Preparation method of bi-component epoxy resin adhesive

A technology of epoxy resin glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve problems such as difficult for users to use normally, environmental pollution, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

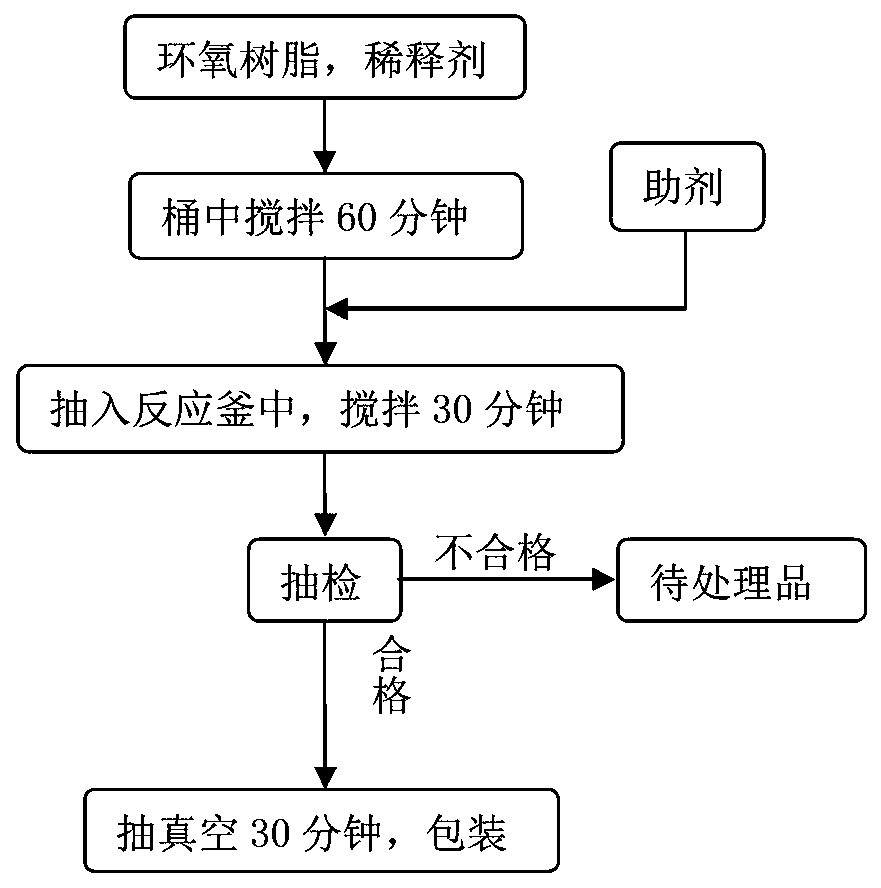

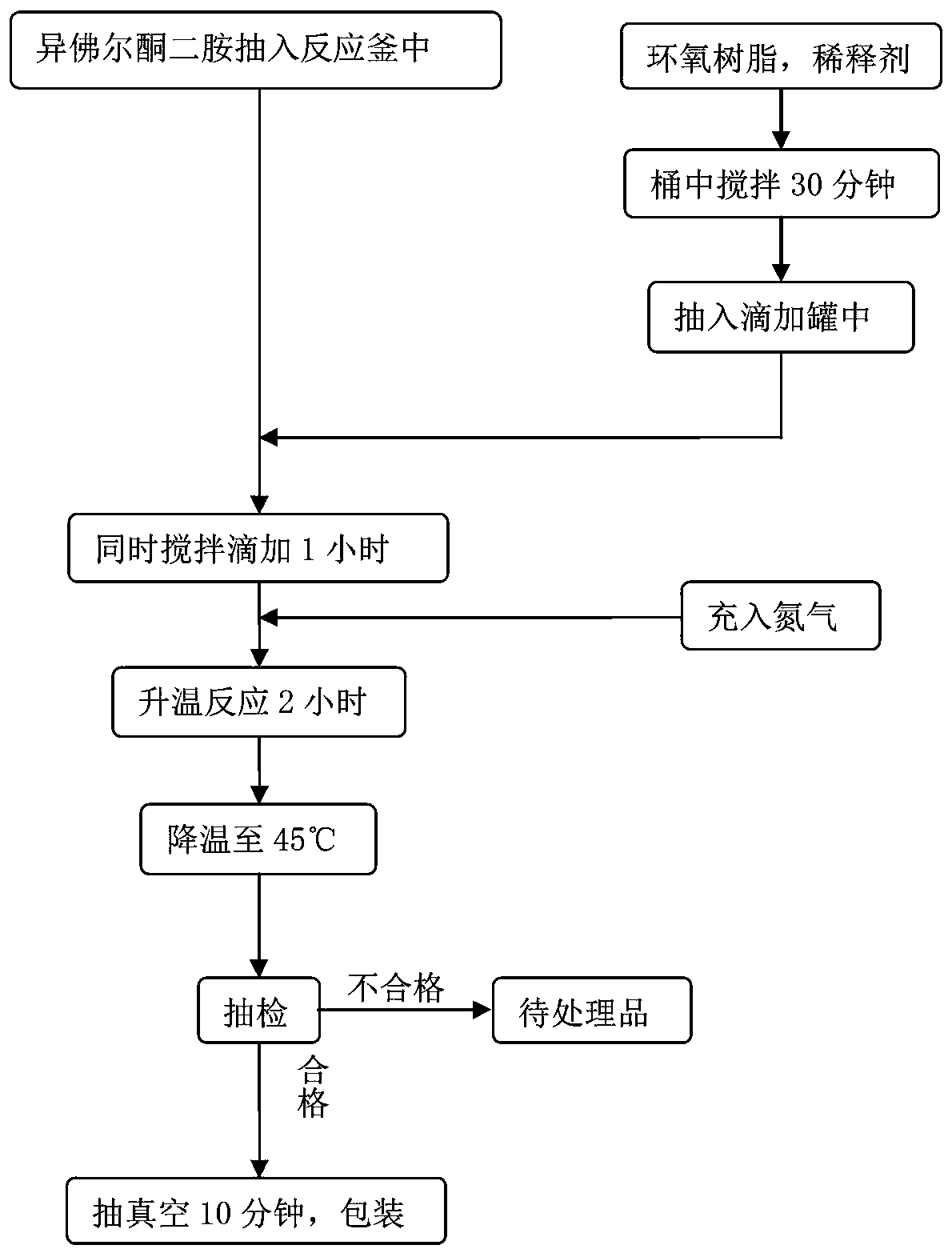

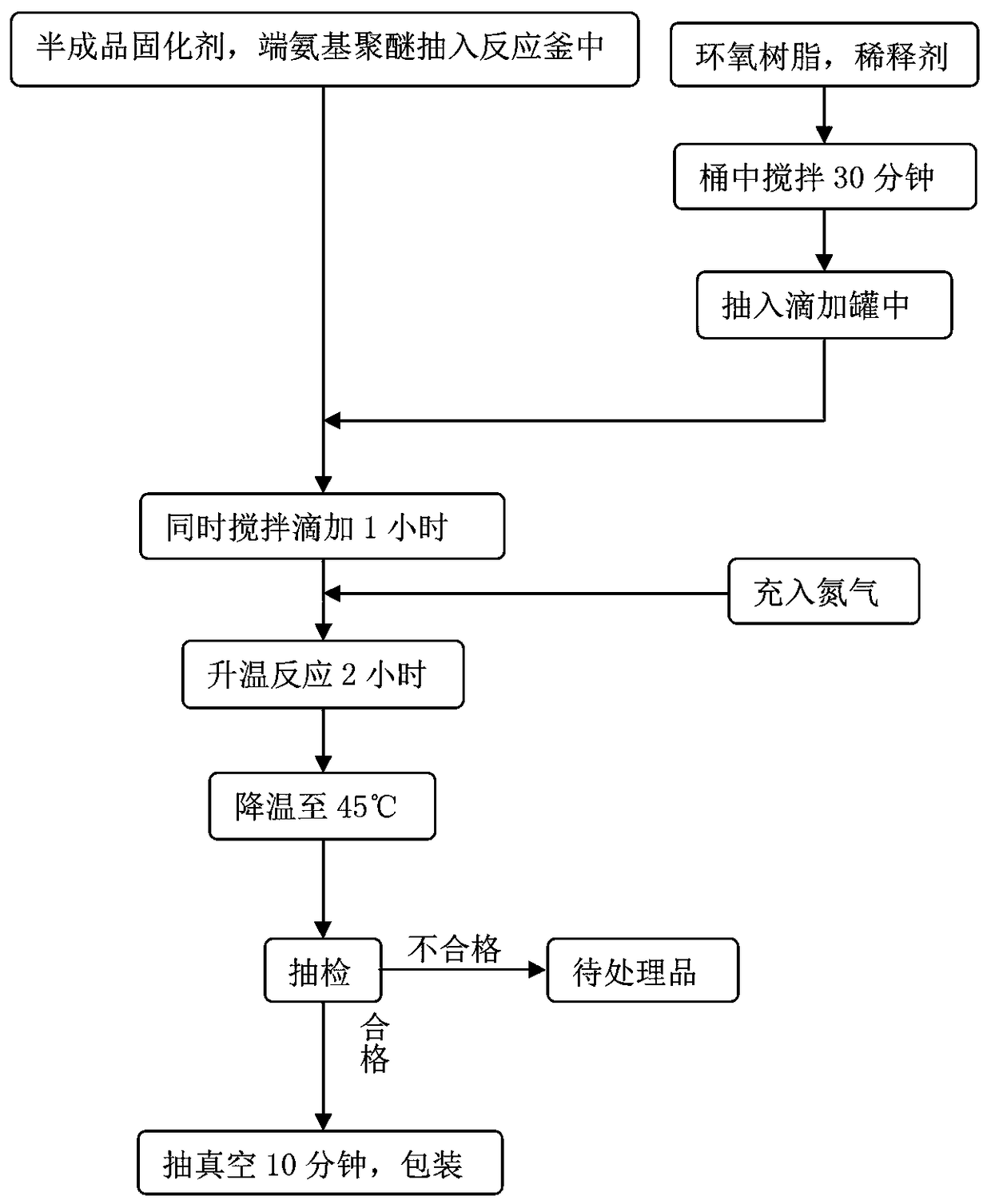

[0018] The manufacturing method of the two-component epoxy resin glue of the present invention is divided into A glue and B glue: A glue adopts the single-epoxy propylene oxide benzyl ether as an auxiliary agent and adds it into the two-component epoxy resin according to the ratio on the formula. Among the phenol A type epoxy resins, the use viscosity of the low molecular weight epoxy resin in supercooled state at room temperature is further reduced, so that while improving the convenience of operation, the odor of solvent-free epoxy will not be lost, and it will be free. Pollution, low shrinkage and other advantages. Moreover, it can also increase the operation time of epoxy resin AB glue after mixing, thereby improving the defoaming property of the glue, reducing the amount of additives used, and improving the overall permeability of the cured product; Phorone diamine reacts with bisphenol A epoxy resin to obtain an amine adduct containing residual amino active hydrogen with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com