Heating type stock bin breathing device

A breathing device and heating technology, applied in the field of silos, can solve the problems of unsmooth loading, difficult to clean up, heavy replacement and maintenance workload, etc., so as to reduce the frequency of high-altitude work, reduce workload and risk , The effect of convenient replacement of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

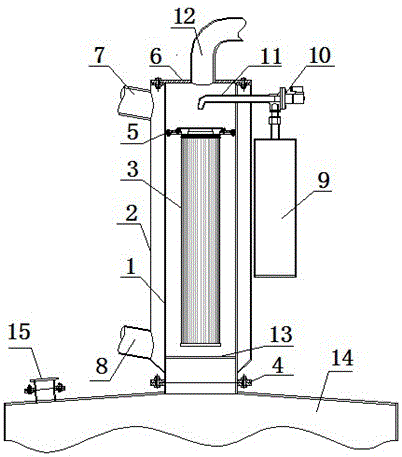

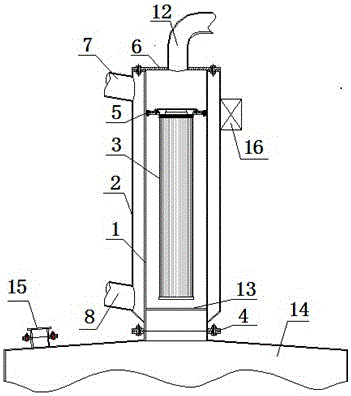

[0040] Such as figure 1 As shown, a kind of heating type silo breathing apparatus described in this embodiment comprises:

[0041] The body system is composed of inner shell 1, outer shell 2, filter element 3, connecting flange 4, fixed filter element flange 5, and cover plate 6. The silo body is assembled with the silo 14 through the connecting flange 4. There is a safety valve 15, the outer shell 2 is welded on the inner shell 1, the filter element 3 is fixed by the filter element flange 5, the cover plate 6 is matched with the top of the body, and the inner shell 1 is also provided with a protective device to prevent the filter element 3 from falling into the material bin 14. slip through the net 13;

[0042] A heating system consisting of a heat fluid medium inlet pipe 7, a heat fluid medium outlet pipe 8, and a jacket formed by the inner shell 1 and the outer shell 2. The heat fluid medium inlet pipe 7 enters the jacket from the upper part of the shell 2, and the heat fl...

Embodiment 2

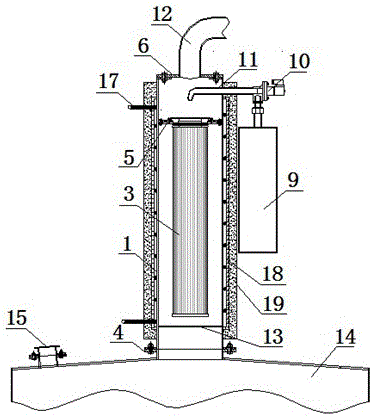

[0048] Such as image 3 As shown, a kind of heating type silo breathing apparatus described in this embodiment comprises:

[0049] A body system consisting of an inner shell 1, a filter element 3, a connecting flange 4, a fixed filter element flange 5 and a cover plate 6, the filter element 3 is set in the inner wall 1 through the fixed filter element flange 5, and the warehouse body is set through the connecting flange 4 is assembled with the silo 14, the top of the silo 14 is equipped with a safety valve 15, and the cover plate 6 is arranged on the top of the inner wall 1 of the silo. The leak-proof net 13 in the storehouse 14;

[0050] A heating system consisting of heat tracing pipe 17, aluminum foil 18 and insulation layer 19. The heat tracing pipe 17 is wound on the outside of the inner wall 1. A layer of aluminum foil 18 is provided;

[0051] A cleaning system composed of a cylinder 9, a solenoid valve 10, a pulse pipeline 11 and an exhaust pipeline 12, the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com