Rail grinding dust-precipitating system and rail grinding wagon

A technology of dust collection system and track, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of unable to change the trajectory of large particle dust and low dust collection efficiency, so as to reduce workload, improve dust collection efficiency, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

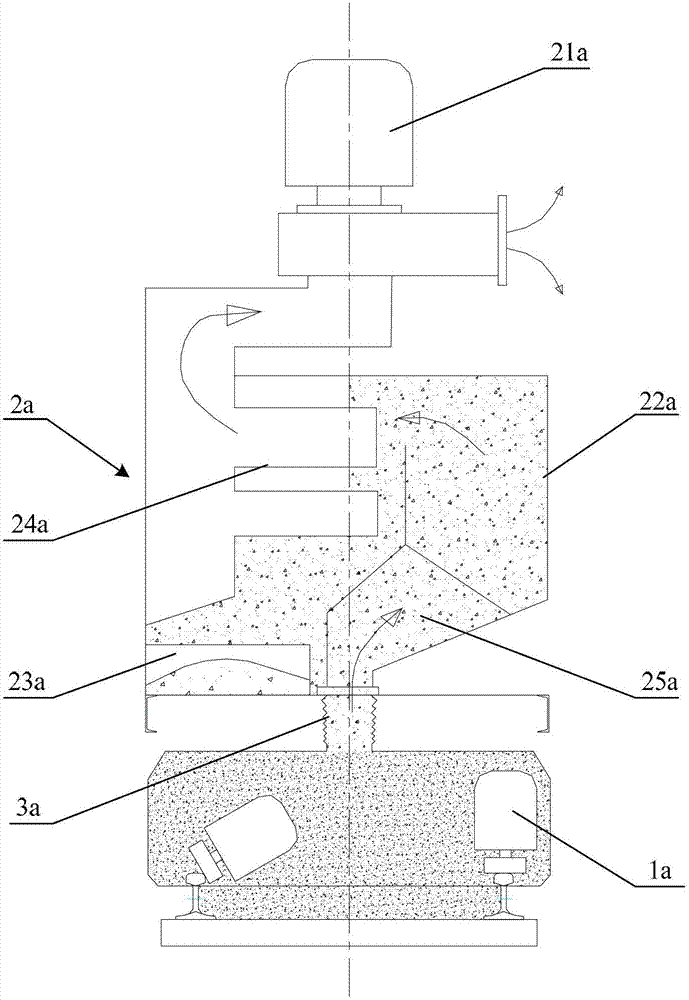

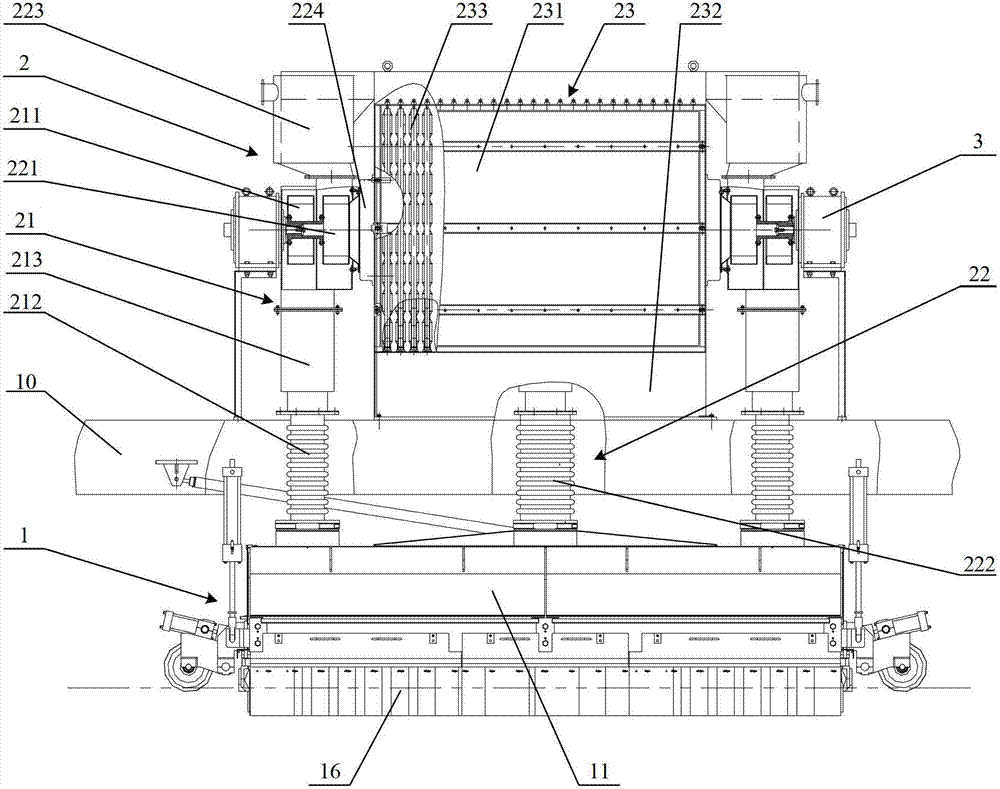

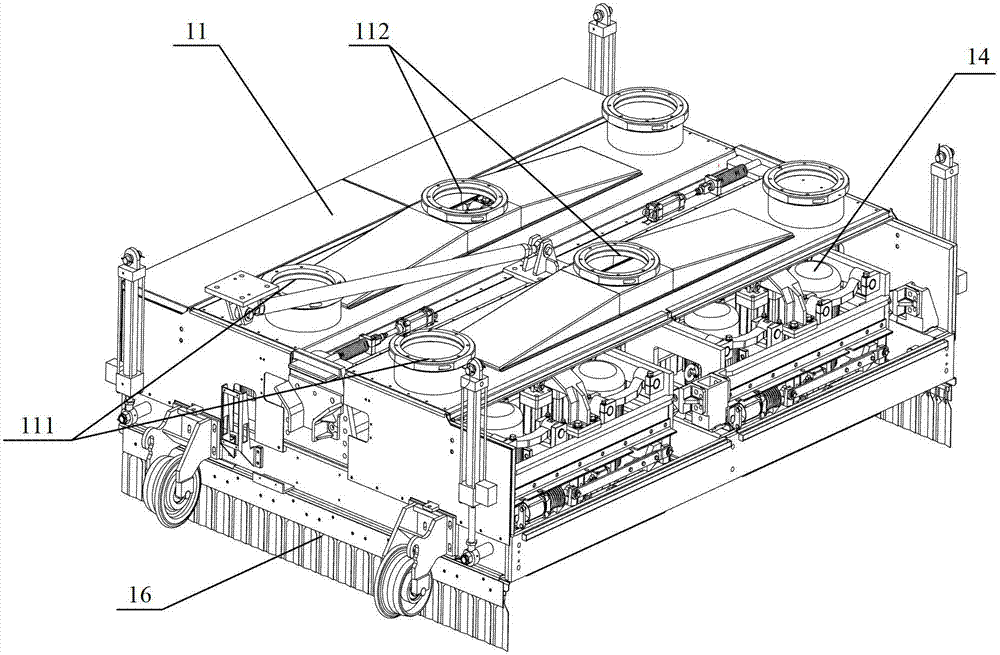

[0037] refer to Figure 2~4 , figure 2 Schematic diagram of the structure of the track grinding and dust collection system provided by the embodiment of the present invention; image 3 A three-dimensional view of a grinding device provided by an embodiment of the present invention; Figure 4 for image 3 Front view of the grinding device shown.

[0038] Such as Figure 2~4 As shown, the track grinding and dust collection system provided in this embodiment includes a grinding device 1 and a dust collecting device 2. The dust collecting device 2 is arranged above the grinding device 1. Specifically, the grinding device 1 can be arranged on the frame 10 of the grinding vehicle. The bottom part can connect the grinding device 1 to the vehicle frame 10 through a connecting rod, the dust collecting device 2 can be arranged on the top of the vehicle frame 10, and the dust collecting device 2 and the vehicle frame 10 are connected by bolts or welding.

[0039] The grinding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com