Compensation type multipurpose annular blowout preventer

An annular blowout preventer, a multi-purpose technology, is applied in drilling equipment, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of unadjustable self-sealing well sealing capacity, easy damage of the main rubber sleeve in the annular space, and the inner liner Holes are not round and other problems, to achieve the effect of light weight, low maintenance cost, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

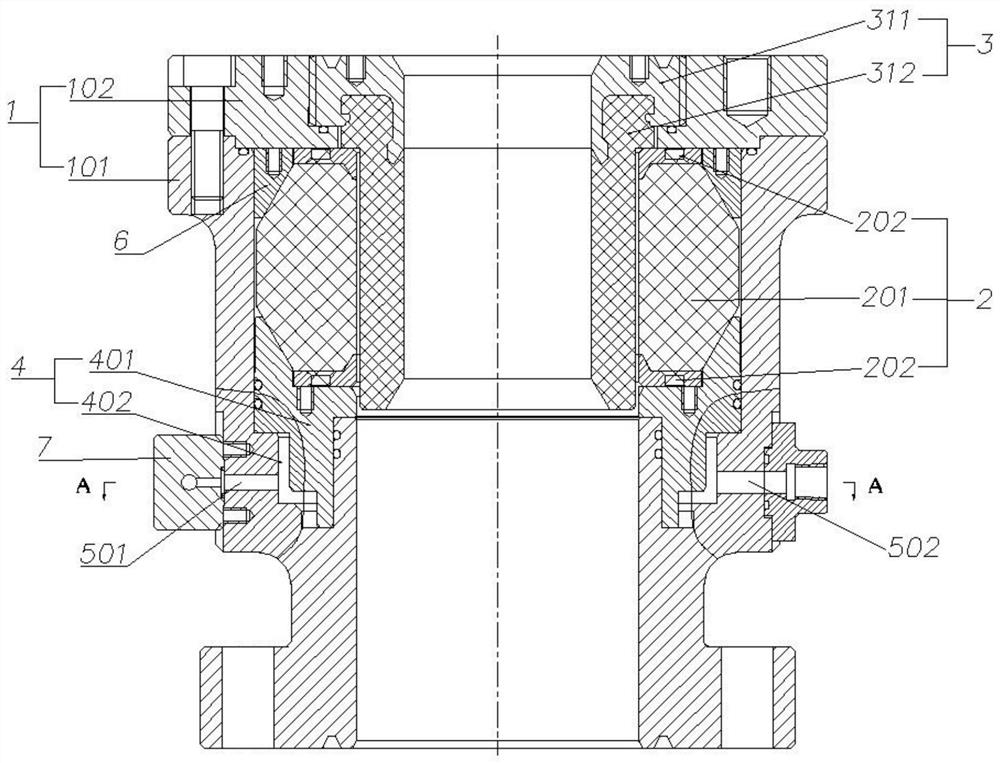

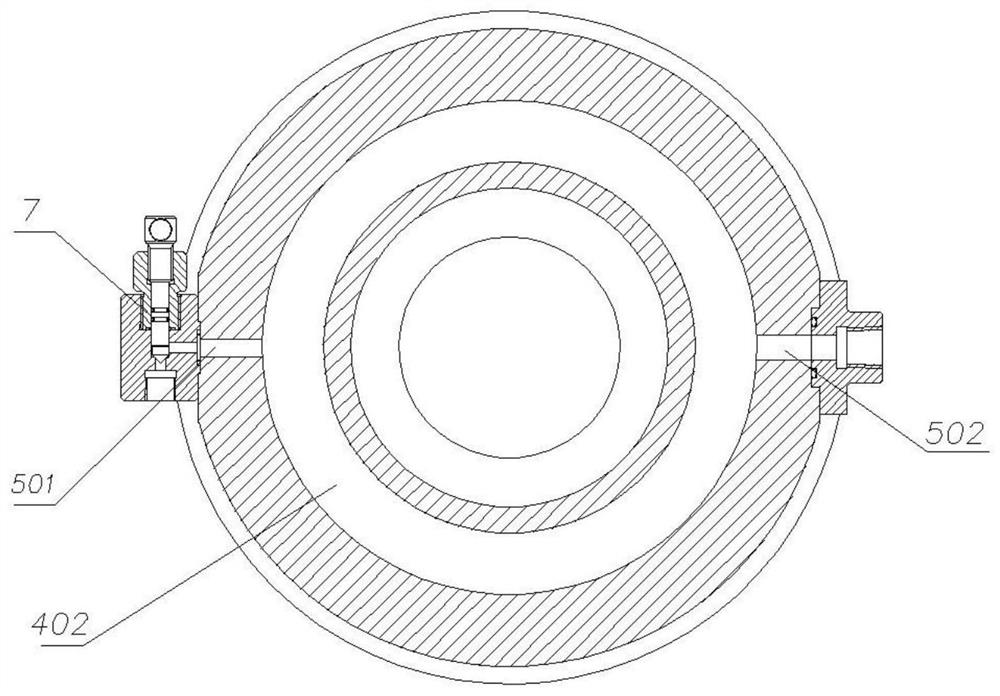

[0064] Such as figure 1 , figure 2 , image 3 As shown, the annular blowout preventer includes a shell 1, a main rubber sleeve assembly 2, and a secondary rubber sleeve assembly 3 arranged coaxially from the outside to the inside, which are located inside the shell 1 and arranged below the main rubber sleeve assembly 2 for The piston assembly 4 that squeezes the main rubber sleeve assembly 2 and the oil passage provided on the housing 1 and communicated with the piston assembly 4 .

[0065] In this embodiment, the housing 1 includes a housing body 101 and a flange 102 disposed on the upper end of the housing body 101 , and the housing 1 penetrates up and down inside.

[0066] The main rubber sleeve assembly 2 is set inside the shell body 101, including the main rubber sleeve 201 and two ring skeletons 202 respectively arranged on the upper end and the lower end of the main rubber sleeve 201, where the two ring skeletons 202 and the main rubber sleeve 201 are integrated str...

Embodiment 2

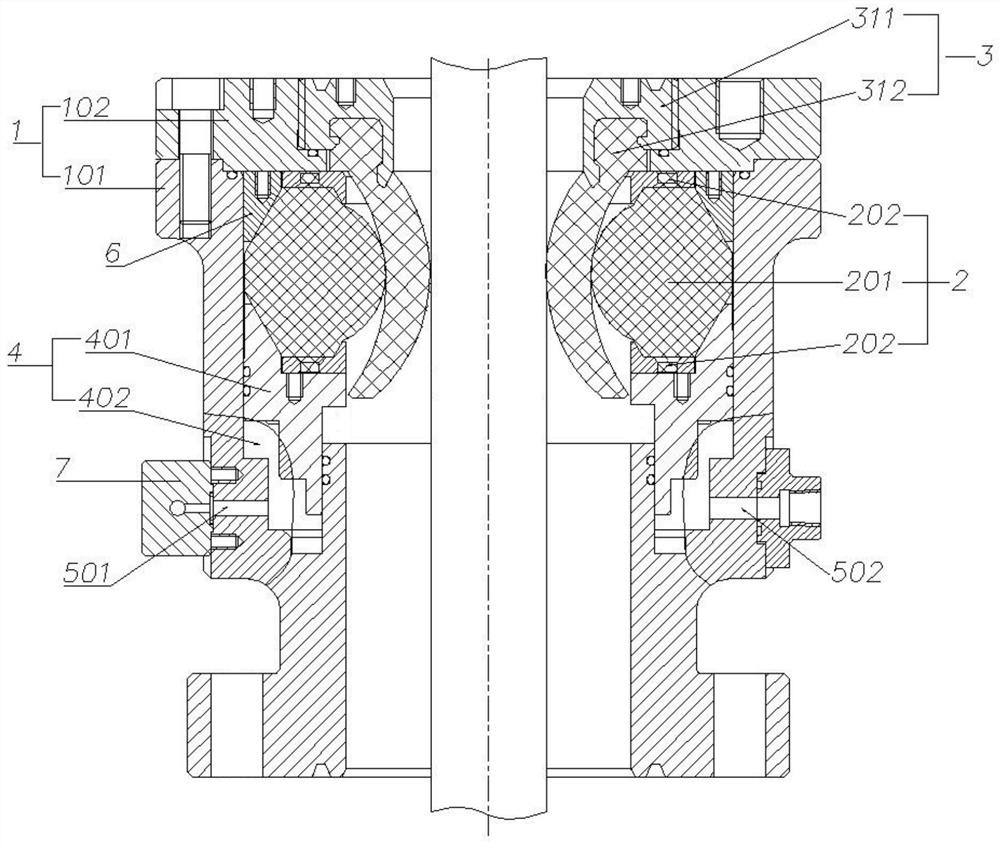

[0077] Such as Figure 4 As shown, the annular blowout preventer includes a shell 1, a main rubber sleeve assembly 2, and a secondary rubber sleeve assembly 3 arranged coaxially from the outside to the inside, which are located inside the shell 1 and arranged below the main rubber sleeve assembly 2 for The piston assembly 4 that squeezes the main rubber sleeve assembly 2 and the oil passage provided on the housing 1 and communicated with the piston assembly 4 .

[0078] In this embodiment, the housing 1 includes a housing body 101 and a flange 102 disposed on the upper end of the housing body 101 , and the housing 1 penetrates up and down inside.

[0079] The main rubber sleeve assembly 2 is set inside the shell body 101, including the main rubber sleeve 201 and two ring skeletons 202 respectively arranged on the upper end and the lower end of the main rubber sleeve 201, where the two ring skeletons 202 and the main rubber sleeve 201 are integrated structure. The inside of t...

Embodiment 3

[0086] Such as Figure 5 As shown, the annular blowout preventer includes a shell 1, a main rubber sleeve assembly 2, and a secondary rubber sleeve assembly 3 arranged coaxially from the outside to the inside, which are located inside the shell 1 and arranged below the main rubber sleeve assembly 2 for The piston assembly 4 that squeezes the main rubber sleeve assembly 2 and the oil passage provided on the housing 1 and communicated with the piston assembly 4 .

[0087] In this embodiment, the housing 1 includes a housing body 101 and a flange 102 disposed on the upper end of the housing body 101 , and the housing 1 penetrates up and down inside.

[0088] The main rubber sleeve assembly 2 is set inside the shell body 101, including the main rubber sleeve 201 and two annular skeletons 202 respectively arranged on the upper end and the lower end of the main rubber sleeve 201, where the two annular skeletons 202 and the main rubber sleeve 201 are integrated structure. The insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com