Thermal growth Cr203 film type M Cr nano composite plating and producing process and application

A nano-composite and thermal growth technology, applied in coatings, electrolytic coatings, etc., can solve the problems of insufficient composite content to form protection, uneven distribution of Cr particles, and little research progress, and achieve good oxidation resistance. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

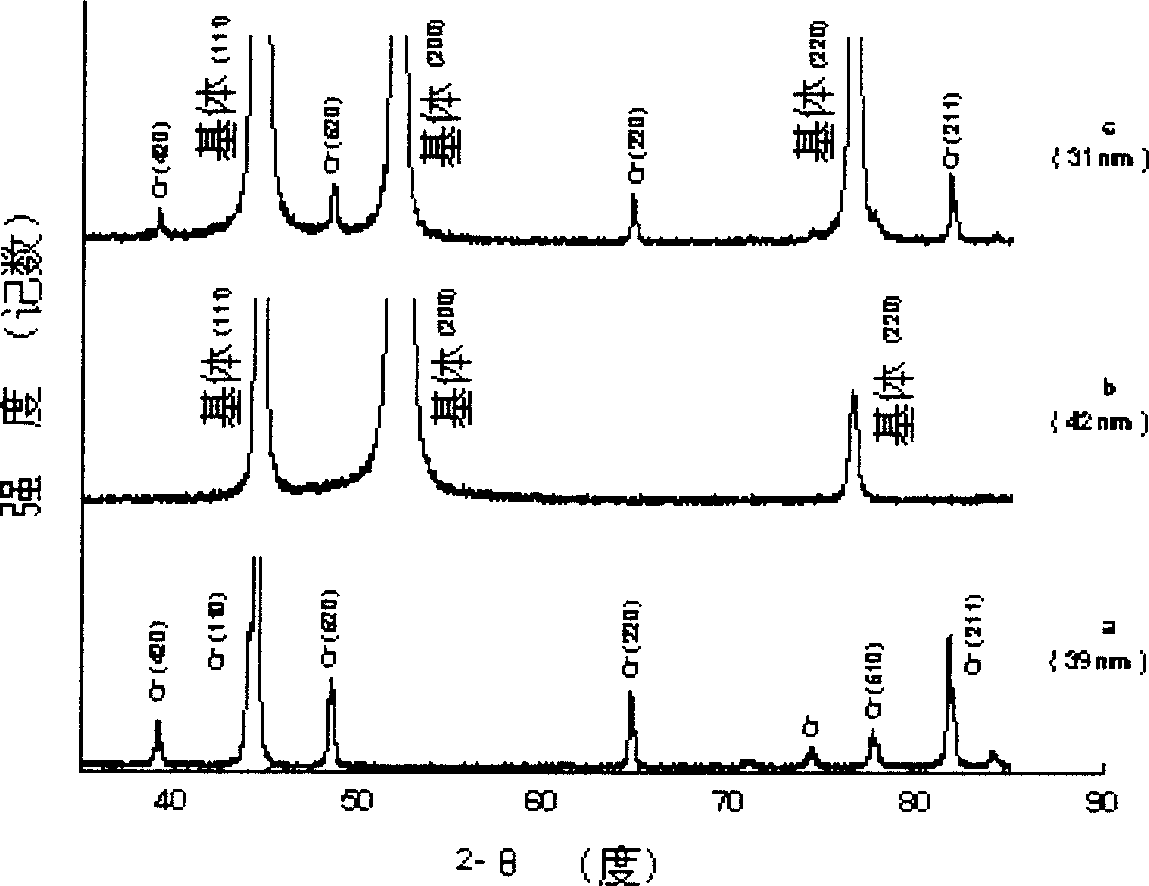

Embodiment 1

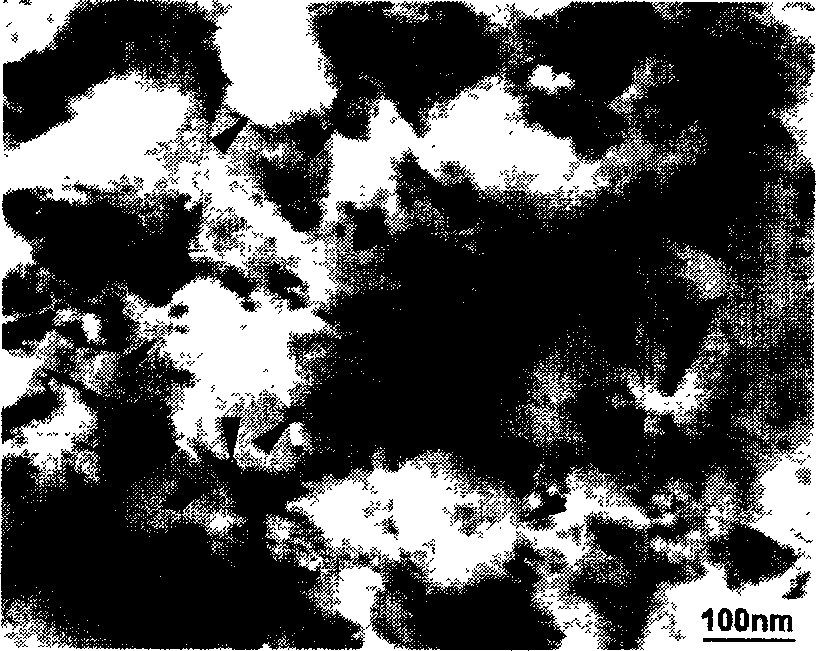

[0047] The composition and structural characteristics of the nanocomposite coating are introduced below, taking the average size of the composite Cr particle as 39nm as an example (the characteristics of nanocomposite coatings with other sizes are similar). figure 1 The surface morphology of the obtained Ni-9.6Cr nanocomposite coating. The energy spectrum analysis shows that the scattered particles are Cr-rich nanoparticles, and the white island-like particles are Ni-coated Cr structures. The crystal grain size of nano-Cr powder, single Ni coating and Ni-9.6Cr composite coating is determined by XRD, and the results are as follows: figure 2 shown. Wherein, a is the XRD diffraction pattern of the nano-Cr powder, and the average grain size calculated by Scherrer according to the half width of the diffraction peak obtained is 39nm; b is the XRD diffraction pattern of the single Ni coating, and the average grain size is 42nm; c is the XRD diffraction pattern of the composite coa...

Embodiment 2

[0049] This embodiment limits the nano-Cr powder of compound different size, can grow continuous Cr 2 o 3 The content range of oxide film.

[0050] Pic 4-1 and Figure 4-2 The shaded parts of the nanocomposite coatings can grow Cr at 800°C and 900°C respectively 2 o 3 The Cr content range of the film. It can be seen from the figure that the lower limit and the minimum content (that is, the critical content) of the composited Cr particles are not only related to the size of the composited particles, but also related to the ambient temperature. For example, when the average size of the composite particles is 20nm, 29nm and 80nm, the critical content required at 800°C is 7.3%, 9.6% and 11.2% by mass percentage respectively, while at 900°C the corresponding value becomes 7.5% , 10.9% and 13%. The results indicated that the growth of Cr 2 o 3 The critical Cr content required by the film increases; when the size of the composite nanoparticles is constant, the corresponding...

Embodiment 3

[0052] Example 2 has shown that no matter the oxidation temperature is 800°C or 900°C, as long as the Cr content is in the above shaded area, the nanocomposite coating can grow Cr 2 o 3 membrane. This example is provided in Figure 4-2 A nanocomposite coating Ni-10.9%Cr with a composite average particle size of 39nm in the range (900°C) grows Cr when oxidized 2 o 3 The oxidation characteristics and performance of the film are compared with a single pure Ni coating without nano-Cr particles and a Ni substrate for oxidation characteristics.

[0053] Figure 5 Oxidation kinetics curve of Ni substrate, single Ni coating, and Ni-10.9Cr nanocomposite coating at 900°C for 24 hours. It can be seen from the figure that the Ni-10.9Cr nano-oxidation rate decreases sharply. The calculated oxidation parabolic constants of the three samples are 6.9×10 -11 , 9.7×10 -11 , 1.7×10 -12 g 2 / cm 4 ·s. Among them, the oxidation rate of the nanocomposite coating is 40 times lower than th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com