Channel structure of vacuum cleaner

A technology of vacuum cleaner and channel structure, applied in the direction of suction filter, etc., can solve the problems of increasing the volume of the dust collecting device and reducing the working efficiency, and achieve the effect of reducing the volume, improving the dust collecting efficiency and increasing the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

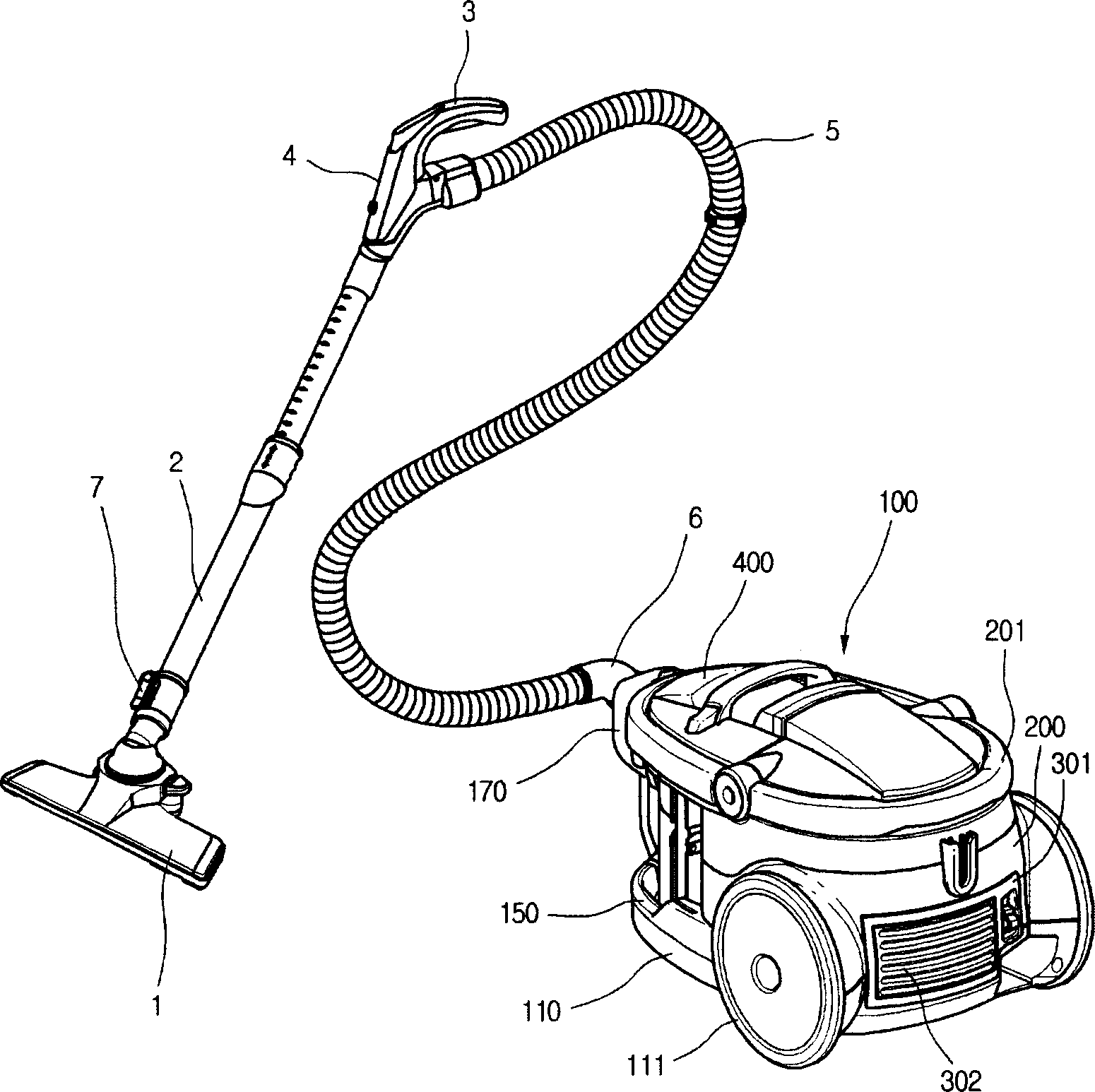

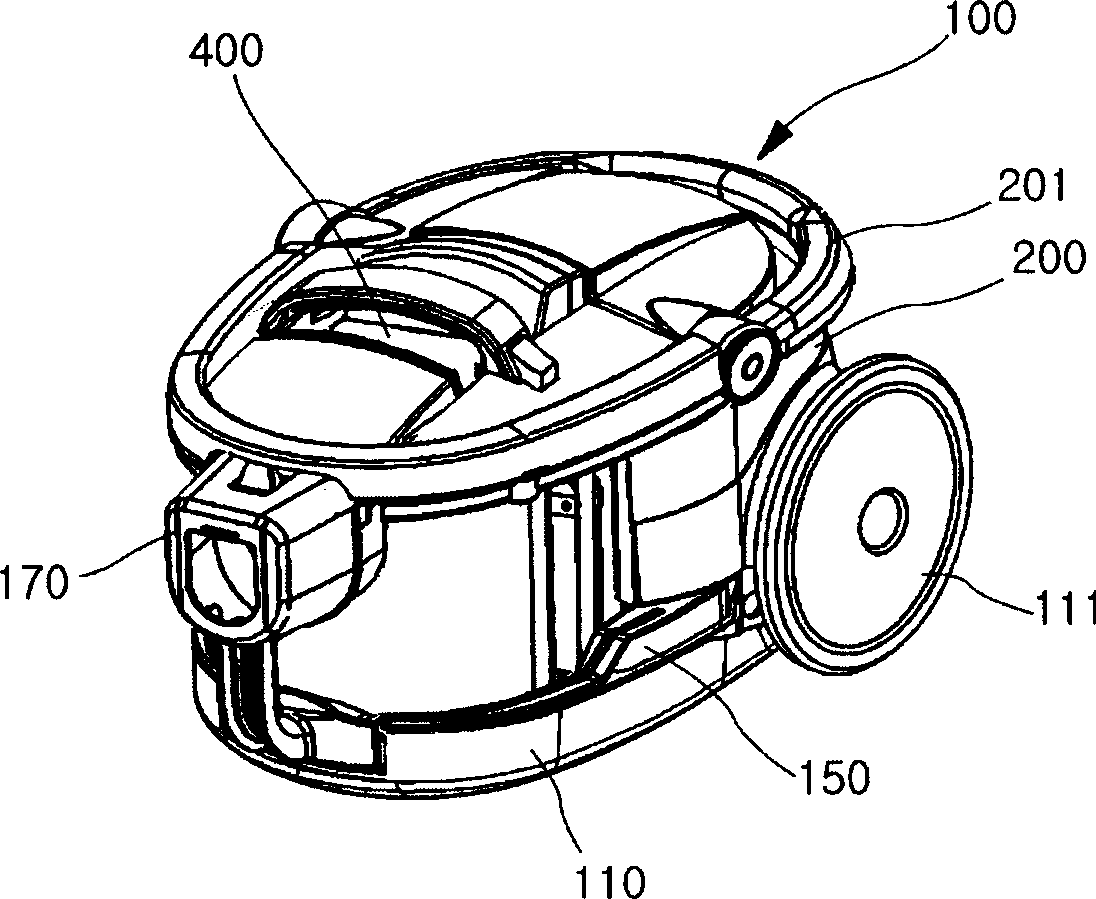

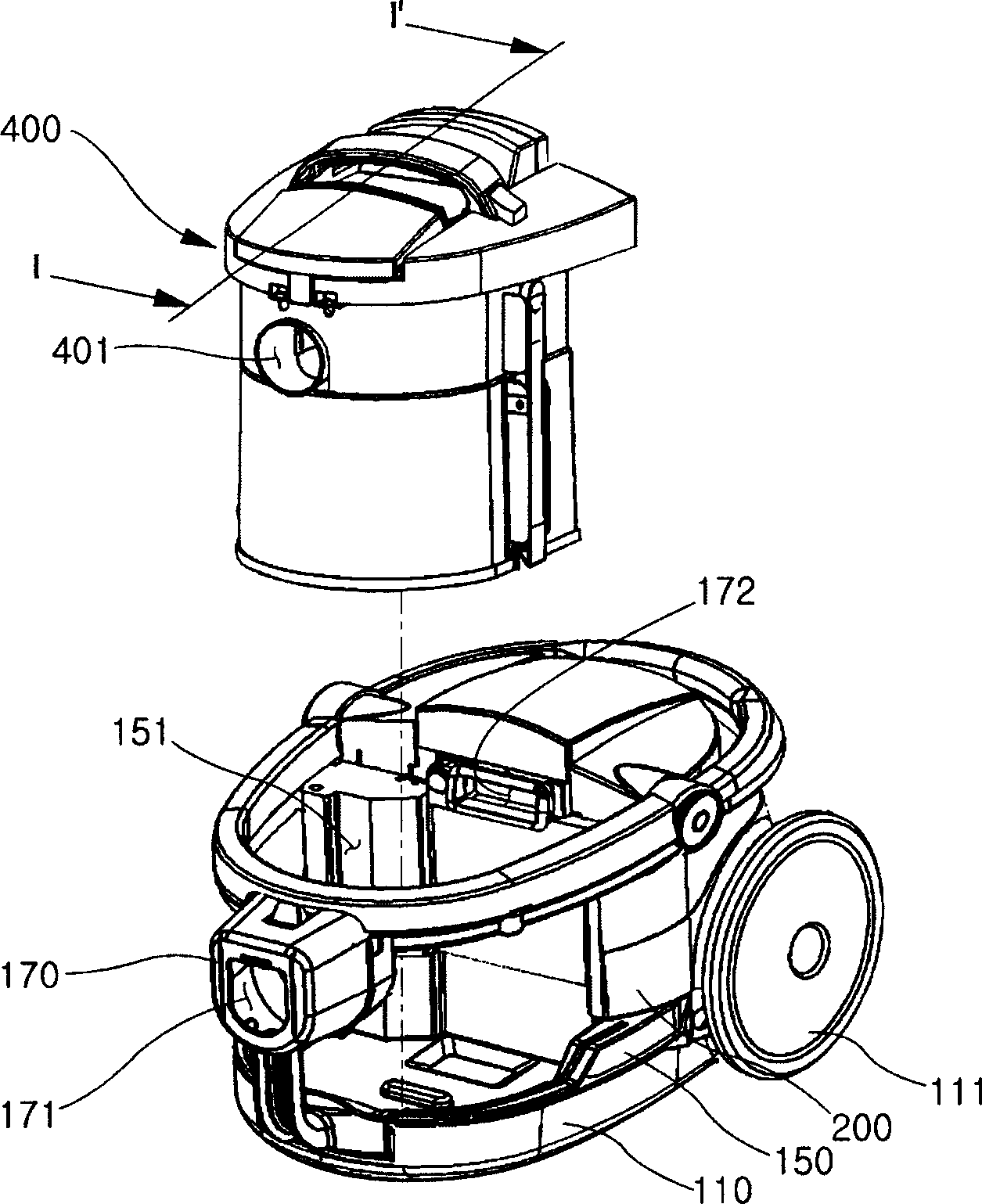

[0019] figure 1 The three-dimensional structure diagram of the vacuum cleaner provided by the present invention. Such as figure 1 As shown, the vacuum cleaner provided by the present invention includes a body 100 and a suction pipeline connected to the suction side of the body 100 . The inside of the main body 100 is at least installed with a suction fan and a dust collection device, so that the external air can be sucked in and the foreign matter can be filtered out and then discharged to the outside. The suction pipeline is a pipeline that utilizes the suction inside the vacuum cleaner body 100 to suck air and foreign matter together. Specifically, the suction pipeline includes: a suction nozzle 1 that sucks air mixed with foreign matter from the outside; an extension tube 2 that extends from the suction nozzle 1 and can be stretched according to the use state; 2. The operating handle 3 at the end; the operating part 4 that is arranged on the front portion of the operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com