Early overflow and leakage monitoring system for well drilling

A monitoring system and overflow technology, which are applied in the automatic control system of drilling, drilling equipment, measurement, etc., can solve the problems of poor measurement accuracy, delayed treatment time, and large mud pool, so as to improve monitoring accuracy and facilitate maintenance operations. , The effect of the system is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

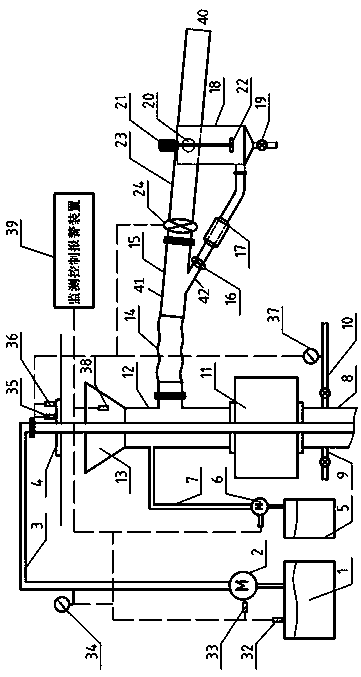

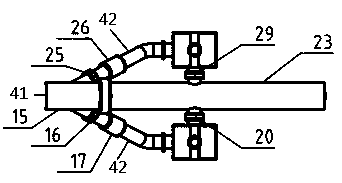

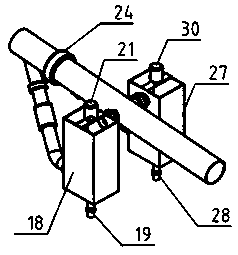

[0019] As the best implementation mode of the present invention, the following combination figure 1 , figure 2 , image 3 The concrete implementation of the present invention is described further:

[0020] The present invention is an early overflow and leakage monitoring system for drilling, including Y-shaped elevated pipe 15, stop valve 1 / 2 16 / 25, buffer tank 1 / 2 18 / 27, cleaning valve 1 / 2 19 / 28, and stop valve Three / four 20 / 29, stirring motor one / two 21 / 30, agitator one / two 22 / 31, overhead pipe 23, pneumatic stop valve 24, mass flow meter one / two 17 / 26, mud tank level gauge 32 , pump stroke sensor 33, metering pump 6, bell mouth liquid level gauge 38, turntable torque sensor 35, turntable speed sensor 36; Y-type elevated pipe 15 includes a main pipe, two measuring tubes, and the two measuring tubes are symmetrical at a certain angle Welded on the main pipe, one end of the Y-shaped elevated pipe 15 is connected with the elevated hose 14, and the other end is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com