Low voltage driven knife-type gate valve body

A knife gate valve, low voltage technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of large system resistance, limited sealing strength, inability to rotate, etc., to increase system resistance, improve sealing effect, and not easy to rust deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

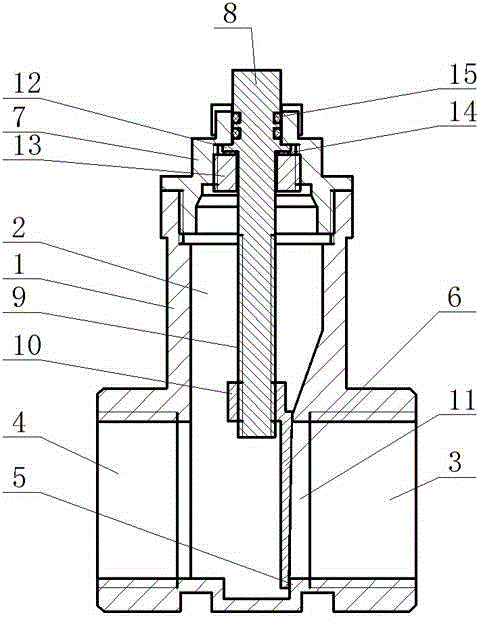

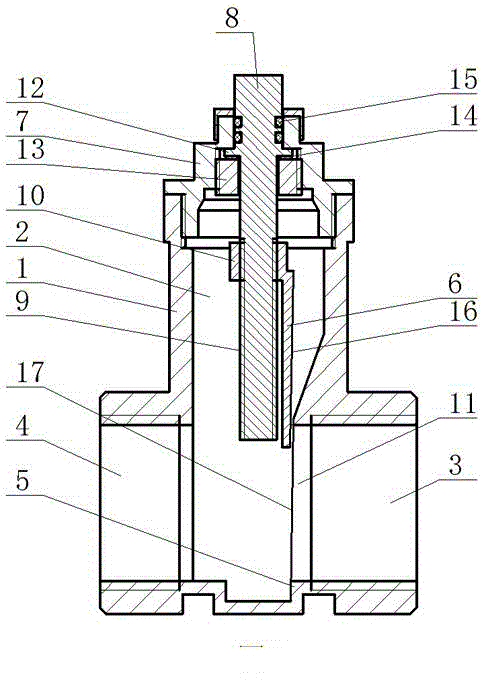

[0008] The low-voltage driven knife-type gate valve body of the present invention includes a valve body 1, a cavity 2 is arranged in the valve body 1, one side of the lower part of the cavity 2 communicates with the pipe joint 3 at the inlet end, and the other side of the lower part of the cavity 2 communicates with the outlet The end pipe joint 4 is connected, and the position where the cavity 2 communicates with the inlet end pipe joint 3 is provided with an annular step 5, and the inside of the annular step 5 forms a water inlet channel 11 communicated with the inlet end pipe joint 3, and the gate 6 is installed in the cavity 2 , the gate 6 is closely matched with the annular step 5, the valve seat 7 is installed on the top of the cavity 2, the valve stem 8 is arranged inside the valve seat 7, the valve stem 8 and the valve seat 7 are sealed by a seal, and the lower part of the valve stem 8 is provided with an external thread 9. The screw sleeve 10 is installed on the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com