Symmetrical super capacitor

A supercapacitor, symmetrical technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of system power, rate and cycle performance deterioration, contact resistance increase, production cost increase, etc., to improve electronic and The effect of ion transport performance, reducing interface contact resistance, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

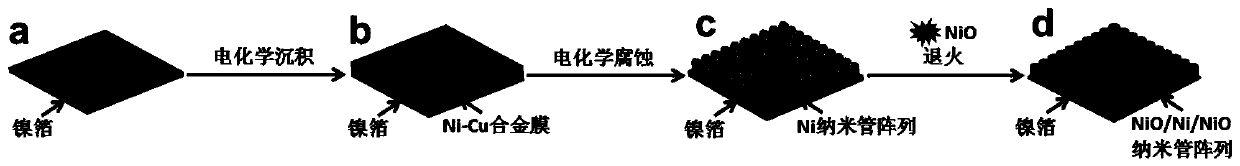

[0039] Specifically, see figure 1 , the preparation method of the nickel nanotube array with multilayer structure according to one embodiment of the present invention, comprises the following steps:

[0040] Step 1. Electrochemical deposition of Ni on nickel foil (a) x Cu 100-x Alloy film (b), wherein x=30~80;

[0041] Step 2, to the Ni x Cu 100-x The alloy film is dealloyed to obtain a nickel film with an oxide film on the surface;

[0042] Step 3, soaking the nickel film in an acidic aqueous solution to remove the oxide film on the surface of the nickel film;

[0043] Step 4, heating the nickel film treated in step 3 at 30-80° C. for 5-10 hours to obtain a nickel nanotube array (c) with a single-layer structure;

[0044] Step 5, annealing the nickel nanotube array at 100-600° C. for 5-20 minutes to obtain the nickel nanotube array (d) having a multilayer structure (nickel oxide layer, nickel layer and nickel oxide layer).

[0045] Specifically, the electrochemical dep...

Embodiment 1

[0068] One, prepare the nickel nanotube array with multilayer structure according to the following method:

[0069] (1) Electrochemical deposition of nickel-copper alloy film on a clean nickel foil (2cm×2cm, 15μm thick), electrochemical deposition conditions: current density is -4.5mA cm -2 , the time is 10min, the solution contains 1M NiSO 4 , 0.05M CuSO 4 and 0.5M H 3 BO 3 (pH value is adjusted to be 4), the ratio of Ni:Cu:B is 20:1:10, uses two electrode system, and wherein nickel foil and platinum sheet are respectively working electrode and counter electrode;

[0070] (2) The alloy film obtained by electrochemical deposition was in the same solution at 0.5V (relative to Li + / Li) under dealloying, the time is 5min;

[0071] (3) Soak the nickel film after the dealloying that step (2) obtains in 1M hydrochloric acid solution for 15min, remove the surface oxide film, then clean it up with deionized water;

[0072] (4) heating the nickel film obtained in step (3) at 60°...

Embodiment 2

[0089] Nickel oxide-nickel-nickel oxide nanotube arrays were prepared as follows:

[0090] (1) Electrochemical deposition of nickel-copper alloy film on a clean nickel foil (2cm×2cm, 15μm thick), electrochemical deposition conditions: current density is -1mA cm -2 , the time is 30min, the solution contains 5M NiSO 4 , 0.25M CuSO 4 and 2.5M H 3 BO 3 (pH value is adjusted to be 2), the ratio of Ni:Cu:B is 20:1:10, uses two electrode systems, and wherein nickel foil and platinum sheet are respectively working electrode and counter electrode;

[0091] (2) Dealloying the alloy film obtained by electrochemical deposition in the same solution at 1V (relative to Li+ / Li) for 3min;

[0092] (3) soak the nickel film after the dealloying that step (2) obtains in 0.5M hydrochloric acid solution for 20min, remove surface oxide film, then clean up with deionized water;

[0093] (4) heating the nickel film obtained in step (3) at 30° C. for 10 h in a vacuum oven to obtain a nickel nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com