Binder and rechargeable battery including same

A technology for rechargeable batteries and binders, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of active material shedding, pole piece breakage, etc., and achieve high adhesion, low crystallinity, and good ion transport performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0066] Examples 1-4 are respectively a kind of binder, which are all formed by copolymerization of isobutyl vinyl ether, 2,2,2 trifluoroethyl methacrylate, acrylamide and hydroxyethyl acrylate. Specifically, the composition of the binder in Example 1 is listed in Table 1.

[0067] Table 1

[0068]

[0069]Wherein, the binders in Examples 1-4 are all prepared by emulsion polymerization. Specifically, the process steps of the preparation method are: add deionized water and emulsifier in a three-necked flask, and then feed nitrogen to remove oxygen. Add a certain amount of monomers in Table 1, then add an initiator, raise the temperature, control the temperature, and start the polymerization reaction. After a period of reaction, add the remaining monomers and initiators. After the polymerization is completed, the obtained solid content is 20%~ The 30% stable emulsion has a number average molecular weight of 300,000 to 1,000,000.

Embodiment 5-8

[0138] Embodiments 5-8 are respectively a kind of binder, and its difference from Example 1 is that the monomer composition of the binder in Examples 5-8 is different from that of Example 1, and the specific components are listed in Table 8 .

[0139] Table 8

[0140]

[0141] Wherein, the vinyl ether monomer, fluorine-containing acrylate monomer, acrylamide monomer and acrylate monomer used in Examples 5-8 are the same as those in Example 1.

Embodiment 9-13

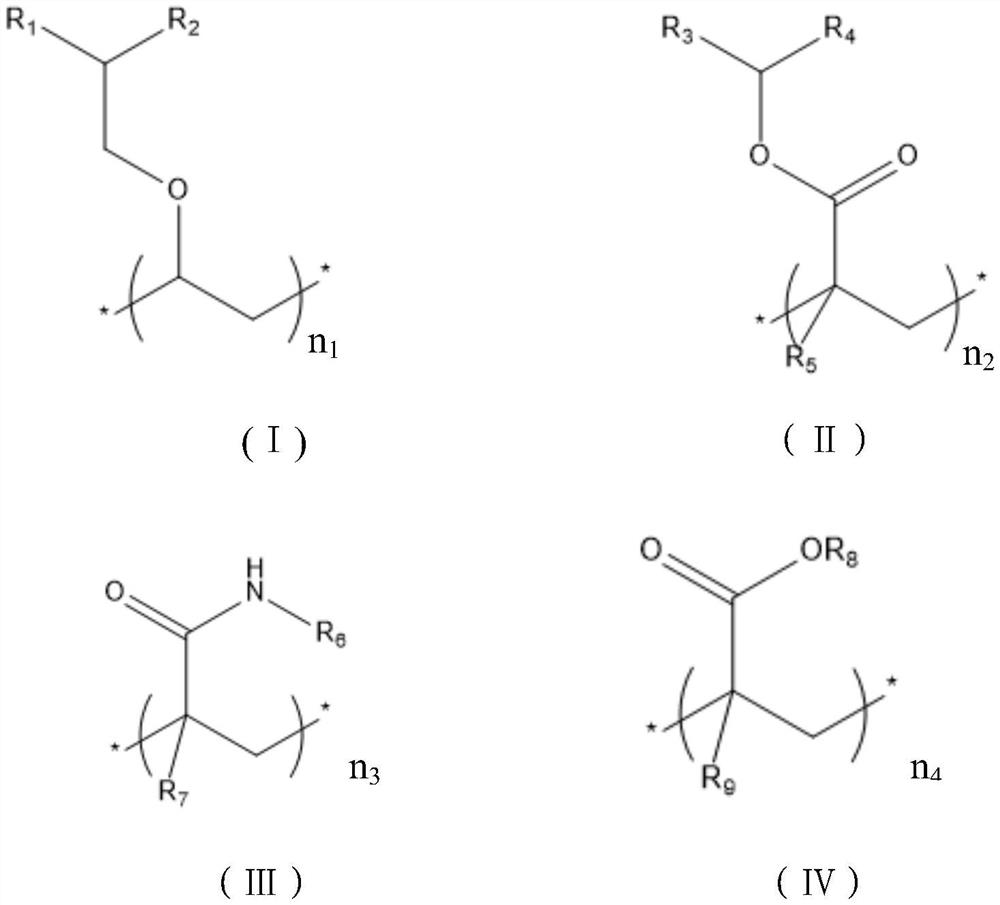

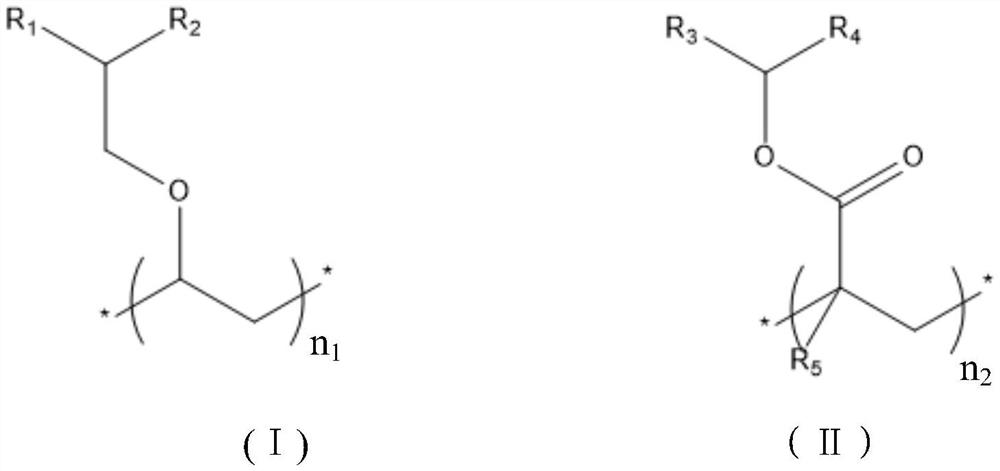

[0143] Examples 9-13 are respectively a kind of binder, and its chemical formula can be represented by formula V, and the difference between them and Example 1 lies in the specific composition.

[0144]

[0145] Among them, R 1 ~R 9 The substituents are shown in Table 4, a, b, c, and d are mole percentages, and their values are shown in Table 9 and Table 10.

[0146] Table 9

[0147] serial number R 1

R 2

R 3

R 4

R 5

R 6

R 7

R 8

R 9

Example 9 -H -H -H -H -H -H -CF 3

-H -H Example 10 -CH 3

-H -H -H -H -H -CF 3

-H -H Example 11 -CH 3

-CH 3

-CH 3

-H -H -H -H -H -CH 3

Example 12 -H -H -CH 3

-H -H -H -H -H -CH 3

Example 13 -H -H -CH 3

-H -H -H -CF 3

-H -CH 3

[0148] Table 10

[0149]

[0150]

[0151] After testing, the Raman shifts of the binders in Examples 5-13 are shown in Table 11.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com