Rolling brush structure with spiral blades

A helical and vane technology, applied in the field of roller brush structure, can solve the problems of insufficient axial thrust, unsatisfactory cleaning effect, messy and uneven dust movement direction, etc., and achieve the effect of improving dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

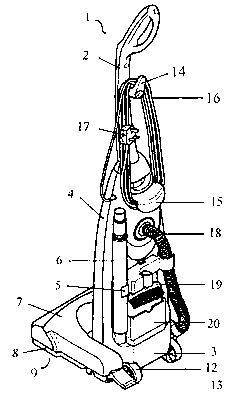

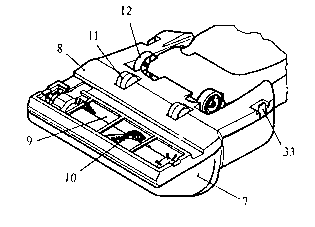

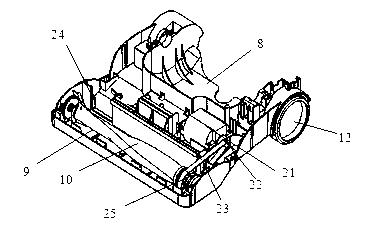

[0039] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

[0040] The rolling brush structure with helical blades of the present invention is installed inside the suction nozzle below the upright vacuum cleaner. like Figure 1 to Figure 3 As shown, the upright vacuum cleaner includes a handle 2 located on the upper part of the body 1, the front part of the body 1 is a front cover 4 combined with the bottom case 3, and a spare rigid suction pipe 6 is plugged into the spare parts rack 5 on the side wall of the bottom case 3 , The bottom of the body 1 is provided with a suction nozzle 9 that is combined with a suction nozzle upper cover 7 and a suction nozzle chassis 8 through a hook 33 along the ground to suck air containing foreign substances. A suction port 24 is formed on one side behind the rolling brush structure in the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com