Nano titanium dioxide/copper sulphide nano composite material

A nano-composite material and nano-titanium dioxide technology, applied in nanotechnology, nanotechnology, chemical/physical process and other directions, can solve the problems of low photocatalytic efficiency and low utilization rate of solar energy, and achieve simple preparation equipment, enhanced light absorption range, The effect of improving the photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

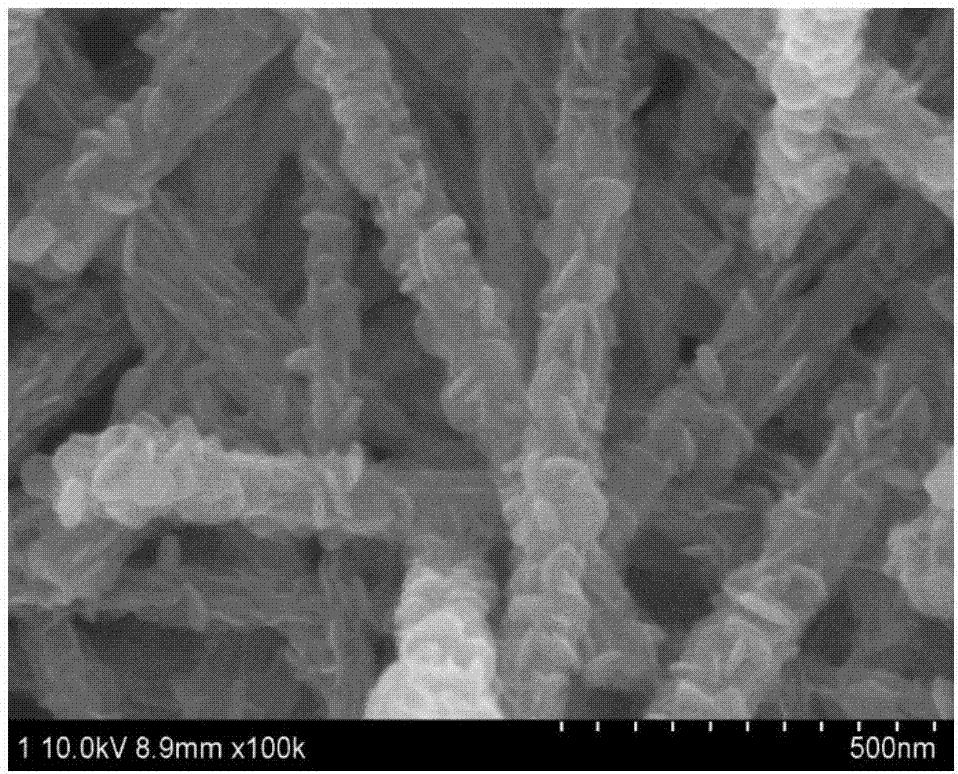

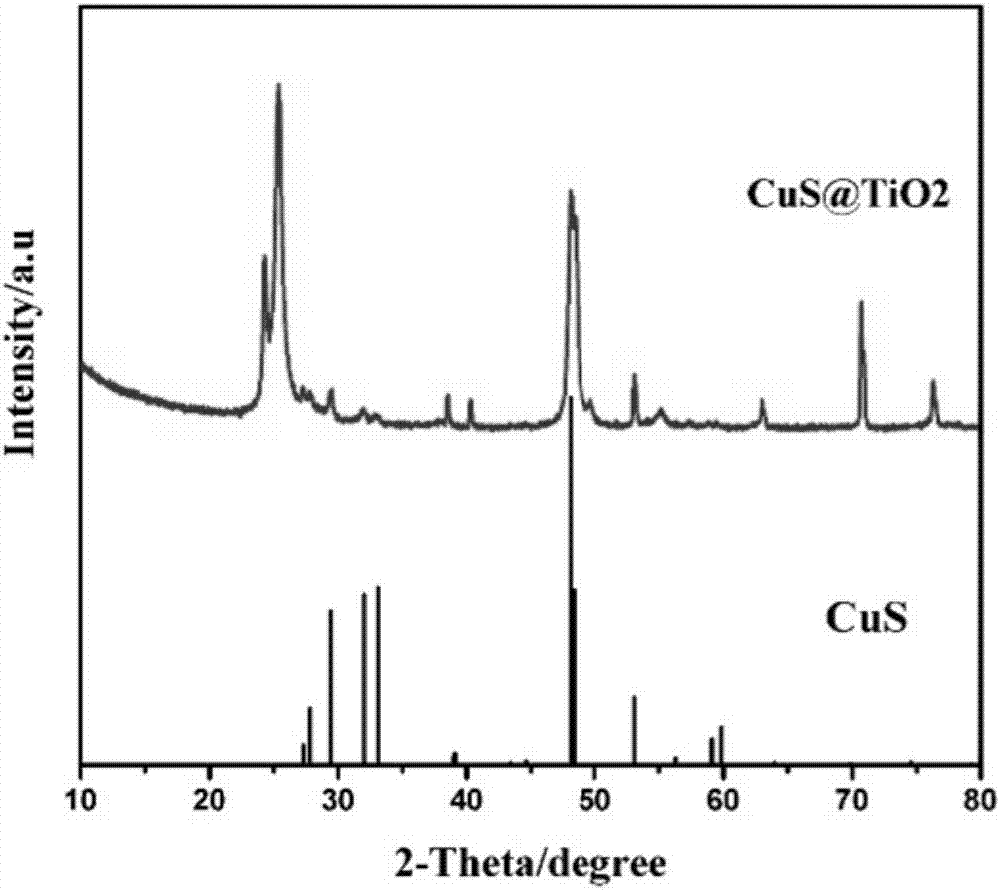

[0014] Example 1, (1) Hydrothermal treatment was performed on a titanium sheet to obtain titanium dioxide nanowires on the surface of the titanium sheet; (2) The titanium sheet treated in step 1 was immersed in a mixed aqueous solution of copper chloride and sodium thiosulfate, and passed Hydrothermally heated at 110℃ for 10 hours, then the CuS nanosheet composite TiO is obtained 2 Nanocomposite materials. Wherein, in the mixed solution of copper chloride and sodium thiosulfate, the concentration of copper chloride and sodium thiosulfate is 0.05 mol / L. Such as figure 1 The SEM picture shows that the copper sulfide nanosheets are uniformly grown on the surface of the titanium dioxide nanowires. figure 2 The XRD pattern shows that the nanocomposite contains copper sulfide, and the energy spectrum shows that the composite contains various elements ( Image 6 ),Such as Figure 5 For CuS@TiO 2 TEM characterization of NW nanocomposites shows that the successful combination of copper ...

Embodiment 2

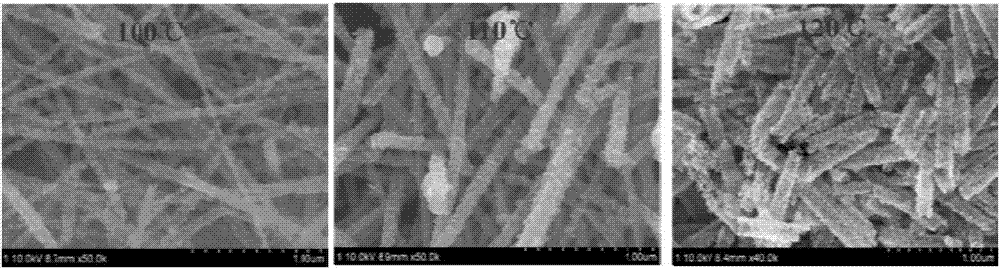

[0015] Example 2: (1) Hydrothermal treatment was performed on the titanium sheet to obtain titanium dioxide nanowires on the surface of the titanium sheet; (2) The titanium sheet treated in step 1 was immersed in a mixed aqueous solution of copper chloride and sodium thiosulfate, By changing the hydrothermal temperature under 10h hydrothermal conditions, different morphologies can be obtained. Such as image 3 Shown as CuS@TiO 2 The SEM image of the NW nanocomposite material shows that after 10 hours of hydrothermal time, the nanocomposite material obtained at a hydrothermal temperature of 110°C has a good morphology, and copper sulfide is well distributed on the surface of the nanowire.

Embodiment 3

[0016] Example 3, (1) Hydrothermal treatment was performed on the titanium sheet to obtain titanium dioxide nanowires on the surface of the titanium sheet; (2) The titanium sheet treated in step 1 was immersed in a mixed aqueous solution of copper chloride and sodium thiosulfate, and Under the hydrothermal temperature of 110℃, the CuS@TiO with different morphologies can be obtained by changing the hydrothermal reaction time 2 NW nanocomposite materials. Such as Figure 4 The SEM image shows that the nanocomposite material obtained under the hydrothermal temperature of 110℃ and the hydrothermal time of 10h has a good morphology, and the two are well dispersed, avoiding the aggregation of copper sulfide on the surface of the titanium dioxide nanowire .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com