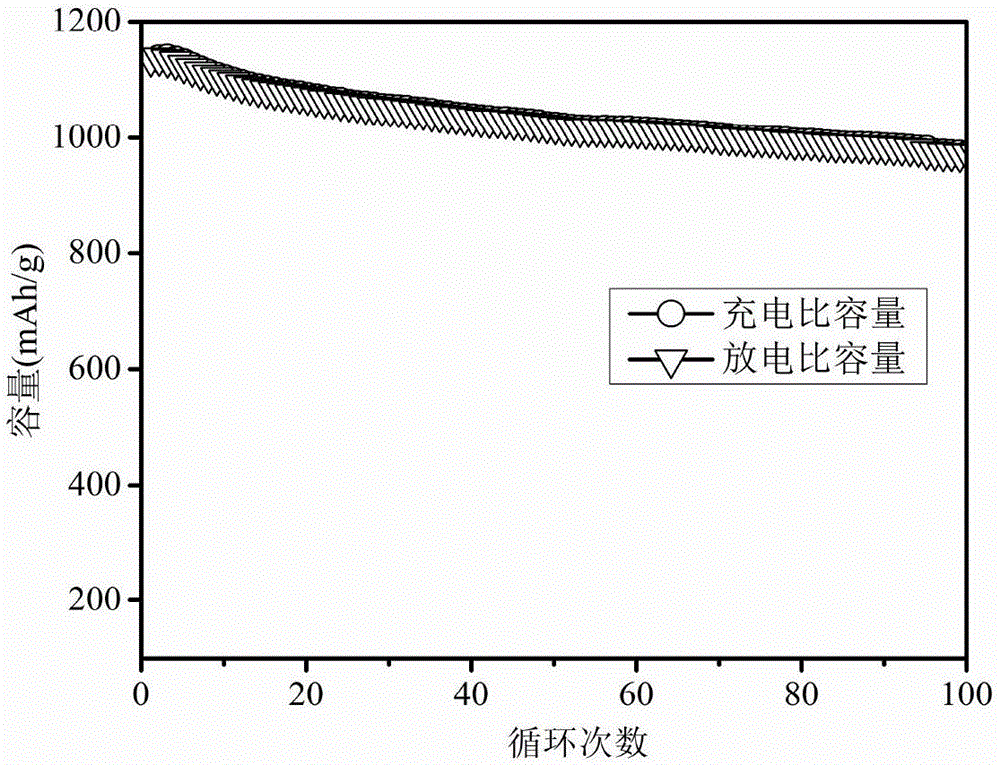

[0040] After ultrasonicating 400mL of graphene oxide dispersion with a concentration of 5mg / L for 2 hours, stir and add 4g of sodium bisulfite, raise the temperature to 50°C and keep it for 2 hours, take out a small amount of the reacted solution, wash it several times, and pass X-ray Characterized by photoelectron spectroscopy, the results show that the doping amount of sulfur atoms accounts for 3%. Then add 7 g of sodium sulfide into the above reacted solution, and stir for 0.5 hour. The above solution was suction-filtered and washed 3 times with deionized water, and the filter cake was transferred to a freeze dryer to dry for 24 hours to obtain a sulfur-doped three-dimensional porous graphene / sulfur composite material. The actual sulfur content was obtained by thermogravimetric testing. 52.1 wt.%. Gained composite positive electrode material, conductive carbon black, polyvinylidene fluoride (PVDF) are uniformly mixed according to a mass ratio of 8:1:1, and dispersed in a c...

Embodiment 3

[0043] After ultrasonicating 400mL of graphene oxide dispersion with a concentration of 2mg / L for 2 hours, stir and add 6g of sodium bisulfite, raise the temperature to 50°C and keep it for 2 hours, take out a small amount of the reacted solution, wash it several times, and pass X-ray Characterized by photoelectron spectroscopy, the results show that the doping amount of sulfur accounts for 5% of atoms. Then add 8 g of sodium sulfide into the above reacted solution, and stir for 0.5 hour. The above solution was suction-filtered and washed 3 times with deionized water, and the filter cake was transferred to a freeze dryer to dry for 24 hours to obtain a sulfur-doped three-dimensional porous graphene / sulfur composite material. The actual sulfur content was obtained by thermogravimetric testing. 73.2 wt.%. Gained composite positive electrode material, conductive carbon black, polyvinylidene fluoride (PVDF) are uniformly mixed according to a mass ratio of 8:1:1, and dispersed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com