A sulfur/porous carbon-coated carbon nanotube composite positive electrode material for lithium-sulfur batteries and its preparation method

A composite positive electrode material and nanotube composite technology, which is applied in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc., can solve problems such as low energy density, low sulfur loading, and small specific capacity of sulfur electrodes , to achieve the effect of large sulfur load, high utilization rate and inhibition of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

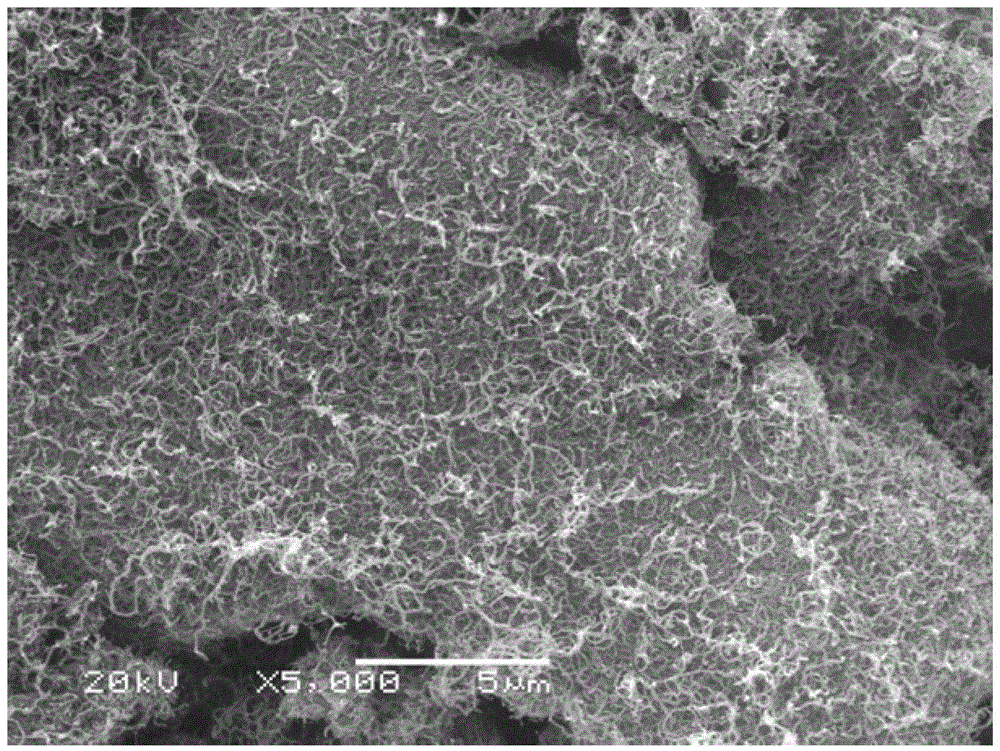

[0025] Add 1.0 g of single-walled carbon nanotubes (20 nm in diameter and 1 μm in length) to 200 mL of dopamine aqueous solution with a concentration of 5 mg / mL, and ultrasonicate for 2 h at room temperature to obtain a uniformly dispersed carbon nanotube suspension, and then continue to Under magnetic stirring, NaOH solution with pH=9 was slowly dropped into the suspension, and after mechanically stirring for 10 hours at room temperature, the product was washed three times with deionized water and ethanol to remove impurities and dopamine monolayers on the surface of the product. body, and polydopamine-coated carbon nanotube composites were obtained. A certain amount of polydopamine-coated carbon nanotube composite material was transferred to a tube furnace, and under the protection of inert gas nitrogen, the temperature was raised from room temperature to 800 °C at a heating rate of 10 °C / min, and kept for 10 h. After carbonization, a porous carbon-coated carbon nanotube com...

Embodiment 2

[0029] Add 0.8 g of multi-walled carbon nanotubes (100 nm in diameter and 5 μm in length) to 200 mL of dopamine aqueous solution with a concentration of 0.5 mg / mL, and ultrasonicate for 1 h at room temperature to obtain a uniformly dispersed carbon nanotube suspension, and then Under continuous magnetic stirring, slowly drop NaOH solution with pH=8 into the suspension, and after mechanically stirring for 8 hours at room temperature, wash the product three times with deionized water and ethanol to remove impurities and dopamine on the surface of the product. Monomer to obtain polydopamine-coated carbon nanotube composite material. A certain amount of polydopamine-coated carbon nanotube composite material was transferred to a tube furnace, and under the protection of inert gas nitrogen, the temperature was raised from room temperature to 1000 ° C at a heating rate of 5 ° C / min, and kept for 5 h. After carbonization, a porous carbon-coated carbon nanotube composite carbon mater...

Embodiment 3

[0031] Add 1.5g of single-walled carbon nanotubes (10nm in diameter and 500nm in length) into 100mL of dopamine aqueous solution with a concentration of 10mg / mL, and ultrasonicate for 3 hours at room temperature to obtain a uniformly dispersed carbon nanotube suspension, and then continue to Under magnetic stirring, the KOH solution with pH=8 was slowly dropped into the suspension, and after mechanically stirring for 5 hours at room temperature, the product was washed three times with deionized water and ethanol to remove impurities and dopamine monolayers on the surface of the product. body, and polydopamine-coated carbon nanotube composites were obtained. A certain amount of polydopamine-coated carbon nanotube composite material was transferred to a tube furnace, and under the protection of inert gas nitrogen, the temperature was raised from room temperature to 1200 °C at a heating rate of 15 °C / min, and kept for 8 hours. After carbonization, a porous carbon-coated carbon na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com